Figure D3: Base view.

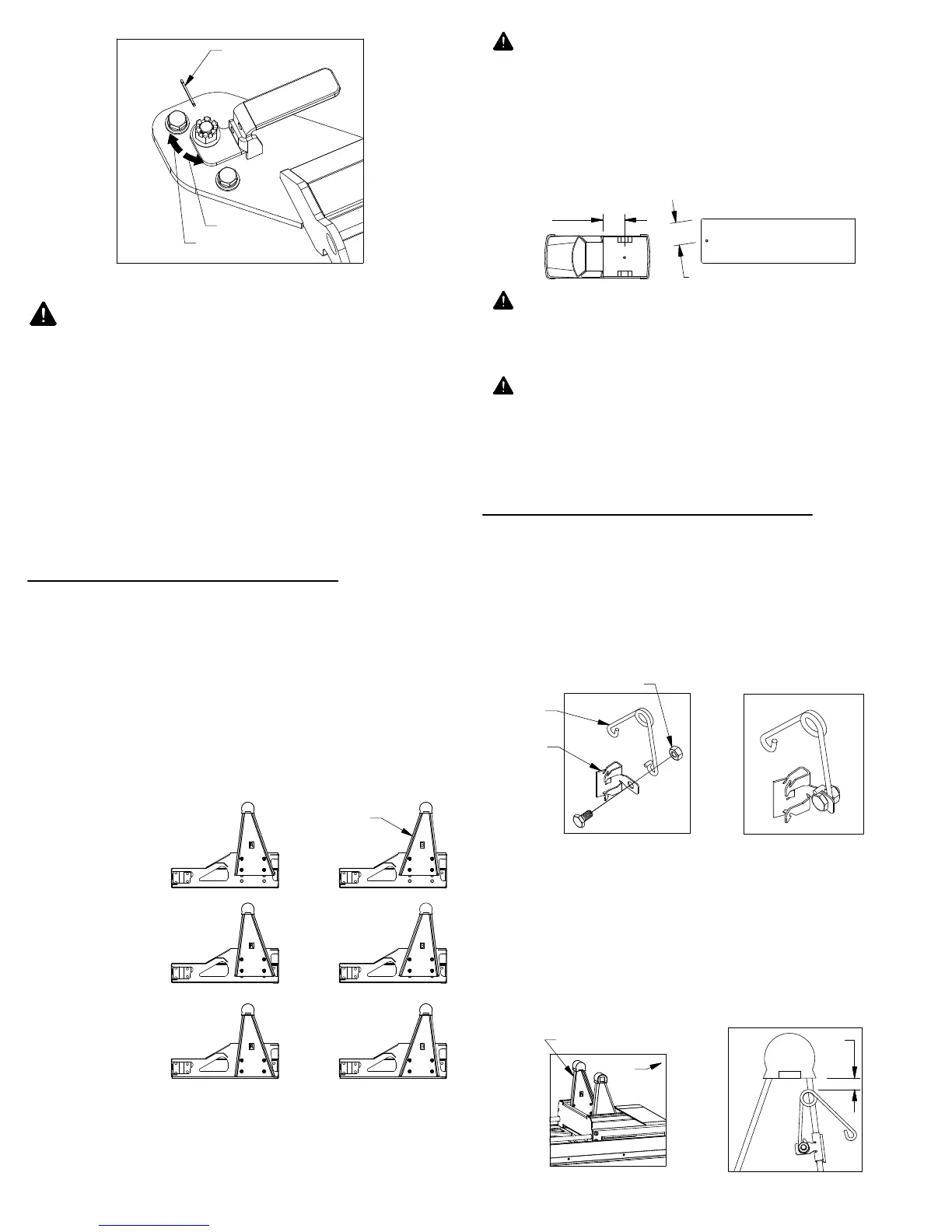

Figure C1: Cut away view of slider carriage arm positions.

WARNING: Check the clearance between the truck

cab and the trailer in both the towing position and the

maneuvering position. Compare the measurement

taken from the center of the Slider Coupler to the cab,

to the measurement taken from the center of the king

pin to the farthest forward corner point of the trailer.

These measurements will allow you to see how much

clearance you will have between the cab and the

trailer while towing and turning.

WARNING: Check the clearance between the bed

side and the underside of the front of the trailer and to

allow adequate clearance for the pitch and roll of the

trailer while towing.

WARNING: Parts of the trailer may strike the tailgate

when sliding the companion rearward. Check the

clearance between the tailgate and trailer components

such as the trailer tongue or pin box. Failure to check

clearance may cause property damage.

INSTALL PIVOT ARMS

Mount the pivot arms using one of the six different

locations illustrated in Figure C1. These six locations

allow flexibility in coupler height and distance from the

cab. Choose a location so that your trailer will be as

level as possible and have adequate turning clearance

while in the towing position (with the slider in the

forward position). See warnings after step 2.

With the base firmly held down and each latch handle

closed, replace the latch pins removed in Step 1.

NOTICE: Verify latch tension each time the

Companion base is placed in a truck, and periodically

before towing.

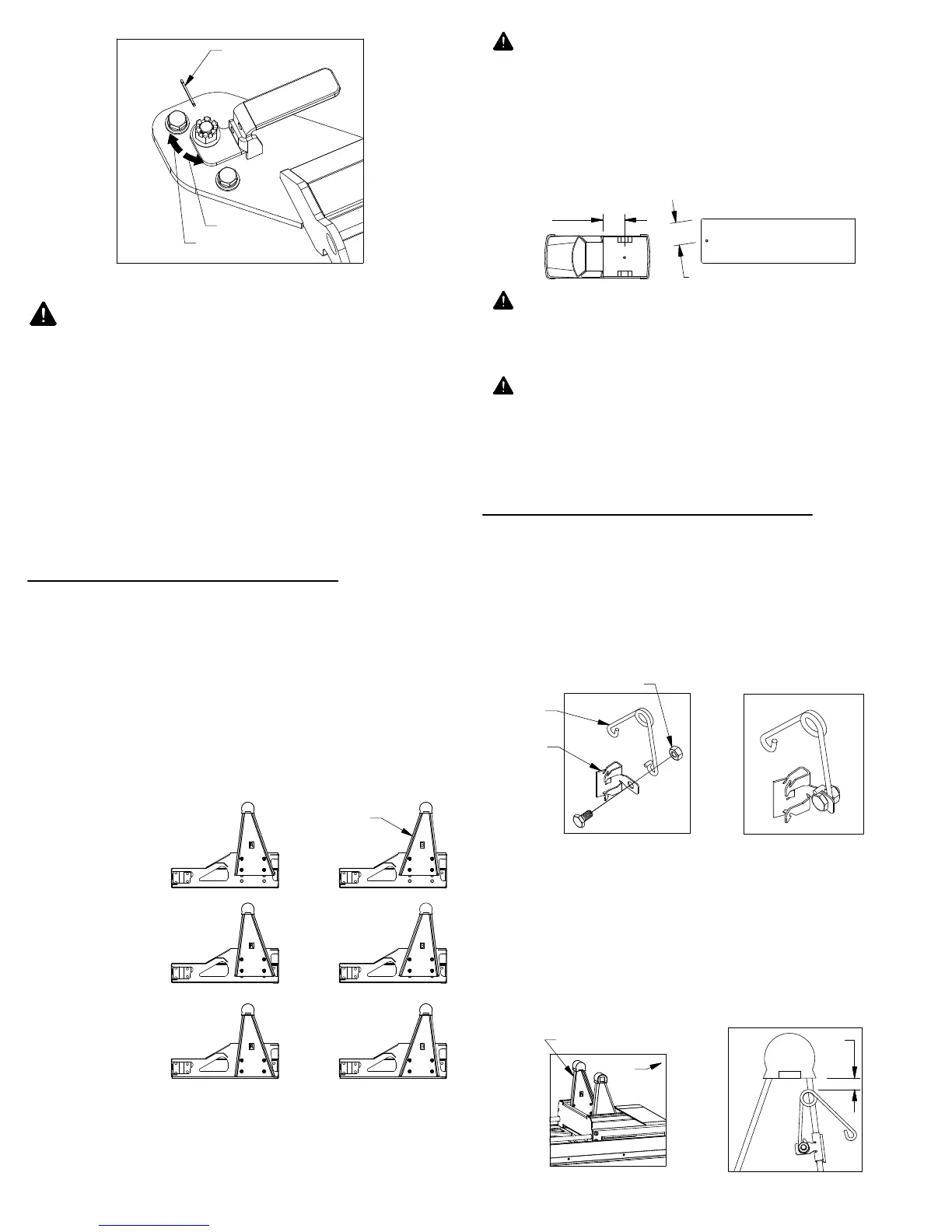

Locate the 1/4" cap screw and nut, along with the wire

tension spring and mounting clip. Pass the 1/4" cap

screw through the mounting clip and the wire spring,

as shown in Figure D1. Thread the 1/4" lock nut onto

the 1/4" cap screw. Tighten the lock nut just enough

that the spring will stay in place but will still be able to

rotate around the bolt if needed, see Figure D2.

INSTALL LEVELING KIT

Locate the flange which will be closest to the truck cab

on the driver side pivot arm, see Figure D3. The clip

should be placed so that when the spring’s coil is in

line with the edge of the arm there will be 1/2" of

clearance between the bottom of the rubber bumper

and the top of the spring, see Figure D4. Drive the

clip securely onto the flange with a hammer.

2.

1.

With the flat side of the pivot arm flat against the bolt

plate in the slider base, install four 1/2" x 2" bolts and

four 1/2" split lock washers for each arm. Torque each

bolt to 80 ft−lbs.

2.

1.

PAGE 3 of 5

5.

WARNING:

Setting latch handle tension so that

excessive force is required to close the latch handles

may result in property damage and/or personal injury.

Figure D2:

Assembled leveling kit.

Figure D1:

Leveling kit parts.

Figure D4: Driver side pivot arm.

BED FLOOR TO TOP OF

COUPLER

KINGPIN 2"

IN FRONT OF AXLE

POSITION CLOSEST TO CAB

KINGPIN OVER AXLE

POSITION FARTHEST FROM

CAB (ARMS REVERSED)

HIGHEST

POSITION

(19")

MIDDLE

POSITION

(18")

LOWEST

POSITION

(17")

Figure B6: View of base leg.

CENTER OF

COUPLER

TO CAB

KINGPIN TO EDGE OF TRAILER

WIRE

SPRING

1/4" LOCK NUT

MOUNTING

CLIP

1/2"

DRIVER SIDE PIVOT ARM

CAB

PIVOT ARM

COTTER PIN

LOOSEN

TIGHTEN

Loading...

Loading...