E

N

L

N

L

L

N

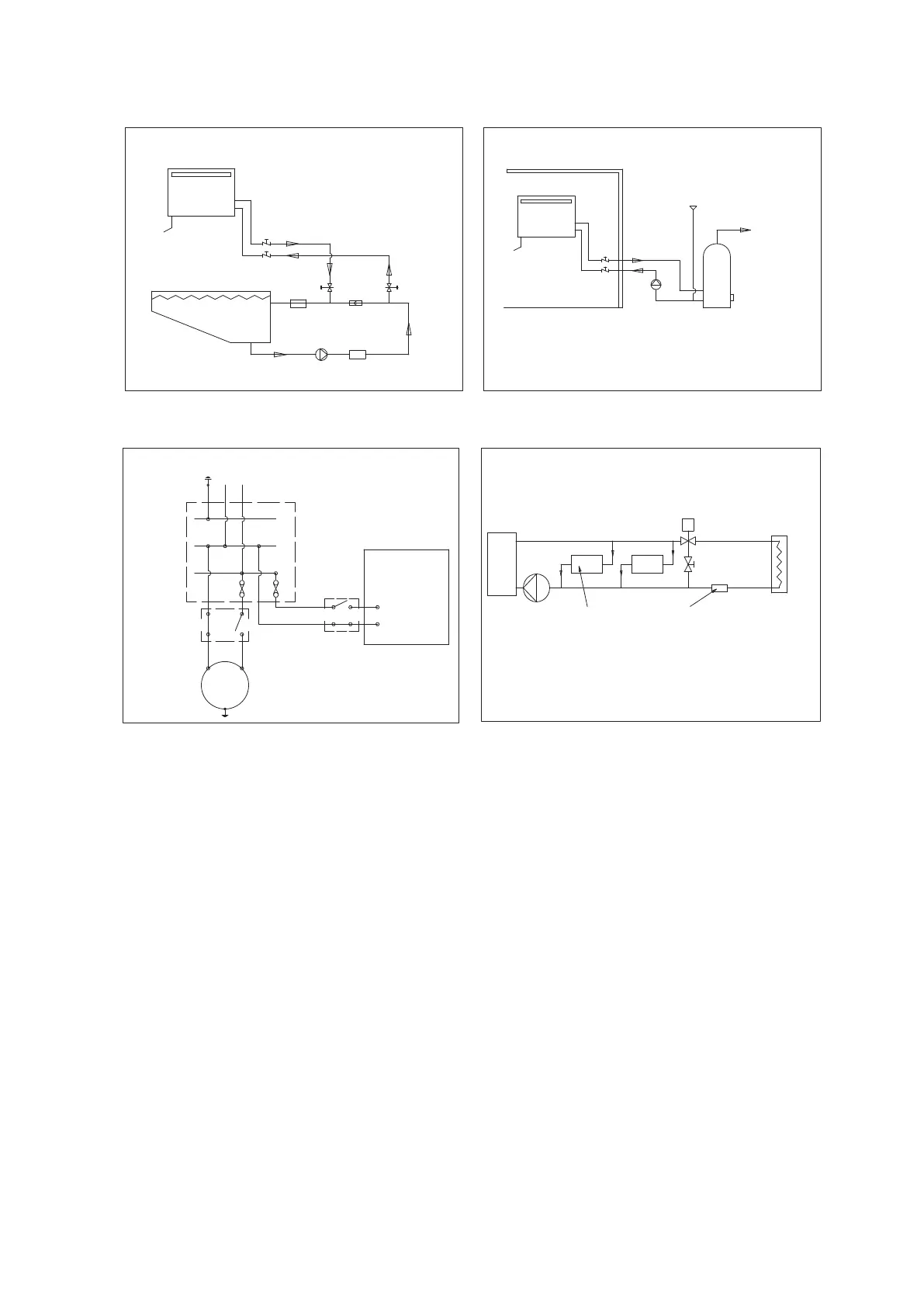

PLUMBING CIRCUITS HEAT RECOVERY MODELES 'RH'

HEAT RECOVERY TO POOL/SPA

DRAIN

DRAIN

DESHUMIDIFIED SPACE

3PSI

NRV

SANITISER

PUMP FILTER

DEHUMIDIFIER

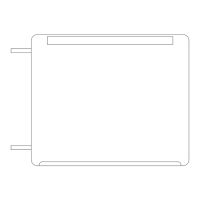

HEAT RECOVERY TO WATER

WATER

PUMP

COLD WATER

FEED

HOT WATER

CYLINDER

INSULATED

HOT WATER

DRAIN OFF

CYLINDER

STAT

WATER CIRCUIT

COMPONENTS REQUIRED

INSULATED DIRECT HOT WATER

CYLINDER

WATER PUMP, THERMOSTAT

INSULATED PIPING

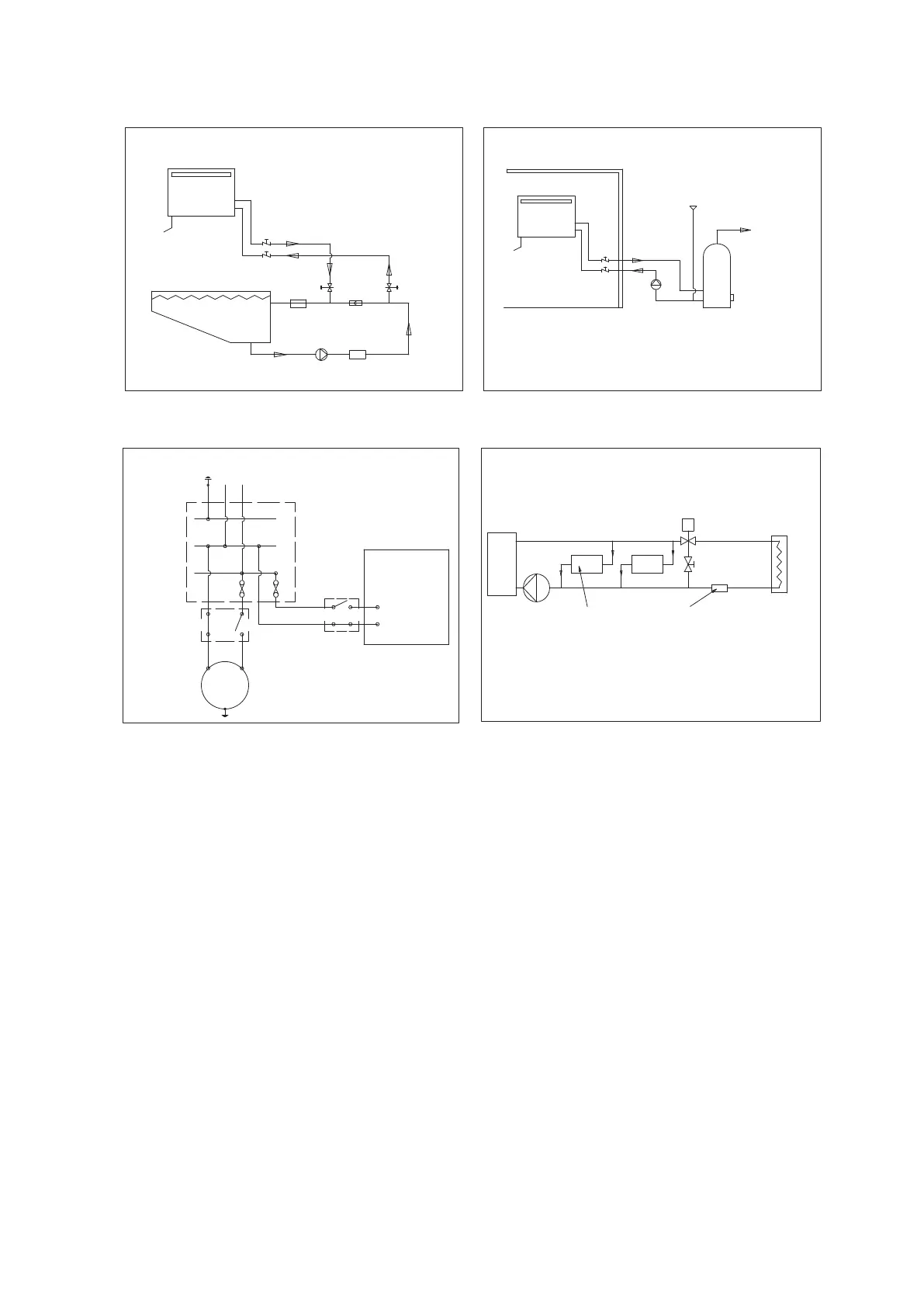

ELECTRICAL SUPPLY CIRCUITS

LPHW PLUMBING SCHEMTIC

DEHUMIDIFIER

INCOMING SUPPLY. CAPACITY TO SUIT

PUMP AND DEHUMIDIFIER

AUX

FUSEBOARD

ISOLATOR

TO SUIT

PUMP

WATER

PUMP

WATER PUMP IS FOR HEAT RECOVERY,

POOL/SPA OR HOT WATER APPLICATIONS

SINGLE PHASE

LOCAL ISOLATOR.

CAPACITY TO SUIT DEHUIDIFIER

BOILER

PUMP

RADIATORS IF

FITTED

FLOW METER

3 WAY MOTORISED VALVE

CONTROLLED BY

CUSTOMERS THERMOSTAT

FLOW BALANCE

VALVE

LPHW

CONNECTIONS

LOCATED ON

DEHUM CABINET

OPERATION

A recommended humidistat setting (50-60% RH) is a mid way point on

e dial (Green segment on label).

Minimum Air Temp DH30/33/50/55 A = 15ºC

Minimum Air Temp DH30/33/50/55/ AX = 0ºC.

Note on “X” models e fan stops during defrost.

On machines wi resistance heaters DH30/50 “P” heating control is

governed by e remote mounted air ermostat, adjust to desired air

temp, heater will run automatically as required.

On machines wi LPHW,fans will start automatically as required.

MAINTENANCE

a) Ensure air inlets/outlets are kept clear and clean. Filter kits are

available.

b) Wipe clean wi damp clo or cleaning fluid suitable for fibreglass

and/or PVC.

c) Ensure drain line is kept clear.

Note: Thre reply paid Warranty Registration Card must be returned to

ensure e correct warranty is given. If you do not find a Registration

Card wi your machine please contact CALOREX Service Department

giving your name, address, and e serial number of your machine. A

card will be sent to you for completion.

HEALTH AND SAFETY WARNING

As e heat pump contains electrical and rotational equipment, it is

recommended at ONLY competent persons carry out any work on is

type of machine (see guarantee).

Isolate machine electrically before entering machine or removing panels.

PLEASE LEAVE INSTRUCTIONS FOR USER

MACHINE NOT RUNNING AT ALL

CHECK THE FOLLOWING

1 Is e supply switched on?

2 Is e supply fuse healy?

3 Turn humidistat knob fully anti-clockwise.

4 Check air inlets and outlets for obstructions.

5 ON P models reset e ermostat(s) see FIG 3.

6 If aer carrying out e above and waiting one hour, e machine

does not start, phone for service.

MACHINE FAN ONLY RUNNNING

7 Turn humidistat knob fully anti-clockwise.

8 Check air inlets and outlets for obstructions, if aer 30 minutes e

machine has not restarted, phone for service.

WATER LEAKING FROM BASE OF UNIT

9 Check connection from machine to drain for blockages and clear

accordingly, check fall is adequate.

10 Check e machine is level, bo vertically and horizontally.

The user check list should be carried out before initiating a service call.

Do not attempt to interfere wi any internal control settings as ese

have been factory calibrated and sealed.

If in doubt or if advice is required, contact Calorex Service Department

Telephone (01621) 856611 (option 4) or

email service.department@danerm.com

Loading...

Loading...