29

MMAAIINNTTEENNAANNCCEE AANNDD IINNSSPPEECCTTIIOONN PPRROOCCEEDDUURREESS

This section includes instructions for

basic maintenance procedures. If you

have the necessary mechanical skills

and the required tools, you can per-

form these procedures. If not, see

your authorized Sea-Doo dealer.

WWAARRNNIINNGG

TToorrqquuee wwrreenncchh ttiigghhtteenniinngg ssppeecciiffii--

ccaattiioonnss mmuusstt bbee ssttrriiccttllyy aaddhheerreedd

ttoo..

LLoocckkiinngg ddeevviicceess,, wwhheenn rreemmoovveedd

((ee..gg..:: lloocckkiinngg ttaabbss,, eellaassttiicc ssttoopp

nnuuttss,, ccootttteerr ppiinnss,, eettcc..)),, mmuusstt bbee

rreeppllaacceedd..

Hoses, cables or locking ties removed

during a procedure must be rein-

stalled as per factory standards.

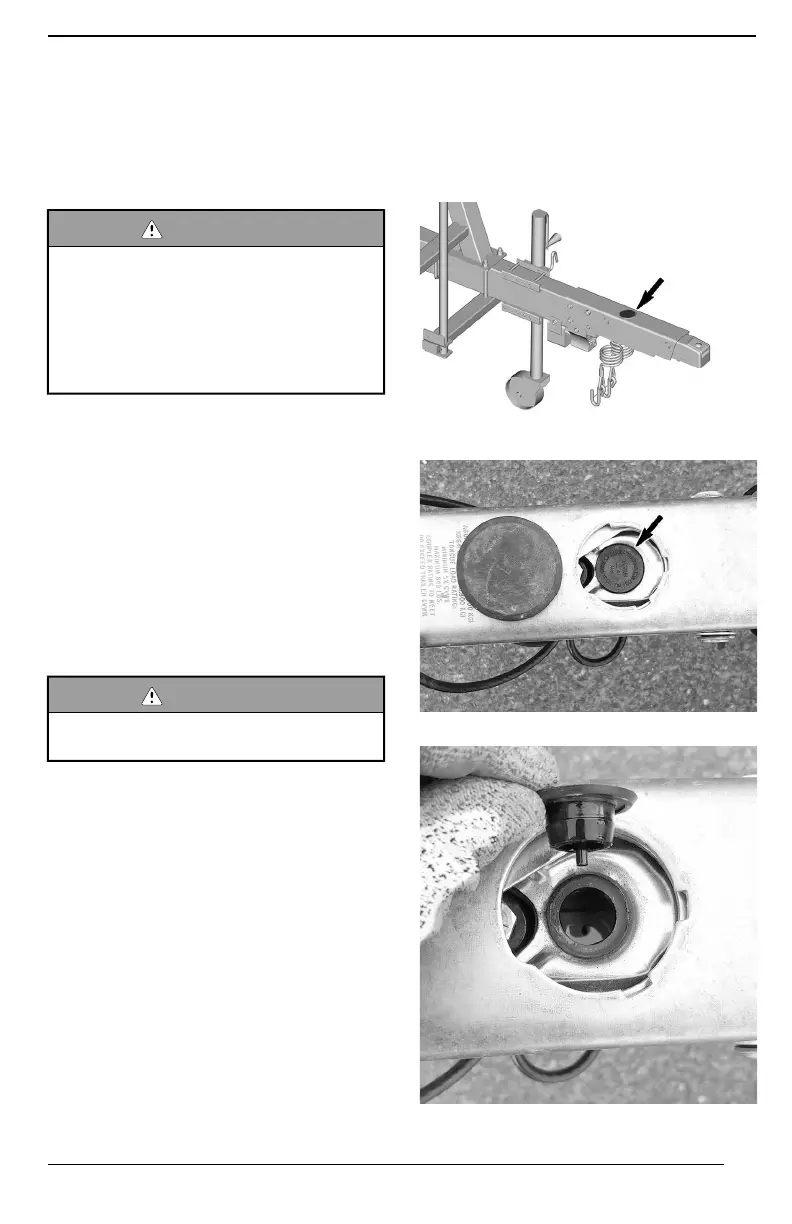

TToonngguuee SSaaffeettyy CCaabbllee

TToonngguuee SSaaffeettyy CCaabbllee IInnssppeeccttiioonn

Inspect for damage.

Discontinue use and contact an au-

thorized Sea-Doo dealer if cable or its

liner damage is found.

WWAARRNNIINNGG

DDoo nnoott uussee tthhee ttrraaiilleerr iiff ssaaffeettyy ccaa--

bblleess aarree ddaammaaggeedd..

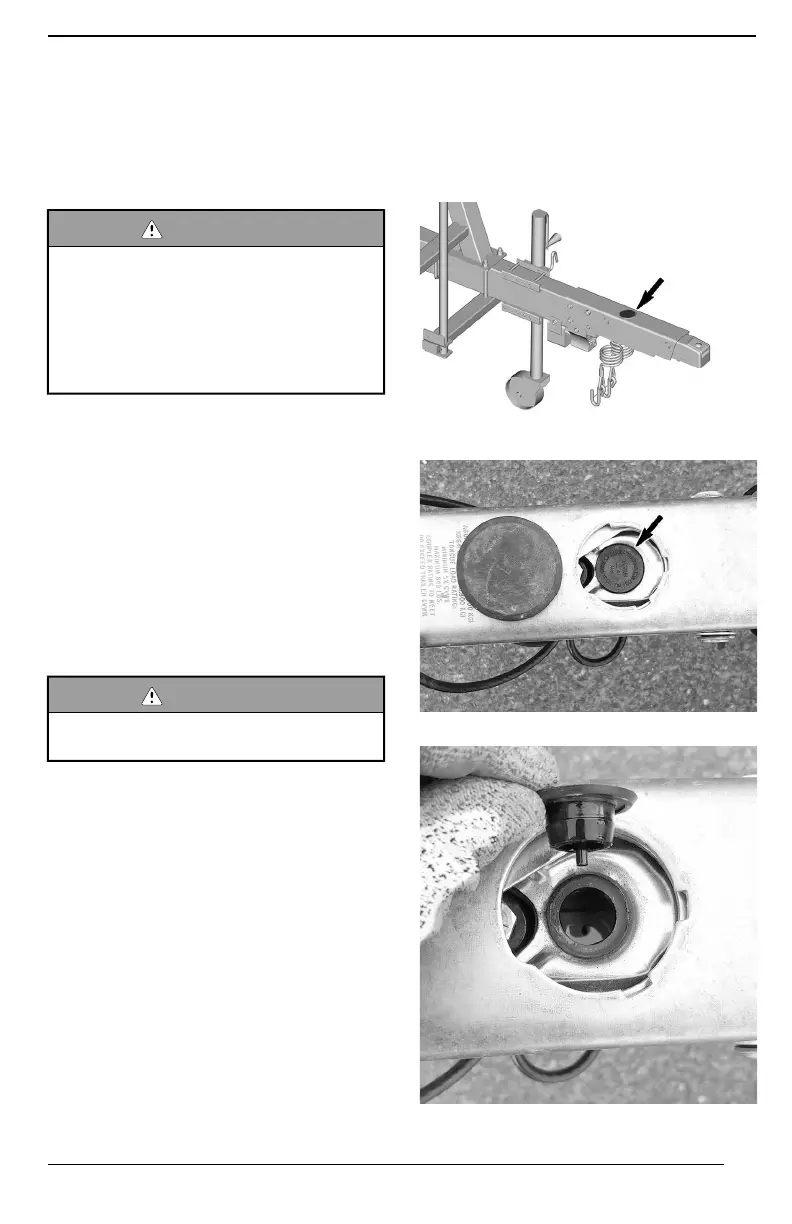

CCoouupplleerr

CCoouupplleerr IInnssppeeccttiioonn aanndd LLuubbrriiccaattiioonn

Check locking mechanism operation.

On brake equipped models, ensure

back-up lock pin is present.

Check ball socket, ball clamp and lock

mechanism for wear or damage.

Apply a thin coat of multipurpose

grease to the inner surface of the ball

socket.

Apply light oil to the pivot and sliding

surface of the lock mechanism.

BBrraakkeess ((iiff eeqquuiippppeedd))

BBrraakkee FFlluuiidd IInnssppeeccttiioonn

1. Remove master cylinder protective

cap on trailer tongue.

2. Removing master cylinder cap.

3. Check brake fluid level.

4. Reinstall master cylinder cap.

Loading...

Loading...