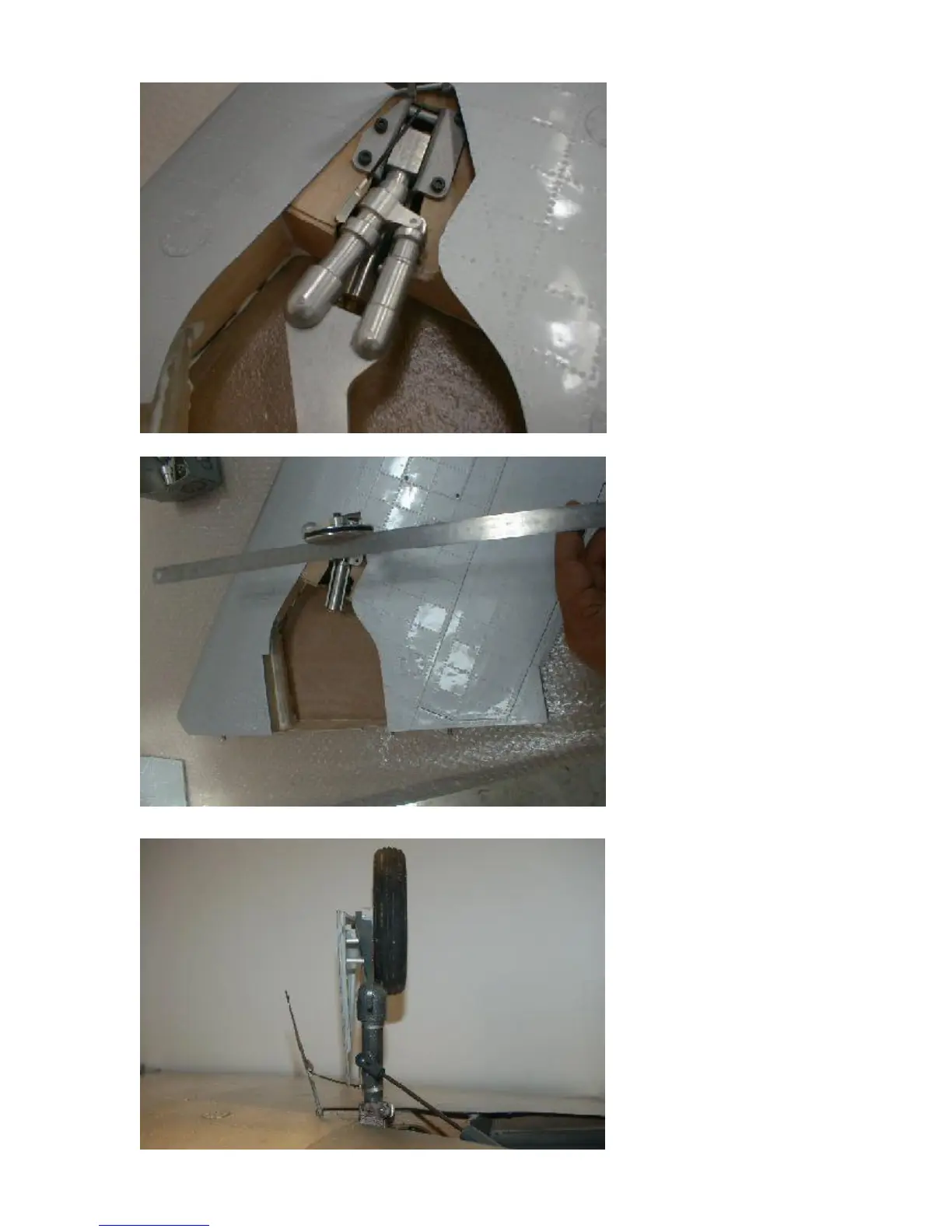

After it is confirmed that the

gear fits the gear well, mark

the position of the holes for the

mounting screws with a pencil,

and take the gear out.

Then drill 5.5 mm holes, insert

the T-nuts and trial mount the

landing gear.

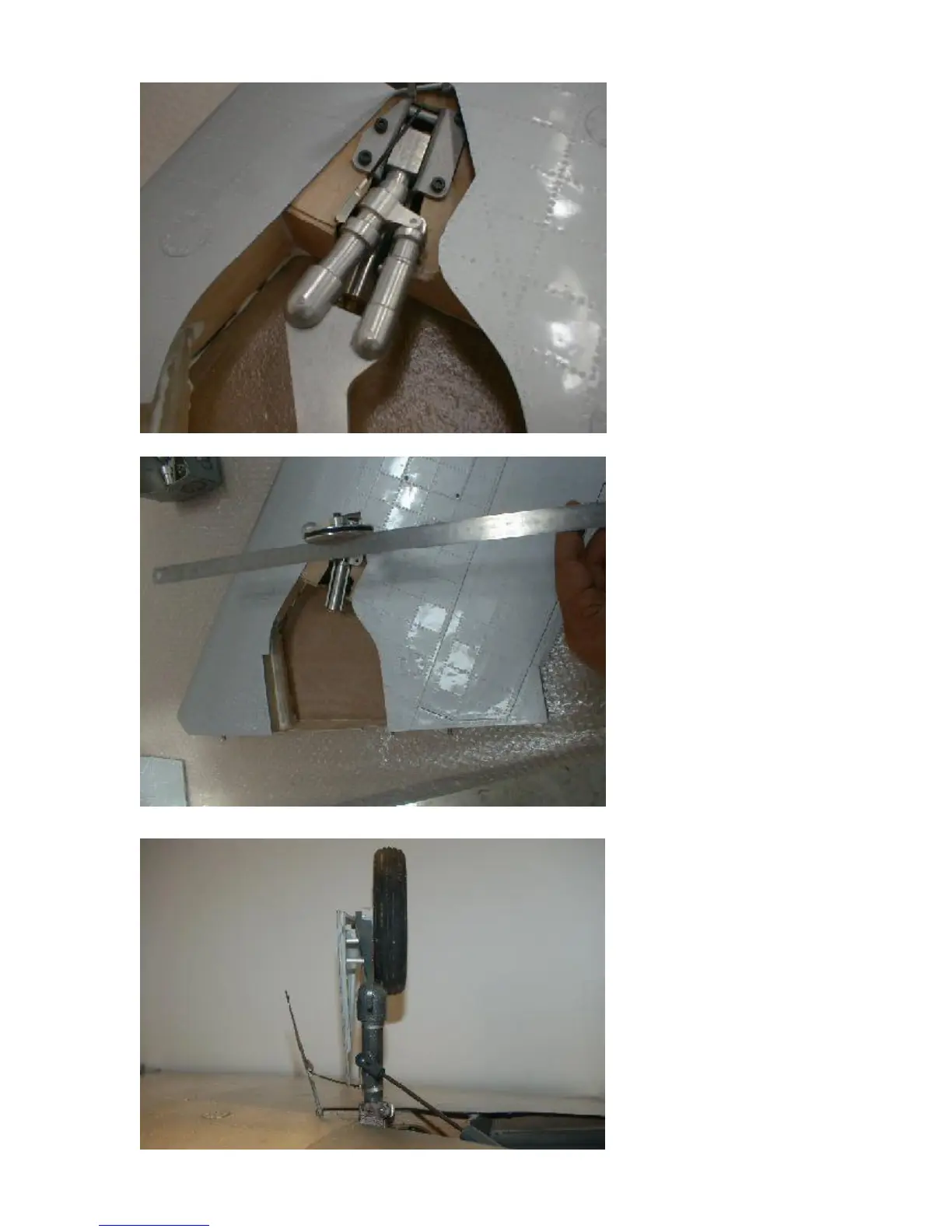

Now move the gear strut in

and out, to simulate a

retracting cycle. You see now,

how many angles have to be

correct, so that the wheel is

- flat and parallel in the gear

wells, when retracted

- parallel to the root rib

when extended,

- not hitting anything during

the retracting cycle

that the strut is

- exactly correct positioned

in the gear wells when

retracted

- hidden under the bottom

wing surface, to accept the

gear doors alligned to the

bottom wing contour

- exactly vertical in side

view, when extended

- exactly vertical in the front

view, when extended.

and finally, that the gear unit is

low enough, that it can be

covered with the outer small

gear door, which will have to

be connected with the main

strut.

The front two monting screws

are counter sink screws to

allow the small gear door to

close propperly, there is not

enoungh room for regular allan

heads. The 2 rear screws are

regular M4x20 allan hed

screws.

Loading...

Loading...