HERMS Coil Owners Manual - V1

©Blichmann Engineering, LLC 2018

For replacement parts visit blichmannengineering.com/genuine-replacemnet-parts

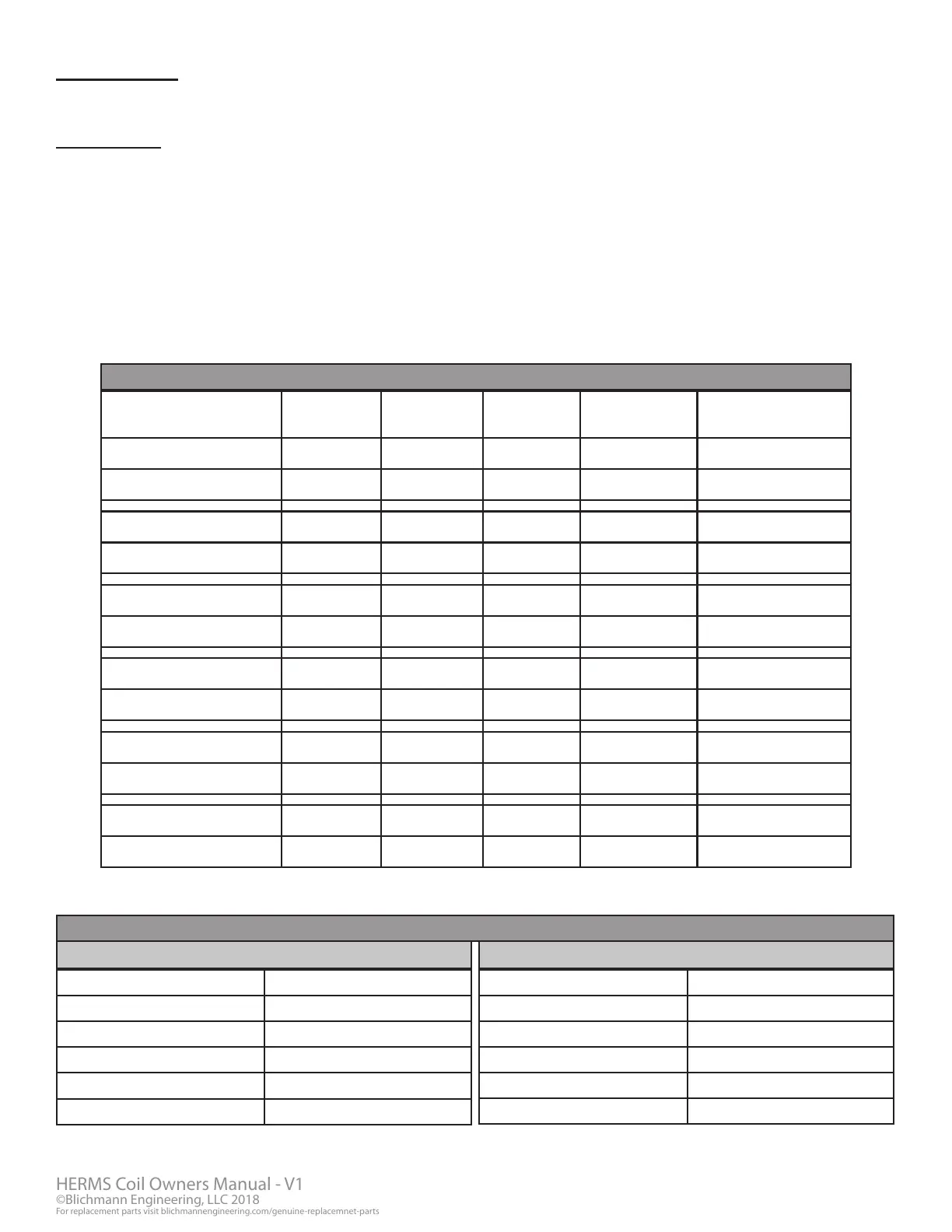

HLT-MT set

differential F°

Strike water vol.

gal

HL Vol. (gal) Time to reach strike

temp.

Time to reach within 5 deg

of strike temp.

55 Gal Kettle without Whirlpool

5 40 48 6 hrs 28 mins 2 hrs 40 mins

55 Gal Kettle with Whirlpool

3 40 48 4 hrs 20 mins 2 hrs 8 mins

30 Gal Kettle without Whirlpool

5 20 25 3 hrs 15 mins 1 hr 20 mins

30 Gal Kettle with Whirlpool

3 20 25 2 hrs 10 mins 1 hr 5 mins

20 Gal Kettle without Whirlpool

5 15 17 2 hrs 25 mins 1 hr

20 Gal Kettle with Whirlpool

3 15 17 1 hr 40 mins 50 mins

15 Gal Kettle without Whirlpool

5 10 13 1 hr 40 mins 40 mins

15 Gal Kettle with Whirlpool

3 10 13 1 hr 5 mins 30 mins

10 Gal Kettle without Whirlpool

5 7 8 1 hr 10 mins 30 mins

10 Gal Kettle with Whirlpool

3 7 8 45 mins 20 mins

7.5 Gal Kettle without Whirlpool

5 5 7 50 mins 20 mins

7.5 Gal Kettle with Whirlpool

3 5 7 30 mins 15 mins

HERMS Heating Times for 7.5-55 Gal MT & HLT

Installation

Install the HERMS Coil with an adjustable wrenche while holding the coil on the inside. DO NOT overtighten.

Operation

With the coil installed, heat the HLT and recirculate wort through the HERMS coil. This will allow you to maintain a constant tem-

perature.

We recommend using a whirlpool in the HLT to improve heat transfer to the HERMS Coil. This will increase efficiency of your strike

temperatures. Review the charts below for heating data.

Using a Whirlpool in Your HLT-

• Reduces time to strike by ~30%

• Reduces HLT-MT Temp differential by a few degrees

Test results for a mash target strike temperature of 150°F and hot liquor set temperature of 155°F or 153°F when using whirlpool.

3

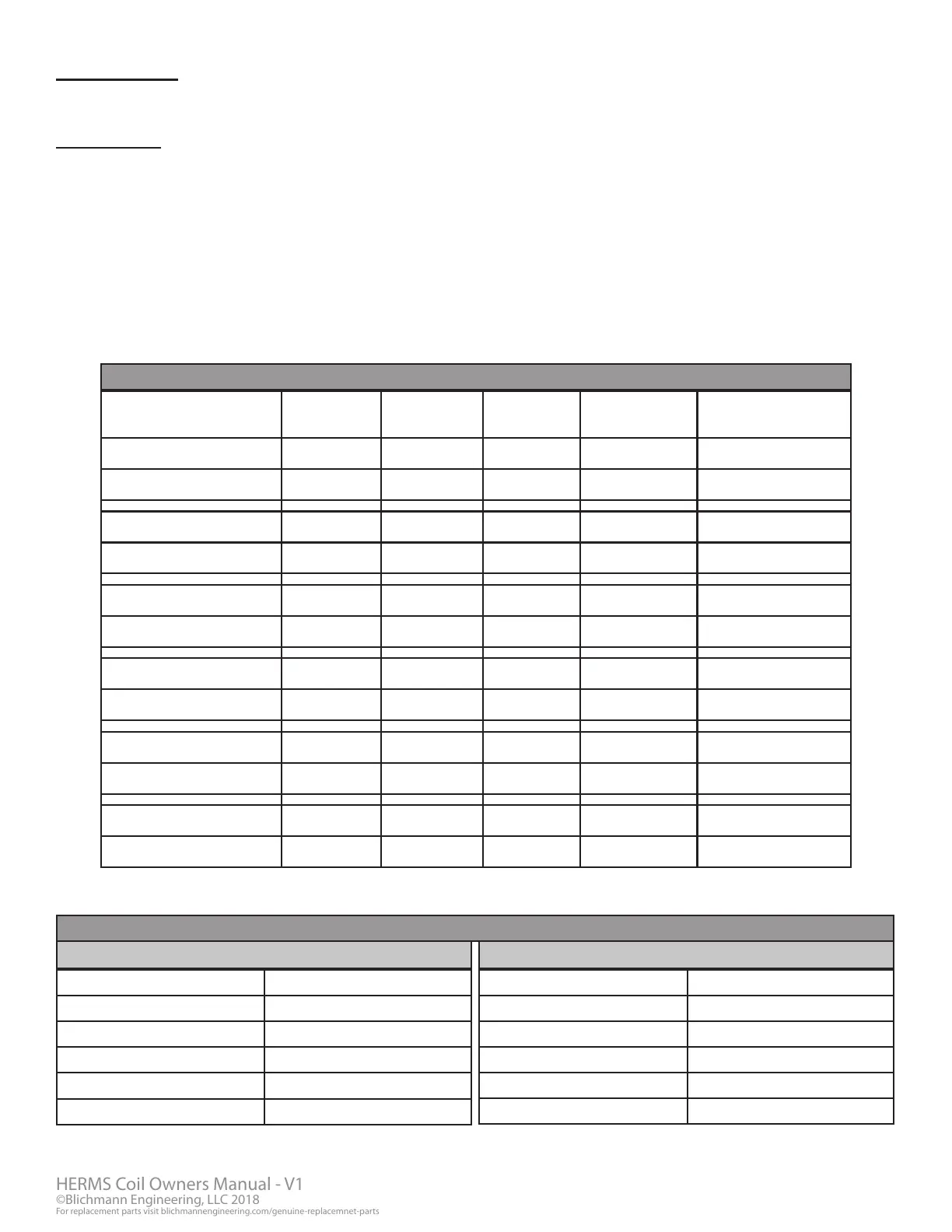

Flow Rate (gal/min) Pressure Drop (psi)

2.25 6.8

2 5.4

1.5 3.8

1 1.7

0.5 0.9

Large HERMS

Flow Rate (gal/min) Pressure Drop (psi)

2.5 6.4

2 4.5

1.5 2.9

1 1.5

0.5 0.9

Small HERMS

Large & Small HERMS Coil Flow Rate and Pressure Drop

Loading...

Loading...