18

DP12VL

OPERATING INSTRUCTIONS

REPLACING THE BELT

SPINDLE RETURN SPRING

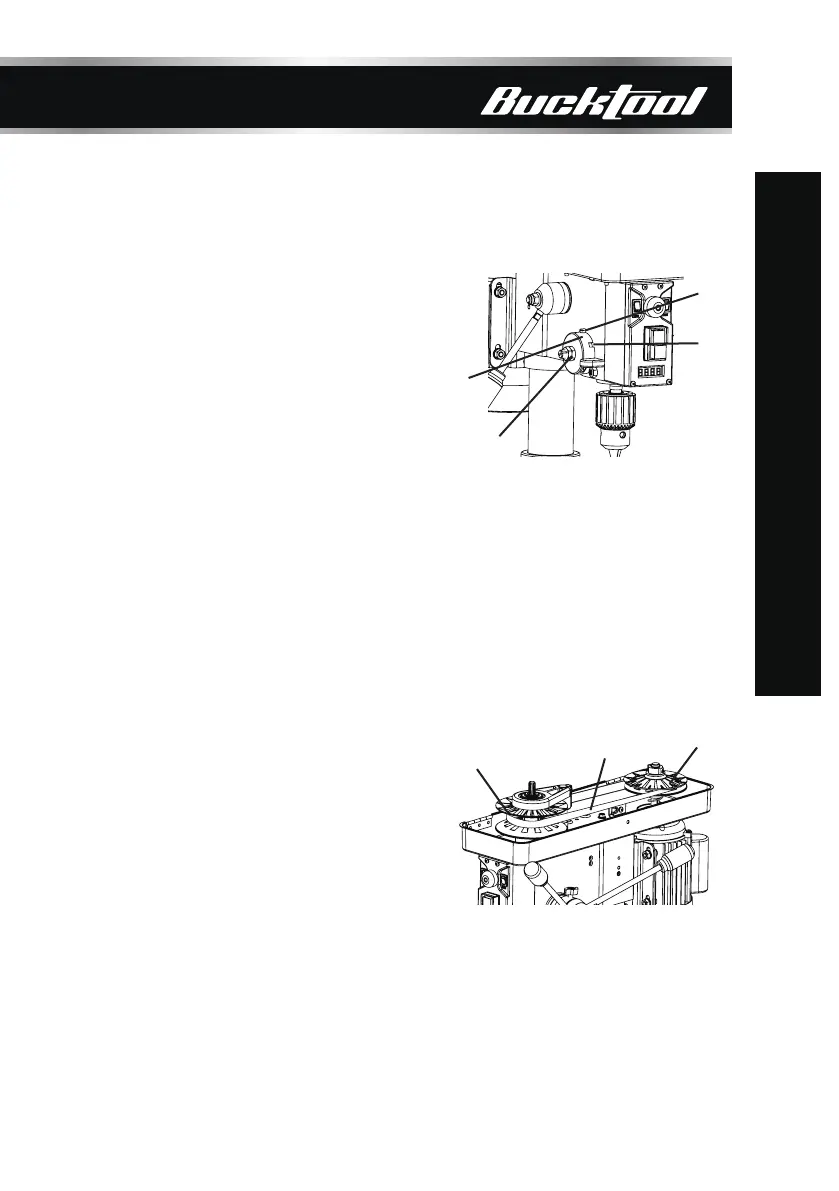

The spindle is equipped with an auto-return mechanism. The main components are a

spring and a notched housing. The spring was properly adjusted at the factory and

should not be readjusted unless absolutely necessary.

1. Unplug the drill press.

2. Loosen the two housing nuts (1) approximately

1/4" (6 mm). Do not remove the nuts from the

threaded shaft. Do not allow the spring or spring

housing to slip out of control.

3. While firmly holding the spring housing (2),

carefully pull spring housing out until it clears

the raised stop (3).

4. Turn the housing so that the next notch (4)

is engaged with the raised stop (3).

• To increase the spindle return tension, turn the spring housing counter-clockwise.

• To decrease the tension, turn the spring housing clockwise.

5. Tighten the two housing nuts. Do not overtighten the two nuts. If the nuts are

tightened too much, the movement of the spindle and feed handles will become

sluggish.

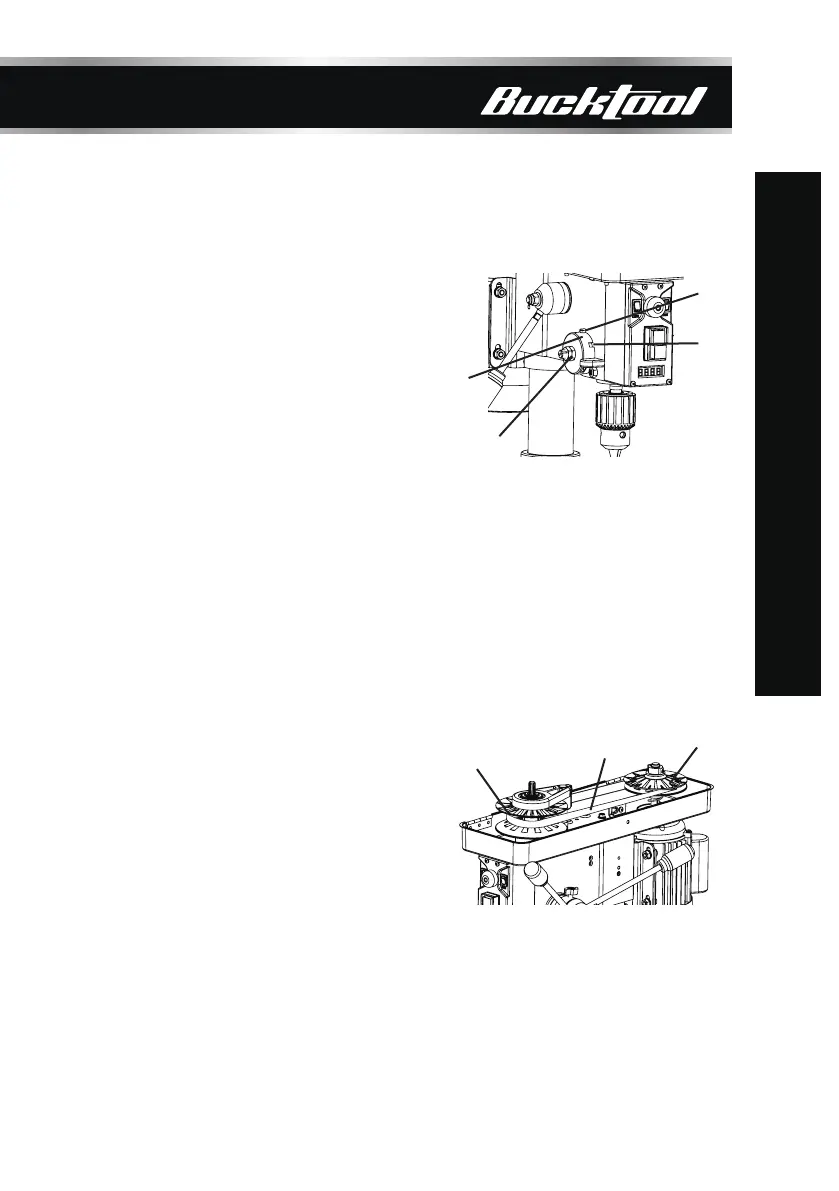

Belt tension and drill press speed is controlled by automatic adjustments made to the

diameter of the front spindle when the speed handle is moved.

1. Plug in the drill press and turn it ON. Adjust

the speed to the highest setting, then turn the

drill press OFF and unplug it.

2. Open the belt cover, remove the Phillips-head

screw from the right side, then open the lid.

3. Press down on the bottom side of the motor

pulley (2). This will loosen the belt tension.

Work the belt (1) off the pulleys.

4. Place the new belt on the motor pulley (1), then press down on the bottom side of the

pulley as before and get the belt as close to the motor shaft as possible. Make sure

the bottom side of the pulley is pushed fully downward.

5. Work the belt around the spindle pulley (3). The belt will not be taut, but will self-seat

later.

6. Close and secure the belt cover.

7. Plug in and turn ON the drill press. The belt will self-seat and achieve proper tension

on its own.

2

3

1

1

2

3

4

Loading...

Loading...