2/5 2704_r03

DIRECTIONS FOR INSTALLATION AND MAINTENANCE

• This valve is a safety appliance and should not be

modified. The manufacturer's responsibility and guarantee

are invalidated in case the device is tampered with by the

user.

• The applicable national regulation and European

standards (Ex. EN 60335-1 and EN 60335-2-102) related

to the electrical safety must be respected;

• Assemble the valve to the installation so that the arrow

on the valve body has the same direction as the fuel flow.

• During the assembly of the valve to the installation

piping, avoid twisting on the sheath and always use an

hexagonal wrench to be fitted to the valve body.

• Make sure that no foreign matters have entered the

valve body.

• Make sure that the max. fuel input pressure never

exceeds the value appearing on the label.

• All operations (installation, maintenance, etc.) must be

carried out by a qualified technician.

• Before any connection operation, completely isolate the

system from power supply (multi-pole disconnection).

Place the system safely to avoid accidental switch-on and

make sure there is no voltage. If the system is not

switched off, there is a risk of electric shock.

• During and after any operation (installation,

maintenance, etc.), make sure that the type and code are

the ones provided, check the correct functioning and the

internal and external thickness of the valve.

• In the event of a fall or impact, the valves must not be

started, as safety functions may be compromised even if

no damage is visible to the outside.

• Faulty valves or damaged must be unplugged from power

supply and cannot be used.

• The valve has a designed lifetime* based on the

endurance tests in the standard EN 161. A summary of

the conditions has been published by the European

Control Manufacturers Association (Afecor)

(www.afecor.org). The designed lifetime is based on use

of the valve according to the manufacturer’s technical

notes. After reaching the designed lifetime in terms of the

number of burner startup cycles, or the respective time of

usage, the valve has to be replaced by authorized

personnel.

* The designed lifetime is not the warranty time specified

in the Terms of Delivery

DIRECTIONS FOR EG12*L... VALVES ADJUSTMENT

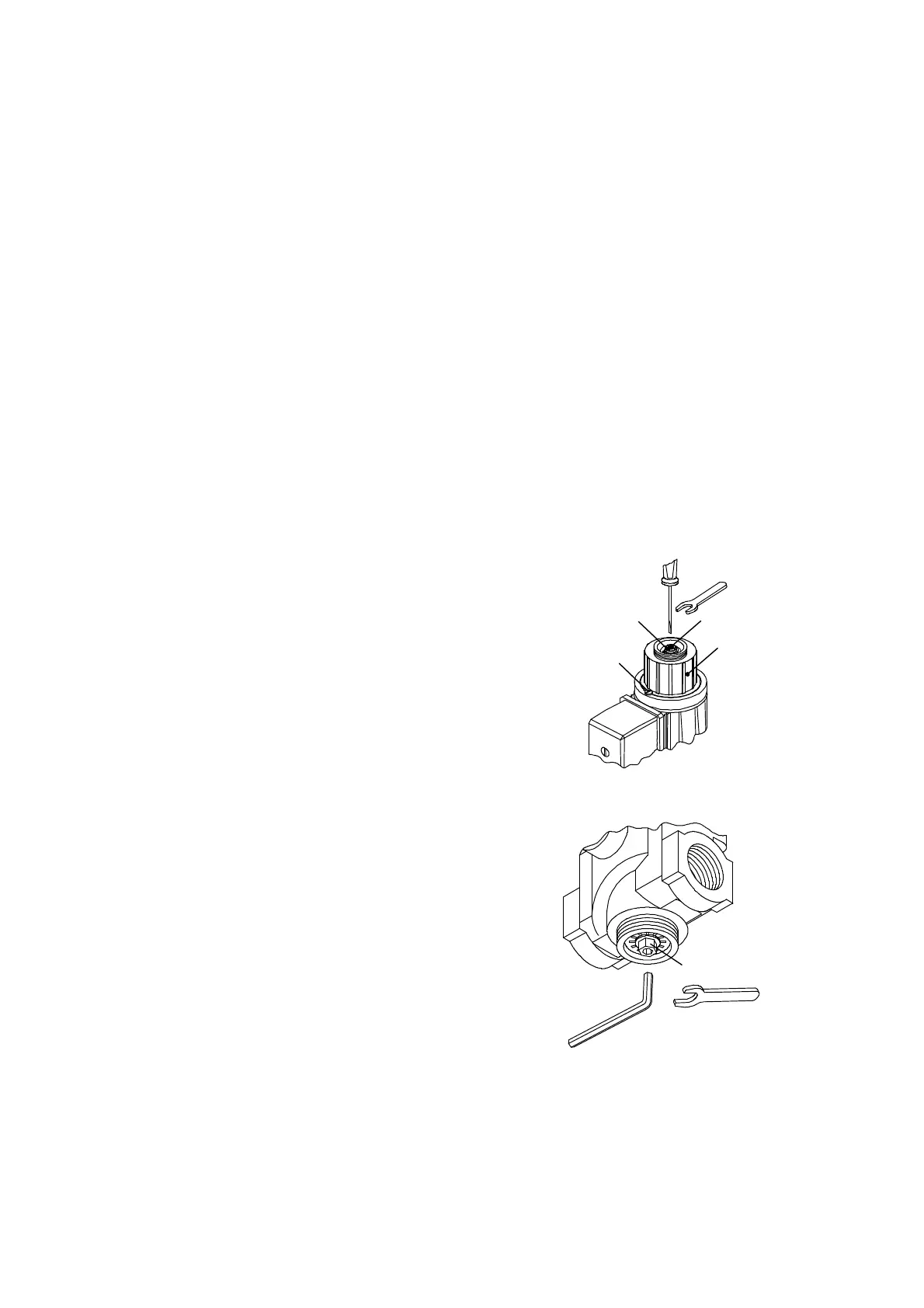

Flow adjustment for EG12*L...

To adjust the gas flow, you have to remove one of the two

screws used to fasten the lag group (the not enamelled one,

marked with 4 in Fig.1) and rotate clockwise the whole group

to reduce the flow or in the opposite direction to increase it.

Opening time adjustment

After removing the top protection, by rotating it

counterclockwise, you have to act on the adjustment screw,

marked with 1 in Fig.1; by rotating clockwise, the opening

time becomes longer, by rotating in the opposite direction, the

opening time becomes shorter.

Quick release initial flow adjustment

After removing the top protection by rotating it

counterclockwise, if you rotate clockwise the nut marked with

2 in Fig.1, the initial release will be reduced; if you rotate the

same nut counterclockwise, the initial release will be

increased.

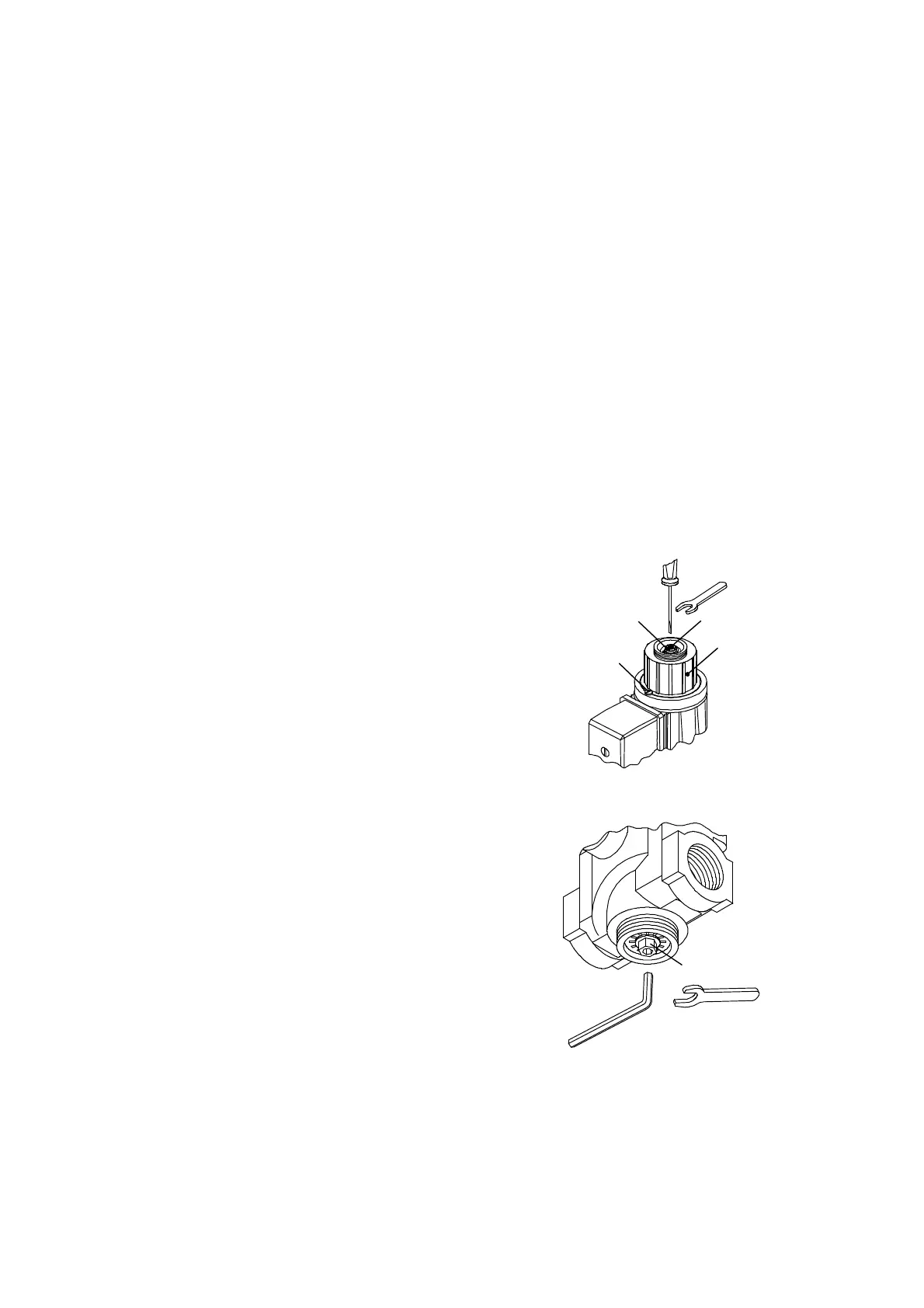

DIRECTIONS FOR EG12*SR... AND EG12*AR... VALVES

ADJUSTMENT

Flow adjustment for EG12*R

After removing the bottom protection by rotating it

counterclockwise, rotate clockwise the nut marked with 1 in

Fig.2 to reduce the flow, rotate in the opposite direction to

increase the same.

2 1

3

4

Fig. 1

1

Fig. 2

Loading...

Loading...