Bronkhorst®

Instruction Manual Controlled Evaporator and Mixer9.17.126A 15

3

Operation

In systems for use with corrosive, reactive or explosive media, purging the fluidic system for at least 30 minutes with a dry,

inert gas (like Nitrogen or Argon) is absolutely necessary before use. After use with such media, complete purging is also

required before exposing the system to air.

See section Purging for general purging instructions.

After correct installation and taking all necessary safety precautions, the CEM is ready to be used.

3.1 Powering up

· It is recommended to turn on power before applying pressure and to switch off power after removing pressure

· Follow the guidelines in the manuals for the flow meters/controllers with regard to warming up

When applying pressure, avoid pressure shocks and bring the fluidic system gradually up to the level of operating

conditions; open and close the fluid supply gently.

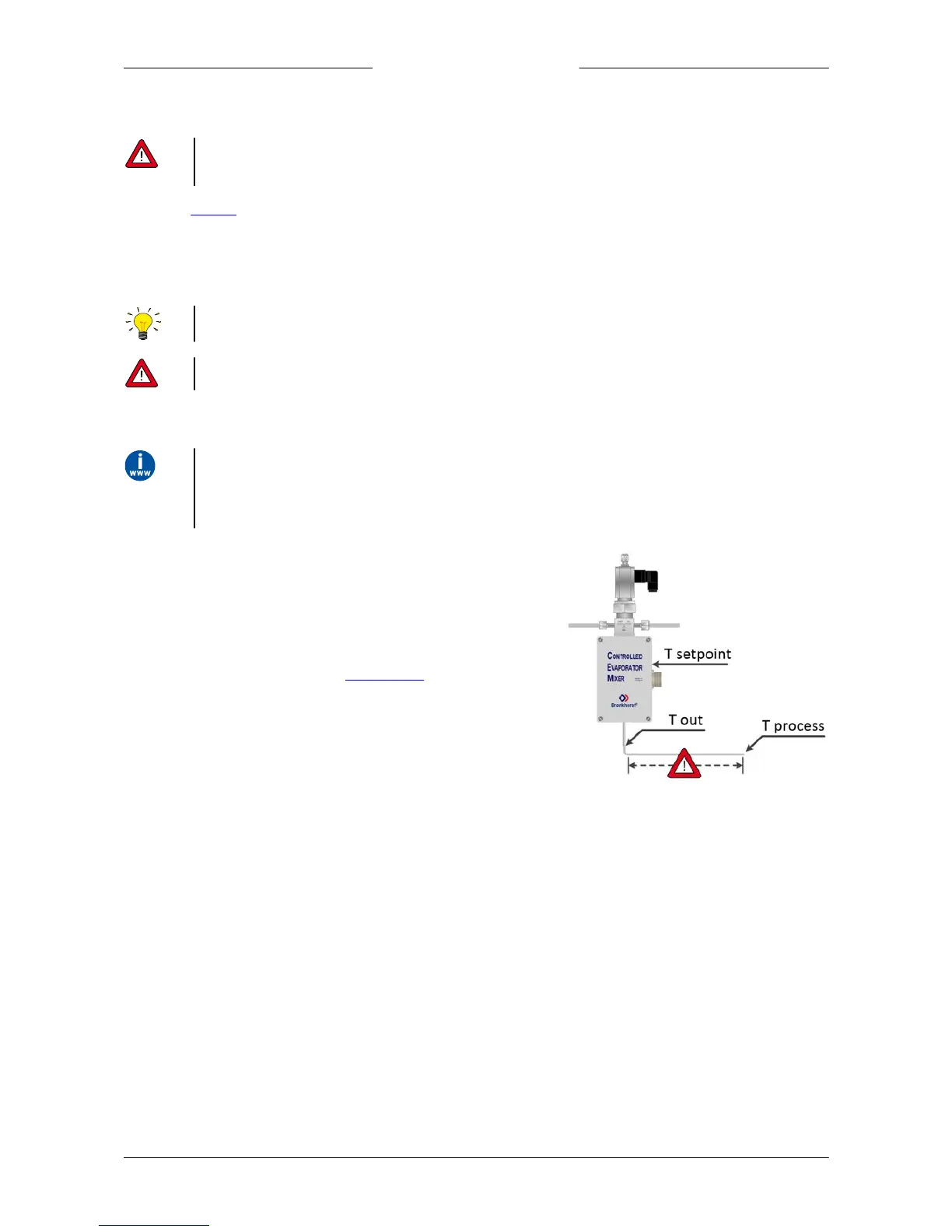

The required setpoints for the carrier gas and liquid flows and the temperature of the heat exchanger can be obtained from

FLUIDAT® on the Net, using the flow rates of the ordered instruments.

FLUIDAT® on the Net can be accessed via http://www.fluidat.com. Free registration on the FLUIDAT® website gives

access to all available fluids and functionality.

Basically, the temperature setpoint that FLUIDAT® calculates for the CEM

ensures that the heater will evaporate the liquid and that the vapour

temperature at the outlet will still be high enough to prevent condensation.

As a result, the required temperature setpoint will almost always be higher

than the required vapour temperature.

Further down the line, however, tubing length, process and ambient

conditions can cause the vapour temperature to drop to a point where

condensation might occur. See section Assembly tips how to prevent this.

Loading...

Loading...