18

Before operating, make sure

the entire unit (table with router

installed) is placed on and secured to a solid, flat,

level surface and will not tip. Use of auxiliary in-feed

and out-feed supports is necessary for long or wide

workpieces. Long workpieces without adequate

support can cause the router table to tip over.

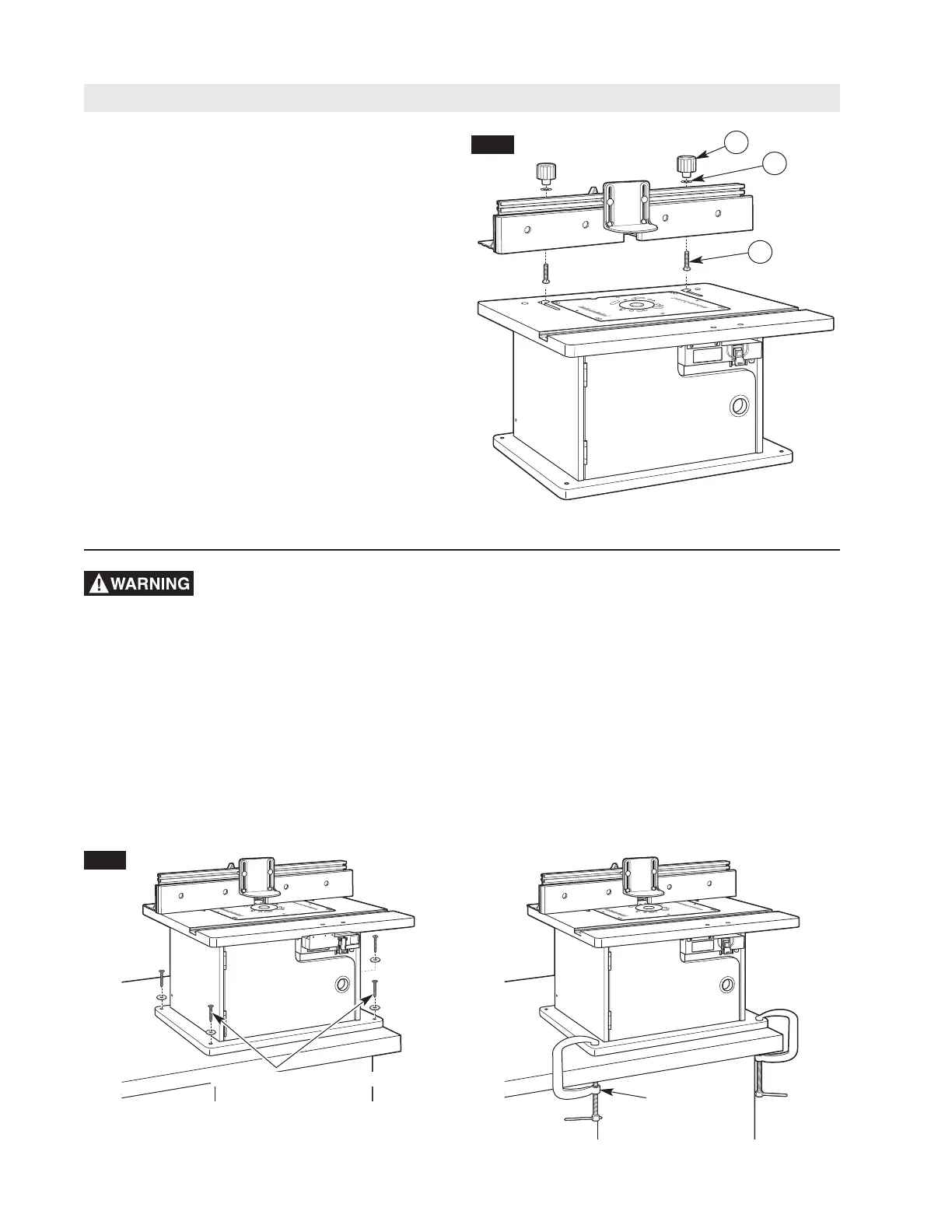

SECURING THE ROUTER TABLE TO A

WORK SURFACE (Fig. 15)

Preferred method:

The base of the router table has four mounting holes.

These holes can be used to attach it to a workbench

or work surface with four 1/4

″ wood screws and

washers or bolts, washers, and nuts (not provided).

1/4

″″

WOOD SCREWS OR BOLTS

C-CLAMPS

FIG. 15

OR

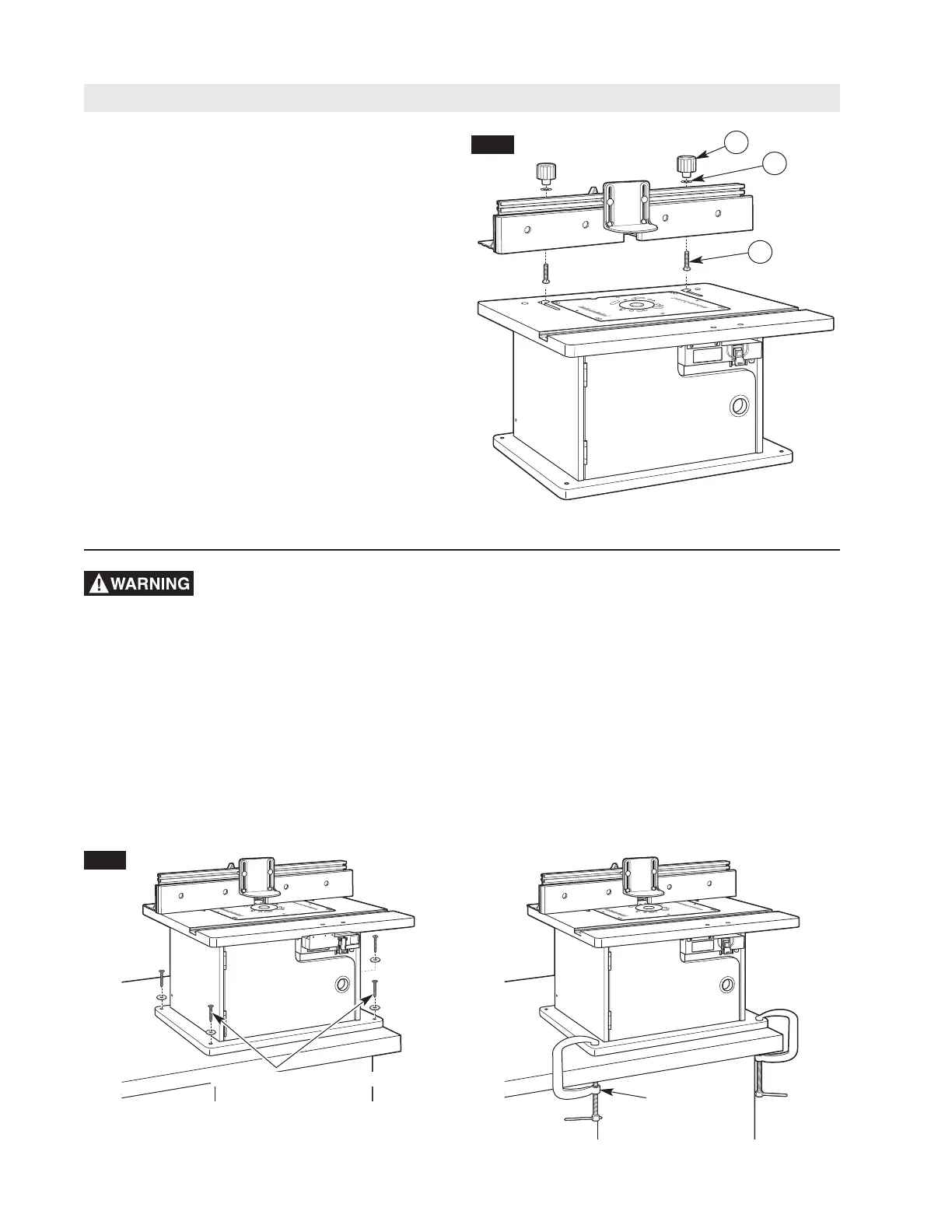

Router Table Assembly

ATTACHING THE FENCE TO THE TABLE

(Fig. 14)

1. From underneath, slide two 1/4-20 x 1

3

⁄4″ carriage

bolts (41) up through the holes in the bottom of the

fence. Slide a large washer (31) onto each bolt and

l

oosely attach a large clamping knob (19) onto

each bolt.

2. Insert the carriage bolt heads through the holes of

the J-slots on the tabletop, making sure the bolt

head is below the inside surface of the tabletop and

can slide freely into the J-slot.

3. Slide the fence assembly left and into the J-slot and

make sure that it slides smoothly from front to back.

NOTE: Use the scale on the tabletop as a guide

when aligning the fence for routing operations. Once

the fence is positioned and aligned correctly, tighten

the clamping knobs SECURELY.

19

FIG. 14

31

HINT: Position the router table in the desired location

and mark the hole locations using the holes in the table

base. Then drill suitable pilot (for wood screws) or

through-holes (for bolts).

Alternative method:

The base can be secured to a workbench or work

surface with C-clamps.

41

Loading...

Loading...