8 | English

1 609 92A 47U | (28.02.2018) Robert Bosch Power Tools GmbH

Technical data

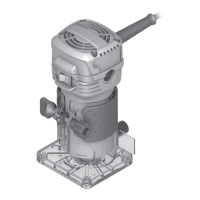

Router GKF 550

Article number

3 601 FA0 0..

Rated power input W 550

No-load speed rpm 33,000

Tool holder mm

inches

6

¼

Weight according to EPTA Pro-

cedure 01:2014

kg 1.4

Protection class / II

The specifications apply to a rated voltage [U] of 230 V. These spe-

cifications may vary at different voltages and in country-specific mod-

els.

Fitting

Changing the tool

u Pull the plug out of the socket before carrying out any

work on the power tool.

u Wearing protective gloves while fitting and changing

router bits is recommended.

Removing the routing base (see figure A)

Before fitting a router bit, you must first separate the routing

base(2) from the drive unit(1).

Open the wing bolt (11) on the routing base (2).

Pull the drive unit out in an upward direction.

Changing the collet (see figure B)

Depending on the router bit used, you may have to change

the tightening nut with the collet(14) before fitting the

router bit.

If the correct collet for your router bit is already fitted,

please follow the work steps in the following section on (see

"Fitting the router bit (see figure C1 – C2)", page8).

The collet(14) must sit in the tightening nut with a small

amount of play. The tightening nut(7) must be easy to fit. If

the tightening nut or collet is damaged, replace it immedi-

ately.

Place the open-end spanner(16) on the tool holder(15)

(see figureC1).

Unscrew the tightening nut(7) in an anti-clockwise direction

using the open-end spanner(17).

If required, clean all the parts you want to fit with a soft

brush or by blowing them clean with compressed air before

assembling them.

Place the new tightening nut onto the tool holder(15).

Loosely tighten the tightening nut.

u Do not, under any circumstances, tighten the collet

with the tightening nut until a router bit has been fit-

ted. The collet may otherwise become damaged.

Fitting the router bit (see figure C1 – C2)

Router bits are available in a wide variety of designs and

qualities depending on the intended application.

Router bits made of high-performance high-speed steel

(HSS) are suited to machining soft materials such as soft-

wood and plastic.

Router bits with carbide tips are especially suitable for

hard and abrasive materials such as hardwood and alu-

minium.

Original router bits from the extensive range of Bosch ac-

cessories are available from your specialist dealer.

Only use undamaged and clean router bits.

Fitting the routing base (see figure A)

To start routing, the routing base(2) must be fitted back

onto the drive unit(1).

Open the wing bolt(11) on the routing base(2).

Slide the drive unit(1) into the routing base(2).

Close the wing bolt(11) on the routing base(2).

u After assembly, always check that the drive unit is

firmly seated in the routing base.

Dust/Chip Extraction

Dust from materials such as lead-containing coatings, some

wood types, minerals and metal can be harmful to one’s

health. Touching or breathing-in the dust can cause allergic

reactions and/or lead to respiratory infections of the user or

bystanders.

Certain dust, such as oak or beech dust, is considered carci-

nogenic, especially in connection with wood-treatment ad-

ditives (chromate, wood preservative). Materials containing

asbestos may only be worked by specialists.

– Provide for good ventilation of the working place.

– It is recommended to wear a P2 filter-class respirator.

Observe the relevant regulations in your country for the ma-

terials to be worked.

u Avoid dust accumulation at the workplace. Dust can

easily ignite.

Operation

u Products that are only sold in AUS and NZ: Use a resid-

ual current device (RCD) with a nominal residual current

of 30 mA or less.

Setting the routing depth

u The routing depth must only be set while the power

tool is switched off.

To set the rough routing depth, proceed as follows:

– Place the power tool with a fitted router bit onto the work-

piece you want to machine.

– Open the wing bolt(11) on the routing base(2).

– Move the drive unit(1) to the desired depth using the

scale for setting the routing depth(13) as a guide.

– Close the wing bolt(11) on the routing base(2).

– Check the routing depth you have set by carrying out a

practical test and correct it if required.

Loading...

Loading...