7

TWO-STROKE OIL

● Never usetwo-strokeoilintended forwater-cooled

engines, sometimes referred to as outboard oil (rat-

edTCW).

● Neveruseoilintendedforfour-strokeengines.

MIXING RATIO

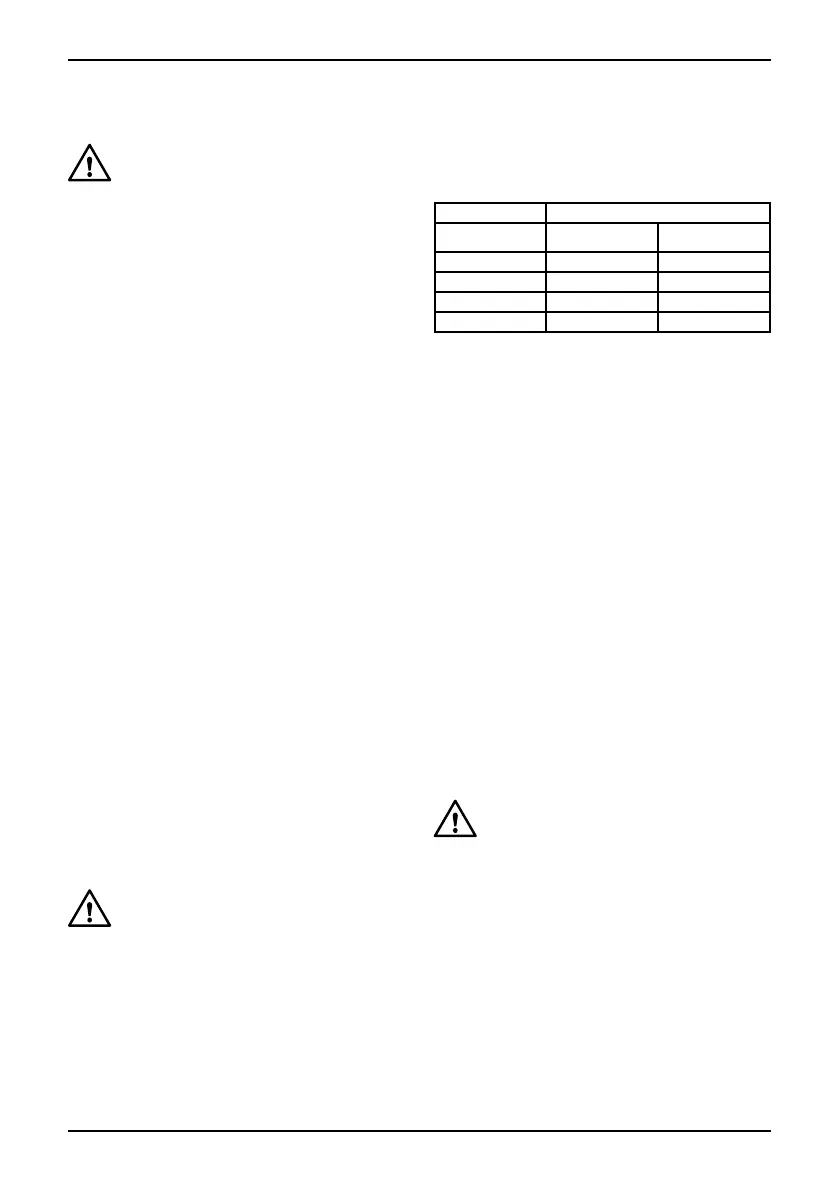

Petrol,litre Two-strokeoil,litre

2% (1:50) 3% (1:33)

5 0,10 0,15

10 0,20 0,30

15 0,30 0,45

20 0,40 0,60

MIXING

● Always mix the petrol and oil in a clean container

intended for fuel.

● Always startbylling halftheamount ofthepetrol

tobeused.Thenaddtheentireamountofoil.Mix

(shake) the fuel mixture. Add the remaining amount

of petrol.

● Mix(shake)thefuelmixturethoroughlybeforelling

the machine’s fuel tank.

● Donotmixmorethanonemonth’ssupplyoffuelat

a time.

● Ifthemachineisnotusedforsometimethefueltank

should be emptied and cleaned.

Chain oil

● Werecommendtheuseofspecialoil(chainoil)with

good adhesion characteristics.

● Neverusewasteoil.Thisresultsindamagetotheoil

pump, the bar and the chain.

● Itisimportanttouseoiloftherightgrade(suitable

viscosity range) to suit the air temperature.

● Intemperaturesbelow0°C(32°F)someoilsbecome

tooviscous.Thiscanoverloadtheoilpumpandre-

sult in damage to the oil pump components.

● Contactyourserviceagentwhenchoosingchainoil.

FUELLING

WARNING!Takingthefollowingprecautions,

willlessentheriskofre:Donotsmokeand

do not place any hot objects in the vicinity of

fuel. Always stop the engine and let it cool for a few

minutes before refuelling. When refuelling, open the

fuel cap slowly so that any excess pressure is released

gently.Tightenthefuelcapcarefullyafterrefuelling.

Always move the machine away from the refuelling

area before starting.

ASSEMBLY

FITTING THE BAR AND CHAIN

WARNING!Switchotheenginebeforecar-

rying out any checks or maintenance. The

stop switch automatically returns to the start

position. In order to prevent unintentional starting, the

spark plug cap must be removed from the spark plug

when assembling, checking and/or performing mainte-

nance.

Always wear gloves, when working with the chain, in

order to protect your hands from injury.

Check that the chain brake is in disengaged position by

moving the front hand guard towards the front handle.

Remove the bar nuts and remove the clutch cover

(chainbrake).Takeothetransportationring.

Fitthebaroverthebarbolts.Placethebarinitsrear-

mostposition.Placethechainoverthedrivesprocket

locate it in the groove on the bar. Begin on the top edge

of the bar.

Make sure that the edges of the cutting links are facing

forward on the top edge of the bar.

Fit the clutch cover (the chain brake) and locate the

chain adjuster pin in the hole in the bar. Check that

thedrive linksofthechaint correctlyover thedrive

sprocket and that the chain is correctly located in the

grooveinthebar.Tightenthebarnutsngertight.

Tensionthechainbyturningthechaintensioningscrew

clockwise using the combination spanner. The chain

should be tensioned until it does not sag from the un-

derside of the bar.

Thechainiscorrectlytensionedwhenitdoesnotsag

from the underside of the bar, but can still be turned

easilybyhand.Holdupthebartipandtightenthebar

nuts with the combination spanner.

Whenttinganewchain,thechaintensionhastobe

checked frequently until the chain is run-in. Check the

chain tension regularly. A correctly tensioned chain en-

sures good cutting performance and long life.

FUEL

Note!Themachine isequippedwith atwo-strokeen-

gine and must always be run using a mixture of petrol

and twostroke oil. It is important to accurately measure

the amount of oil to be mixed to ensure that the cor-

rect mixture is obtained. When mixing small amounts

of fuel,evensmall inaccuracies can drasticallyaect

the ratio of the mixture.

WARNING! Always ensure there is adequate

ventilation when handling fuel.

Petrol

● Usegoodqualityunleadedorleadedpetrol.

● Thelowestrecommendedoctanegradeis92.

● Whenworkingwithcontinuoushighrevs(e.g.limb-

ing) a higher octane is recommended.

Running-in

Avoid running at a too high speed for extended periods

duringtherst10hours.

Loading...

Loading...