When tting the cooler into the pipe work, care must be taken to ensure that

no debris has been introduced into the primary or secondary circuits.

Unsupported lengths of pipework should be avoided so as not to subject the

cooler to excessive loads.

Water side pipework diameter should not reduce to less than the connection

size within a distance of 1m from the cooler.

Measures should be taken to isolate the cooler from excessive vibration. Water

pipe connections are parallel thread. Taper pipe ttings are not recommended

as they can split the end cover if over tightened.

The charge air inlet and outlet are designed to have hose connections using

hose clamps apart from the PK and RK cooler sizes which have ange

connection faces.

Please ensure that the connection ow area is maintained into the cooler and

avoid tight bends to prevent excessive pressure loss.

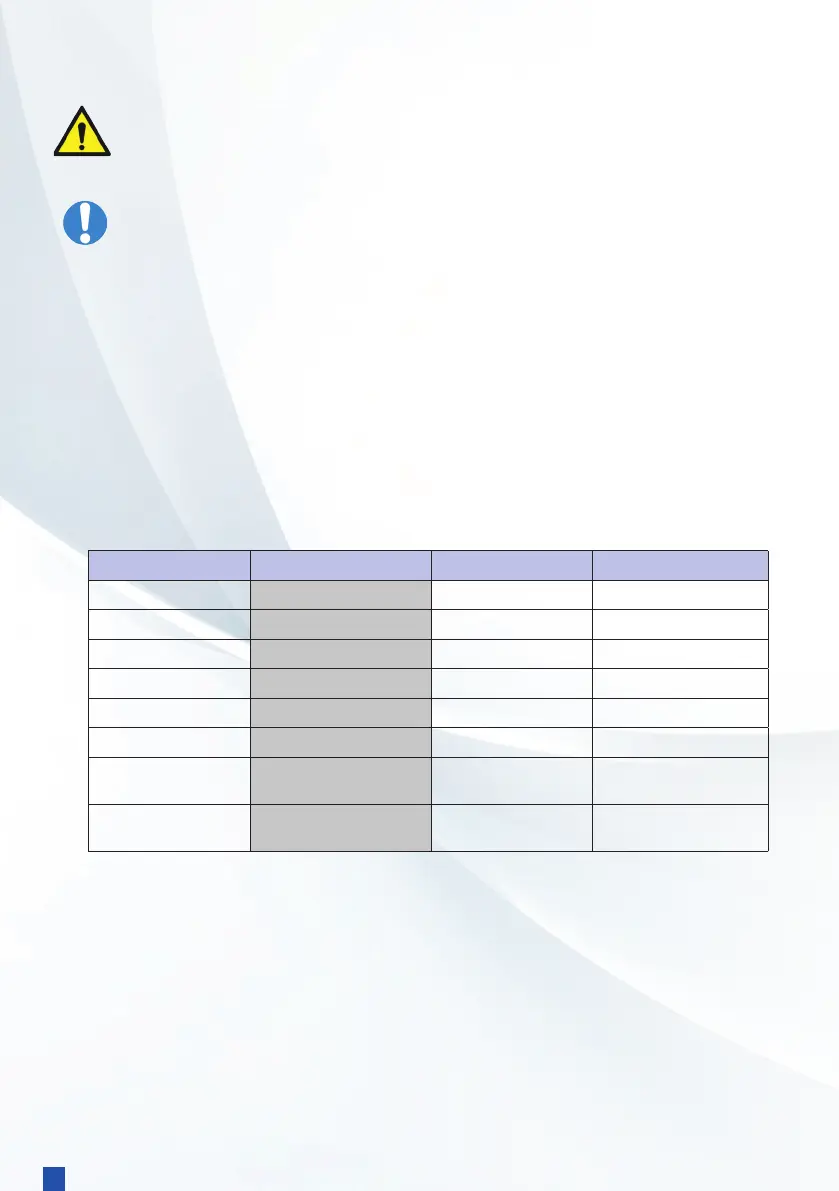

Type Connection Type

Size Water Connections

EC120 Hose

52 mm ¾” BSP

FC100 Hose

52 mm 1” BSP

FG100 Hose

76 mm 1¼” BSP

GL140 Hose

76 mm 1½” BSP

GK190 Hose

89 mm 2” BSP

JK190 Hose

102 mm 2½” BSP

PK250 PN6 Flange

4 x M16 x 32mm on a

170mm PCD

3” BSP

RK250 Flange

4 x M16 x 32mm on a

212mm PCD

8 x 18mm on a 180mm

PCD (PN6-DN100)

Pipework materials must be compatible with the cooler materials.

Stainless steel sea water pipes and ttings should not be used adjacent

to the cooler.

2.3 Connecting the cooler

Take Care

2

6

Loading...

Loading...