Do you have a question about the Briggs & Stratton 750 DOV Series and is the answer not in the manual?

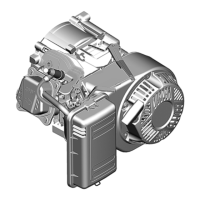

| Brand | Briggs & Stratton |

|---|---|

| Model | 750 DOV Series |

| Category | Engine |

| Language | English |

Provides essential safety guidelines for engine operation and maintenance.

Covers fuel/oil recommendations and a detailed maintenance schedule.

Systematic approach to diagnosing common engine operational problems.

Procedures for testing alternators, starters, and batteries.

Instructions for removing, inspecting, and installing the muffler and guard.

Procedure for fuel tank removal, inspection, and installation.

Steps for carburetor removal, disassembly, inspection, and assembly.

Notes on observing linkage and spring placement before governor disassembly.

Procedure for checking and adjusting engine maximum RPM under no load.

Details on disassembling, inspecting, and assembling governor components.

Step-by-step guide to removing and reinstalling the cylinder head.

Guidance on inspecting cylinder head and valves for damage or wear.

Instructions for taking apart and reassembling cylinder head components.

Procedures for checking, disassembling, and assembling the electric starter.

Step-by-step guide for replacing the starter rope and handle.

Details on the plastic oil fill tube and quarter-turn dipstick assembly.

Instructions for removing, checking, and installing the breather system.

Guidance on inspecting the governor gear/oil slinger for wear or damage.

Procedure for checking cylinder for damage, distortion, and bore reconditioning.

Checks for cracks, threads, wear, and cleaning procedures for the sump.

Procedure for pressing in new oil seals for the cylinder and sump.

Steps for removing and inspecting the crankshaft for scoring and wear.

Procedure for installing the crankshaft and adjusting end play.

Instructions for installing the sump onto the cylinder with new gaskets.

Steps for removing piston, connecting rod, and associated components.

Checking piston, rings, and pin for wear, damage, and proper clearance.

Inspection of connecting rod bearings for scoring or discoloration.

Steps for assembling piston, rings, and connecting rod components.

Procedure for installing the piston and connecting rod assembly into cylinder.

Engine and fastener torque specifications for Model 090600.

Engine and fastener torque specifications for Model 100600.

Engine and fastener torque specifications for Model 100800.

Loading...

Loading...