UNDERWATER OPERATIONS CONT.

Note: Broco Underwater Ultrathermic cutting rods will continue to burn as long

as the oxygen flow is maintained, even with the power off. The oxygen lever

must be released to extinguish the cutting rod.

1. Ensure the safety knife switch is in the open position and the welding ma-

chine is turned off prior to securing the ground clamp to the workpiece as

close to the area to be cut as possible. Ensure the ground clamp is away

from the diver as he proceeds to cut.

2. Check that the oxygen delivery pressure is correctly set by squeezing the

torch lever to release a stream of oxygen. A 6” jet of oxygen should issue

from the cutting rod tip.

3. Loosen the torch collet nut 1/2 turn.

4. Insert the end of the Broco Underwater Ultrathermic cutting rod that has the

recessed internal wires into the collet opening until it bottoms on the collet

washer.

5. Tighten the collet nut to lock the rod in place.

6. Check for oxygen leaks at the collet nut and around the collet by squeezing

the oxygen lever. If a leak exists: make sure the rod is firmly seated on the

collet washer; inspect the rod for damage; inspect the collet washer for

damage and replace if necessary.

7. Place the tip of the rod against the work at the point where the cut is to be

initiated and squeeze the oxygen lever for four seconds to purge the rod

and torch.

8. With the oxygen still flowing call for the current to be switched on. The ten-

der will close the safety knife switch.

9. Draw the tip of the cutting rod across the work to strike the arc.

10.

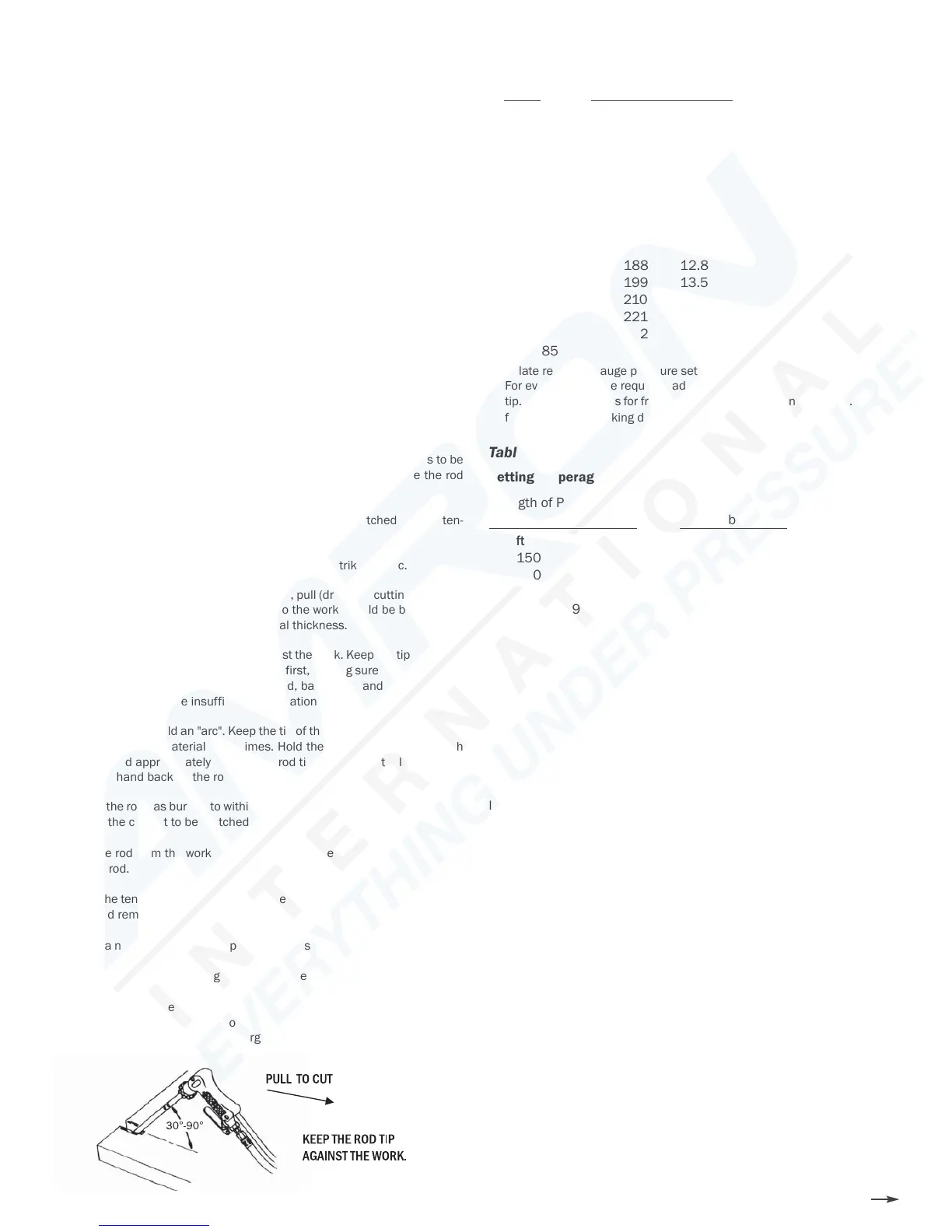

Once the arc is struck and the rod ignited, pull (drag) the cutting rod along

the line to be cut. The angle of the rod to the work should be between 30

and 90 degrees, depending on the metal thickness.

11.

Maintain pressure to keep the rod against the work. Keep the tip of the rod

in the puddle at all times. Move slowly at first, making sure full penetration

is achieved. As cutting speed is increased, back spray and increased cut-

ting noise will indicate insufficient penetration.

Note: Do not try to hold an "arc". Keep the tip of the burning rod in direct con-

tact with the target material at all times. Hold the rod "like a pool cue" with

your free hand approximately 4" from the rod tip for a more stable cut. Keep

moving the hand back as the rod consumes.

12.

When the rod has burned to within approximately 3" of the torch collet nut

call for the current to be switched off.

13.

Lift the rod from the work and release the oxygen lever to extinguish the

cutting rod.

14.

After the tender has confirmed the current is off, loosen the collet nut 1/2

turn and remove rod stub from the torch.

15.

Insert a new cutting rod and repeat the process until the cut is complete.

Note: When cutting or melting non-conductive materials such as concrete,

rock, coral, mastic, rope or marine growth, a striker plate (consisting of a steel

or copper plate connected to the ground cable) is necessary to initiate the

arc and light the rod. Once the rod is ignited, maintain the oxygen flow and

bring the rod into contact with the target material.

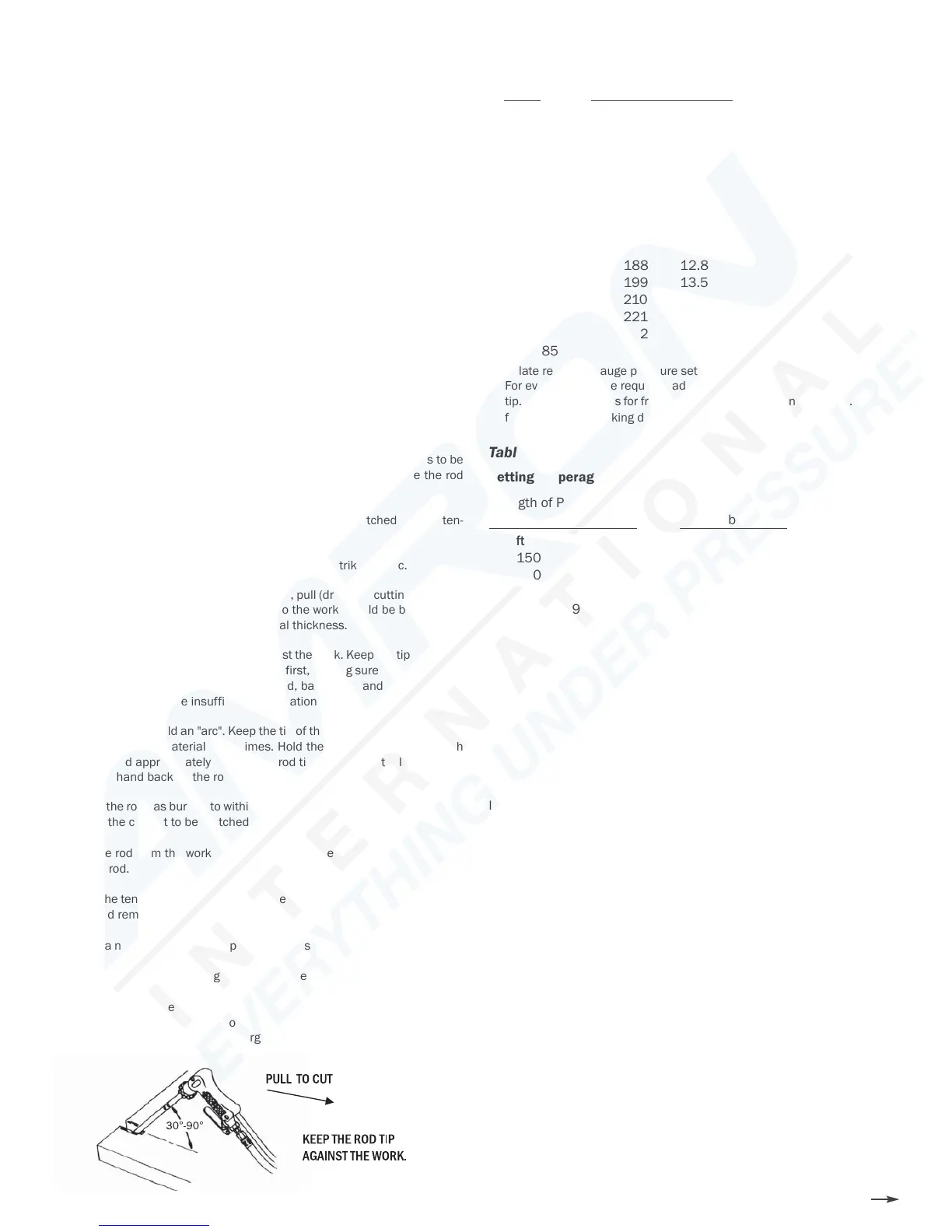

Table #1

Setting Oxygen Delivery Pressure for Depth

Depth

Pressure Gauge Setting

ft m psig kpa

33 10 108 7.4

40 12 112 7.6

60 18 123 8.4

80 24 134 9.1

100 30 145 9.9

120 37 155 10.5

140 43 166 11.3

160 49 177 12.0

180 55 188 12.8

200 61 199 13.5

220 67 210 14.3

240 73 221 15.0

260 79 232 15.8

280 85 243 16.5

Calculate regulator gauge pressure setting as follows:

For every 10' of hose required, add 1 psig to the 90 psig necessary at the

tip. This compensates for frictional line losses. Additionally, add 0.445 psig

for every foot of working depth.

Table #2

Setting Amperage for Cable Length and Size*

Length of Power Cable Amperage setting

(supply to work distance) for Cable Size

ft m # 1/0 #2/0 #3/0

150 46 155 152 150

200 61 157 154 152

250 76 159 156 154

300 91 161 158 156

350 107 163 160 158

400 122 165 162 160

450 137 167 164 162

500 152 169 166 164

*The increases in amperage compensate for resistance losses. For greater

lead lengths, add 2 amperes per fifty feet to settings.

TROUBLESHOOTING

Broco Underwater Ultrathermic cutting rods are different from steel tubu-

lar cutting rods in that Broco Underwater Ultrathermic cutting rods require

higher oxygen flow and lower amperage. Additionally Broco Underwater

Ultrathermic cutting rods require direct contact with the work, not main-

tenance of an arc. Most operational problems stem from operators using

steel tubular cutting rods' setup and cutting techniques.

Oxygen supply problems:

1. Efficient cutting with Broco Underwater Ultrathermic cutting rods relies

on high volume unobstructed oxygen flow. With inadequate oxygen

flow, the rod can burn without significantly affecting the work.

Symptoms include: the rod burning longer than 60 seconds of contin-

uous use; cuts of less than 12" in 1/2" thick steel plate; and an oxygen

jet of less than 6" length underwater.

Solutions:

A. Ensure that a high volume two-stage oxygen regulator and 3/8" oxy-

gen hose are being used.

B. Ensure that the hose is not kinked, pinched or obstructed.

C. Ensure that the oxygen cylinder valve (valves if using a manifold sys-

tem) are fully opened.

. . .continued

Loading...

Loading...