S

tep

Sewn section Pattern

Step 3

(

Ba

ck

bar tack)

[c

ac

.o·

1. Turn the pattern selecti

on

dial to

•c•

(same

position as in step 1 ).

2. Sew 5

to

6 stitches.

3. Stop

the

machine

when

the

needle is

at

the

right

si

de

of

the

stitch

and

then raise

the

needle from

th

e

material.

Step 4

(Right side)

Dd

d

rn

1.

Set the pattern selection dial to •d".

2.

Sew the right side

until

the

need

le reaches

the

st

itches sewn

in

step 1 .

• Securing the Stitching and Cutting

th

e

Buttonhole

0

e

To

secure the stitching,

tum

the material

90 degrees counterclockwise and sew

straight

st

itches

to

the end of the front

bar

tack of the buttonhole.

Remove the material from the machine.

We recommend

that

you

put

pins across

both ends

of

the buttonhole

to

preve

nt

the

stitches from being cut.

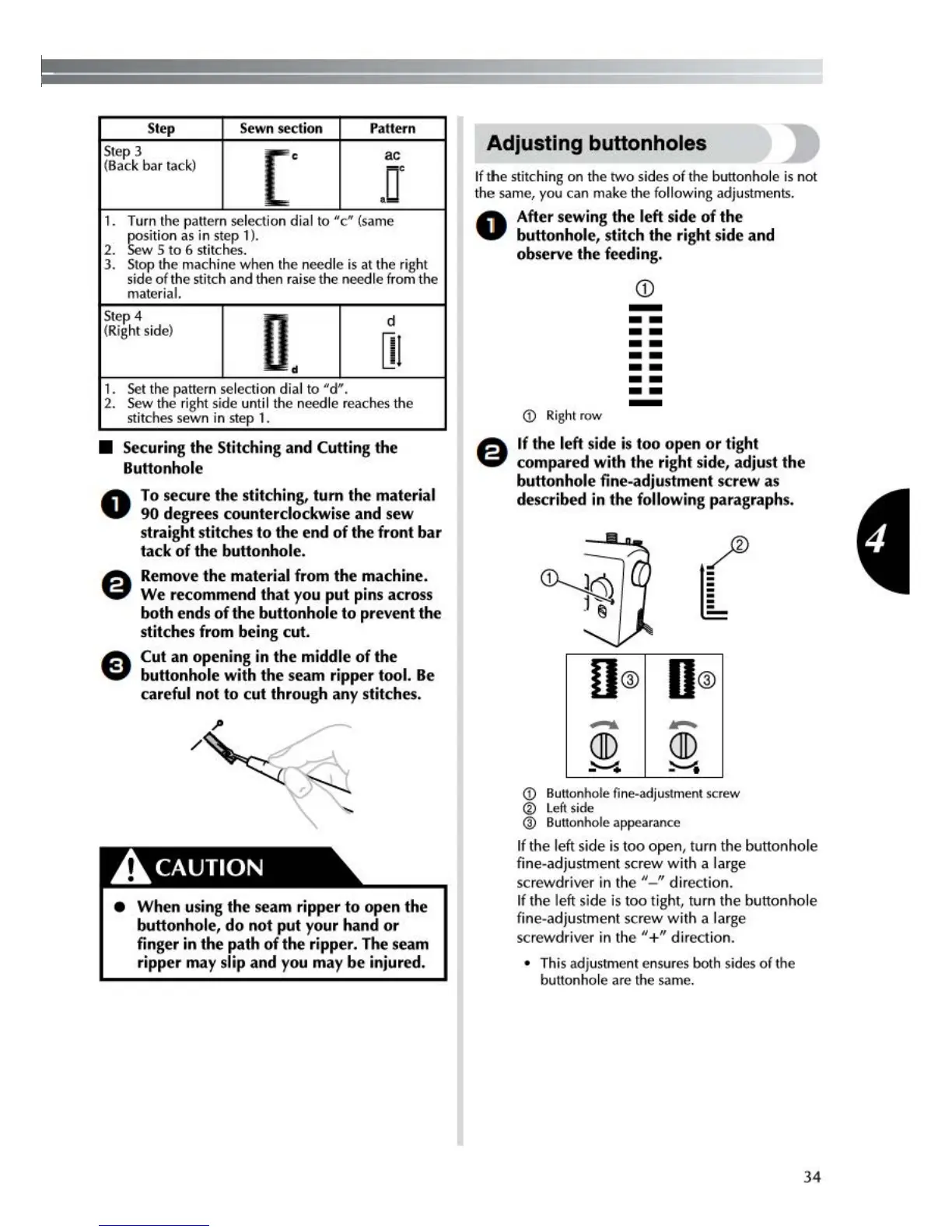

Cut

an

opening in

the

middle of the

buttonhole with the seam ripper tool.

Be

careful not

to

cut

through any stitches.

AcAur10N

• When using the seam ripper to open the

buttonhole,

do

not

put

yo

ur

hand

or

finger in the path

of

th

e ripper. The seam

ripper may

slip and you may be injured.

Adjusting buttonholes

If

the

st

itching

on

the

two

sides of

the

buttonhole is

not

the

same, you

can

ma

ke

the

following adjustments.

0

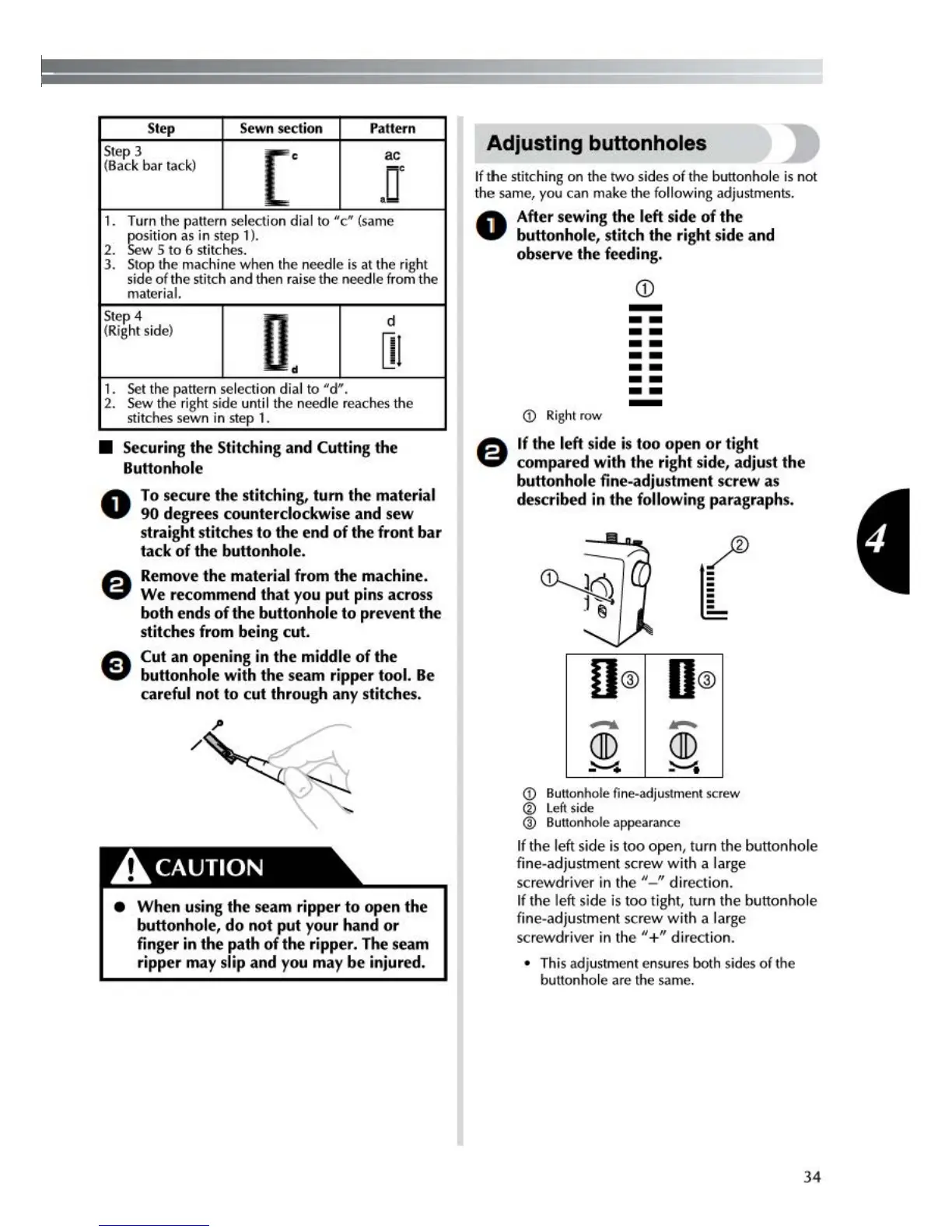

After sewing

th

e left side

of

th

e

buttonhole, stitch the right s

id

e and

ob

serve the feeding.

-

--

--

--

--

--

--

--

-

© Rig

ht

row

If

the left side is too open

or

tig

ht

compared with the rig

ht

s

id

e, adjust the

buttonhole fine-adjustment screw as

described

in

the following paragraphs.

/I>

~

l

j

'9

I)@

O@

-

-

<ID

~

<ID

~

© Buttonhole

fo

n

e·ad

juslm

enl

screw

<V

Left

si

de

@ Buttonhole

appearance

If

the

left

side

is

too

open,

turn

the

buttonhole

fine-

adjus

tm

ent

sc

r

ew

with

a large

screwdr

iver in

the

"- "

direction.

If

the

left

side

is

too

ti

ght,

turn

the

buttonho

le

fine-

adjus

tm

ent

sc

r

ew

with

a large

screwdr

iver in

the"+"

di

rectio

n.

• This adjustment ensures both sides of

the

buttonhole

are

the same.

34

Loading...

Loading...