The provided document is an owner's manual for the BOSS SNOWPLOW VBX 3000 V-Box Spreader. This device is designed for spreading materials like dry, free-flowing salt or cinder/salt mixes.

Function Description:

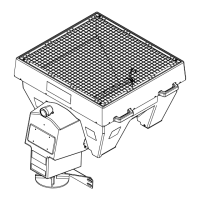

The BOSS VBX 3000 V-Box Spreader is a vehicle-mounted unit used for distributing de-icing materials. It features a V-box hopper design, an auger-based feeder system, and a spinner assembly to broadcast the material. The spreader is controlled by an in-cab controller that allows the operator to adjust various parameters, including feeder speed, spinner speed, and activate a vibrator or "blast" function. The material deflectors are adjustable to customize the spread pattern. The unit is designed for installation in the bed of a utility vehicle, requiring secure mounting with ratchet straps and tie-down D-rings.

Important Technical Specifications:

- Part Numbers: VBS11060 and VBS19300B (for serial numbers 400000000 and Up).

- Minimum Truck Bed Length: 85 cm (33-1/2 inches).

- Dimensions:

- Length: 132 cm (52 inches)

- Hopper height: 71 cm (28 inches)

- Hopper width: 127 cm (50 inches)

- Weight (empty): 104 kg (230 lb).

- Capacity: 0.34 m³ (12 ft³).

- Material Compatibility: Dry, free-flowing salt or cinder/salt mixes only.

- Maximum Operating Speed: Do not exceed 22 km/h (14 mph) while spreading.

- Sound Level: Below 70 dBA inside the vehicle during operation.

- Electrical System: Requires connection to the vehicle's battery (positive and negative terminals) and an ignition switch power source. Includes a spade connector and ground cable.

- D-Ring Torque: Bolts for D-rings should be torqued to 28 Nm (19.7 ft-lb).

Usage Features:

- Controller: An in-cab controller (MSC06370) with a display and dials for adjusting feeder and spinner speeds. It includes indicator LEDs for power, light, vibrator, and blast functions.

- Feed Speed Dial: Increases/decreases feeder motor speed.

- Feed Speed Display: Shows current feeder motor speed.

- Spinner Speed Dial: Increases/decreases spinner motor speed.

- Spinner Speed Display: Shows current spinner motor speed.

- Power Button: Turns the controller and motors on/off. Holding for 3 seconds turns off motors and controller.

- Light Button: Turns the rear light on/off.

- Vibrator Button: Switches the vibrator on/off when the feeder motor is on.

- Blast Button: Momentarily sends full power to the spinner and feeder motors for quick material discharge.

- Power LED: Green when on/motors running, amber when clearing, flashing red for jam/disconnection.

- Adjustable Material Deflectors: Pins can be inserted into staggered holes around the spinner to adjust the spread pattern (driver side open, passenger side open, or both sides open).

- Adjustable Baffle: The baffle inside the hopper can be raised or lowered to increase or decrease the flow rate and load on the feeder.

- Loading: Materials should be filled evenly and not past the top of the hopper. Operators must consider the vehicle's Gross Vehicle Weight Rating (GVWR) and Gross Axle Weight Ratings (GAWR).

- Unloading: The spreader can be unloaded by removing the spinner assembly and turning the Feed Speed dial to 9.

- Clog Management: The controller provides visual alerts (flashing LEDs) for clogs. If not cleared automatically, the spreader wire harness should be disconnected, and the clog manually freed.

- Safety Decals: Multiple decals (MSC19399, VBS14567, MSC19312) are present on the machine, indicating warnings for reading the manual, training, tipping hazards, overloaded hopper, raising vehicle bed, unsecured ratchet straps, cutting/dismemberment, and entanglement.

Maintenance Features:

- Recommended Maintenance Schedule:

- Before each use or daily: Check and tighten ratchet straps.

- Every 20 hours: Clean the chute of any buildup, grease the bearings, tighten hardware.

- Before storage: Unload the spreader, clean and grease all bearings.

- Lubrication: Grease all bearings with a No. 2 lithium grease every 20 hours.

- Storage:

- Unload all material from the hopper.

- Remove the spreader from the vehicle.

- Wash and rinse the entire machine.

- Clean and grease all bearings.

- Clean all exposed connectors and apply dielectric grease.

- Remove the controller from the vehicle and store it in a clean, dry place.

- Troubleshooting Guide: The manual includes a comprehensive troubleshooting table for common issues like no power, motor not working, flashing LEDs (indicating jams or disconnections), and light/vibrator malfunctions, along with possible causes and corrective actions.

- Component Removal for Maintenance: Instructions are provided for removing the spinner assembly and adjusting the baffle, which may be necessary for cleaning or maintenance.

The BOSS VBX 3000 V-Box Spreader is designed for efficient and controlled spreading of de-icing materials, emphasizing user safety through clear instructions and warnings, and promoting longevity through a detailed maintenance schedule.