28

5.3 CHIMNEY

The chimney is very important for the proper operation of the stove and it has two functions:

• Evacuate the smoke and the gas safely out of the house.

• Provide a draft enough to the stove or insert.

The draft also affects the intensity of the combustion and the heating performance of your equipment. A good draft of the fireplace needs a

reduced regulation of the air for the combustion, while a lack of draft needs a good regulation of the air for the combustion.

Therefore, it is essential that it is made perfectly and that it is subjected to maintenance operations in order to keep it in good conditions.

(Many of the claims due to malfunctioning reasons refer exclusively to a bad draft).

It is necessary to comply with the following requirements for the proper operation of the stove:

• The interior section must be preferably circular.

• It must be thermally insulated along its entire length in order to prevent condensation (the smoke is liquefied by heat shock) and even

more if the installation is outside the house.

• If we use metallic pipe for the installation outside the house, it is compulsory to use thermal insulated pipe. It consist of two concentric

pipes and, between them, there is a thermal insulator. Moreover, we will avoid condensation problems.

• It should not have bottlenecks (enlargements or reductions) and it must be vertical with deviations not higher that 45º.

• If it has been used previously, it must be clean.

• Respect the technical data of the instructions manual.

The optimum draft varies between 10 and 14 (Pascal). The measuring must be always made with the equipment hot (nominal heating power).

A lower value causes a bad combustion causing carbonic deposits and excessive smoke generation, having leaks and, even worse, an

increase of the temperature that could damage the structural components of the stove. When pressure exceeds 15 Pa it will be necessary

reduce it by installing an additional draft

regulator.

To check if the combustion is correct,

control if the smoke out the chimney is

transparent. If the smoke is white it means

that the equipment is not properly regulated

or the used pellet that is being used is

too wet. However, if the smoke is grey or

black it means that the combustion is not

completed (it is necessary a greater amount

of secondary air).

The connection of the stove must be done

with rigid aluminized steel pipes or stainless steel pipes. It is forbidden to

use flexible metallic pipes or fibre cement pipes because they damage

the safety of the connection as they are subject to jerks and breaks, which

causes smoke looses.

Materials that are prohibited for the chimney and, therefore, damage

the proper functioning of the equipment are: fibre cement, galvanized

steel and rough and porous interior surfaces. An example of solution is

described below:

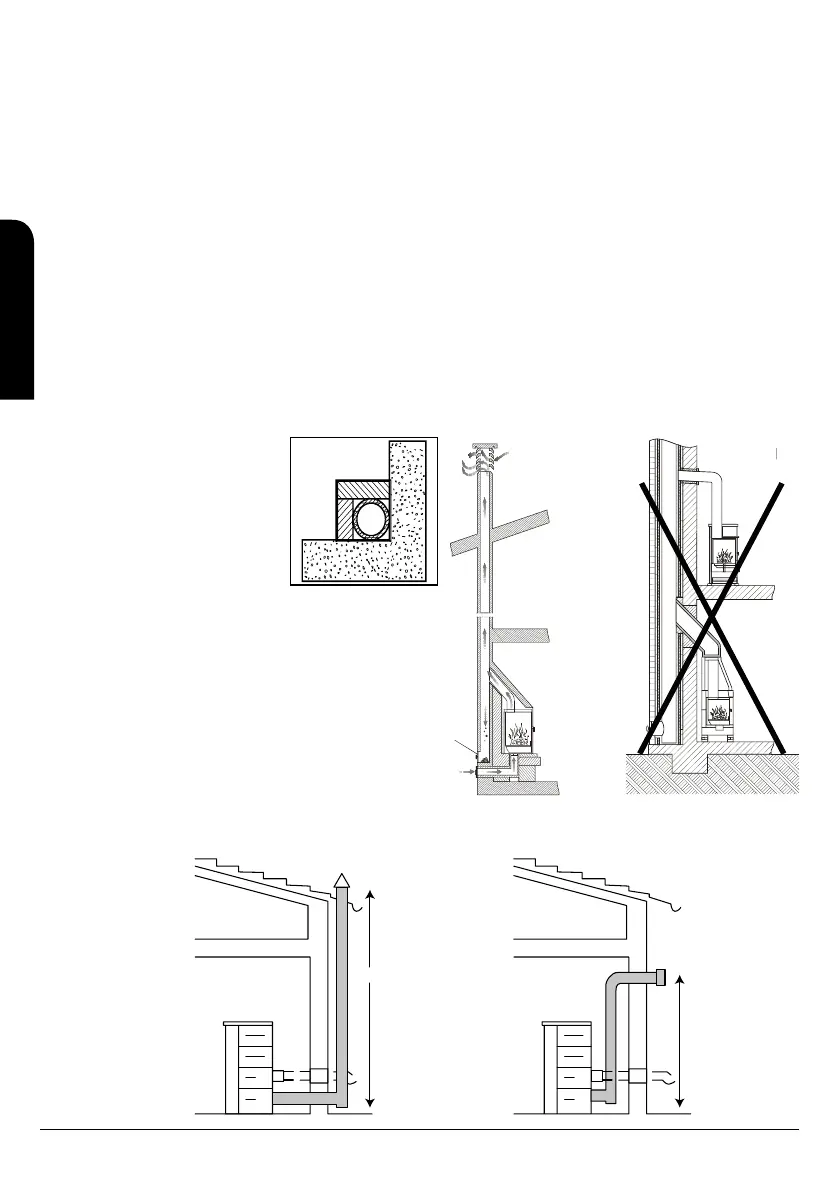

(1) Stainless steel AISI 316 chimney with double insulated chamber and

material resistant up to 400°C. Efficiency 100% optimum (see drawing

D9).

All stoves that send smoke to the exterior should have their own chimney.

Never use the same chimney for several equipments at the same time

(see drawing D10).

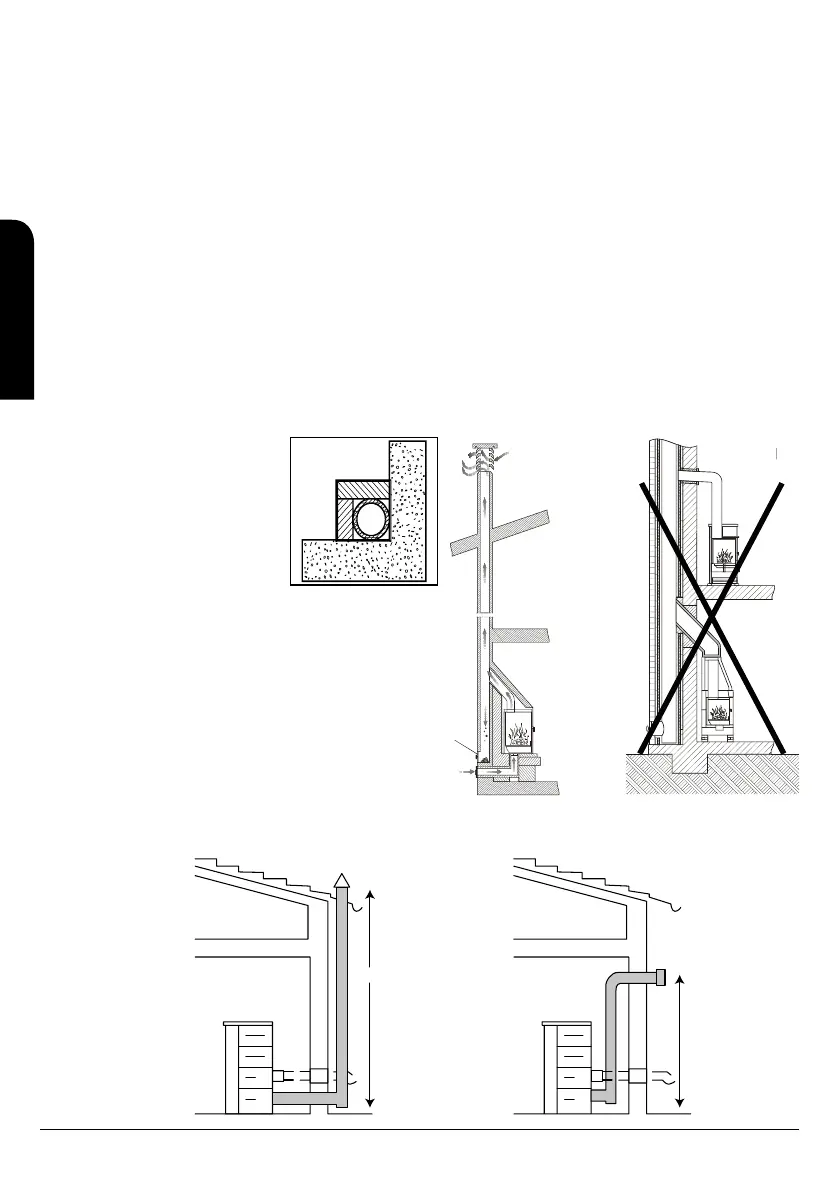

As far possible, avoid

horizontal sections. The

horizontal section will not

be longer than 3 meters.

It must be installed a “T”

with hermetic cover at the

stove exit smoke that allows

the regular inspection or

the heavy dust download.

There will not be more than

4 changes of direction,

including the register “T” for

the cleaning.

In drawing D11 are

represented the basic

requirements for the

chimney installation of the

stove:

D9

D10

D11

Altura mínima 1.5 m

Altura mínima 1.5 m

INSTALLATION, OPERATING AND SERVICING INSTRUCTIONS RADIOFREQUENCY SERIES

EN

Loading...

Loading...