PREPARING TO INSTALL

INSTALL SLIDER BASE

The Companion base will mount to four attachment

points in the truck bed. Remove any debris and/or

obstructions from the truck bed, this includes any

plastic caps which may be over the attachment points.

Remove the latch pins from each side of the base and

rotate the handles out, see Figure B1. Place the base

over the attachment points and carefully lower it until

the latch cams pass through the floor and the base

rests flat against the top of the attachment points.

Prepare to adjust latch tension. Once the base is

in place, remove the cotter pins from each of the four

castle nuts. Engage the cams with each attachment

point by turning the latch handles back to their locked

position, see Figure B2. If a handle will not turn easily,

loosen the castle nut until the cam will freely turn and

engage the attachment point.

Adjust the tension in the latch handle, for parts list

and visual guide refer to Figures B5 and B6.

With the handles in the latched position, tighten the

castle nut until snug to increase the tension on the

latch. Rotate the latch handle open and closed.

Tighten the castle nut slightly and rotate the handle

open and closed again. Repeat this process until you

feel the cam engage the attachment point while

closing the handle. The handle is set at the proper

tension when there is friction between the cam and

attachment point but the handle can still be closed by

hand without bumping, tapping, or otherwise forcing

the handle closed.

1.

Adjustment instructions continued on next page.

3.

WARNING:

The latch cams and handles must be

adjusted to fit the tow vehicle. Failure to properly

adjust the cams and handles may result in property

damage and/or personal injury.

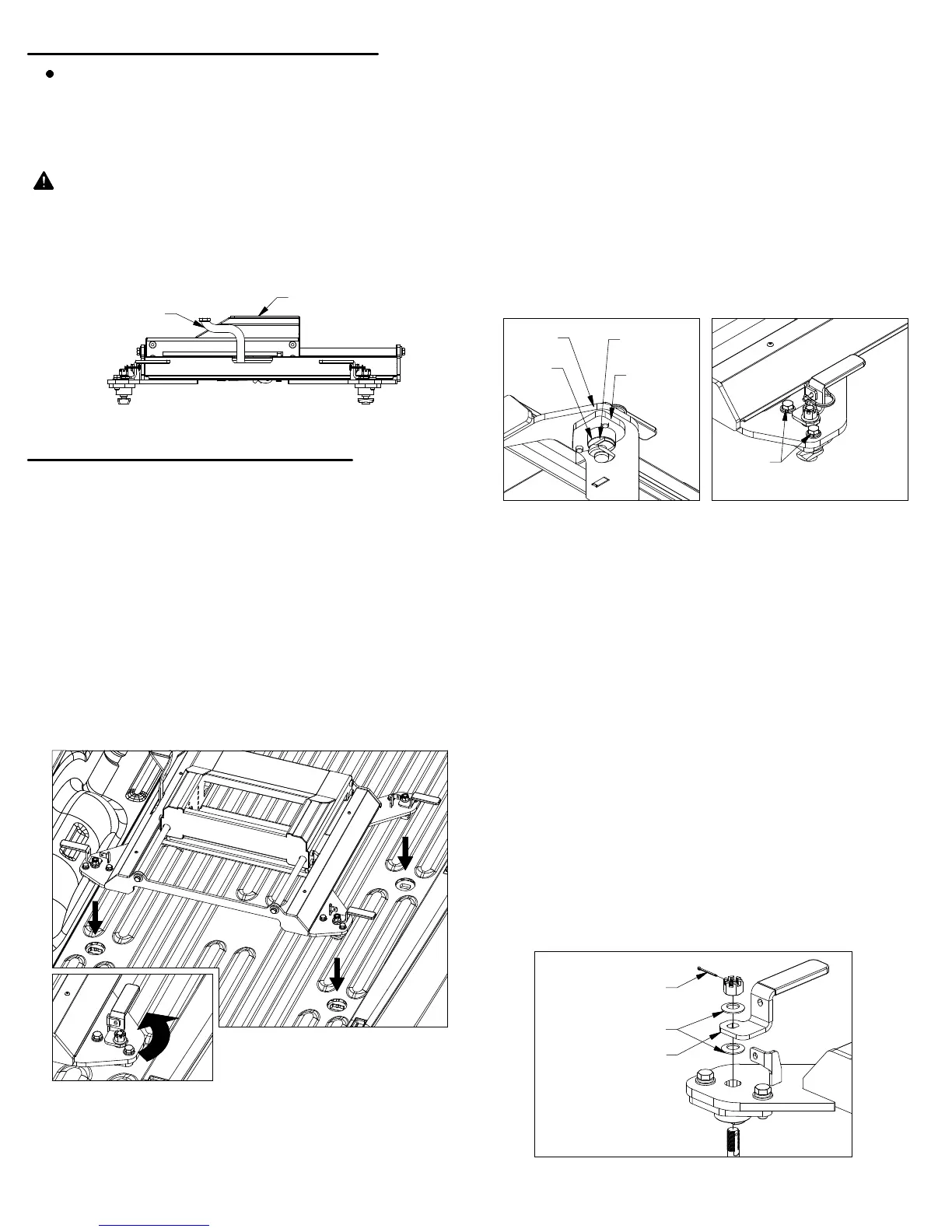

Each leg of the Companion base has an adjustable pilot

assembly which is attached to the foot with two 1/2" cap

screws, as shown in Figure B4. To adjust the pilot

assemblies that do not fit into the attachment points,

loosen both the 1/2" cap screws so the pilot assembly

can move freely, see Figure B4. Set the base over the

attachment points and adjust the pilot assemblies until

the pilot keys pass through the slot in the attachment

points and the pilot shoulders rest flat against the top of

the attachment points. When all the pilot assemblies

are aligned and inside the attachment points, push the

base towards the cab and use a tape measure to verify

that the base is approximately square with the truck

bed. Tighten any loose cap screws to 80 ft−lbs.

2.

Remove any debris and/or obstructions from the truck

bed, this includes any plastic caps which may be over

the attachment points. It may also be necessary to

remove the plastic grommets from around the mounting

points in order to fully seat the base down to the truck.

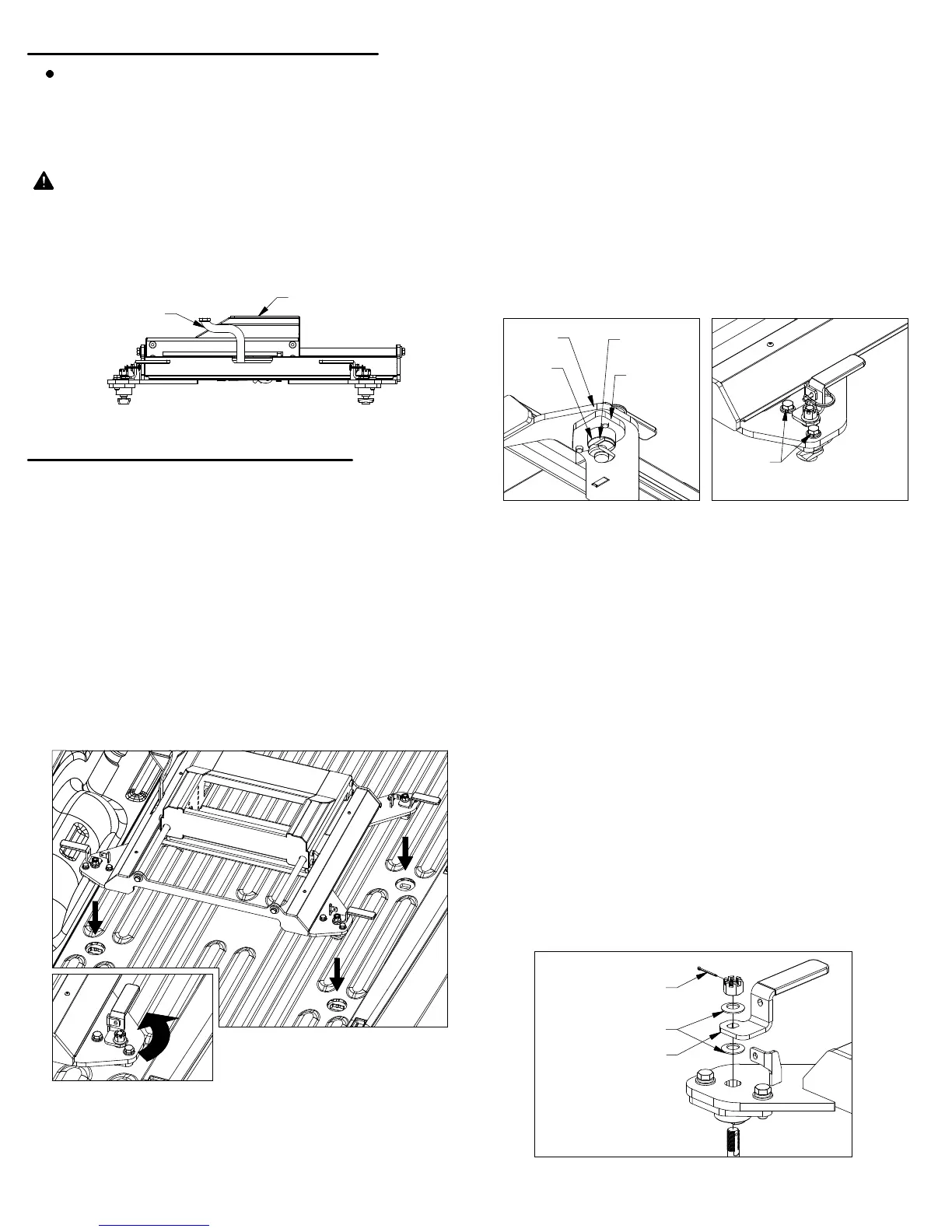

WARNING: Whenever the slider base is being

moved, the slider handle must be in the locked

position, and the carriage must be unable to slide,

see Figure A1. Failure to ensure that the handle is in

the locked position can lead to property damage, or

serious injury.

PAGE 2 of 5

IMPORTANT: The attachment points may differ from

truck to truck. If the pilots fit into the trucks

attachment points you may skip Step 2 and continue

with Step 3. If the Companion base does not fit into

the attachment points proceed to Step 2.

4.

Figure A1: View of driver side of Slider Base.

Figure B1:

View of unlatched base.

Figure B2: View of closed latch handle.

Figure B3: View under base foot

Figure B4: View of base foot

Figure B5: List of latch parts.

SLIDER HANDLE

IN LOCKED POSITION

SLIDER CARRIAGE

1/2" CAP

SCREW

PILOT

ASSEMBLY

BASE

FOOT

PILOT

KEY

PILOT

SHOULDER

COTTER PIN

LATCH HANDLE

FLAT WASHER

Loading...

Loading...