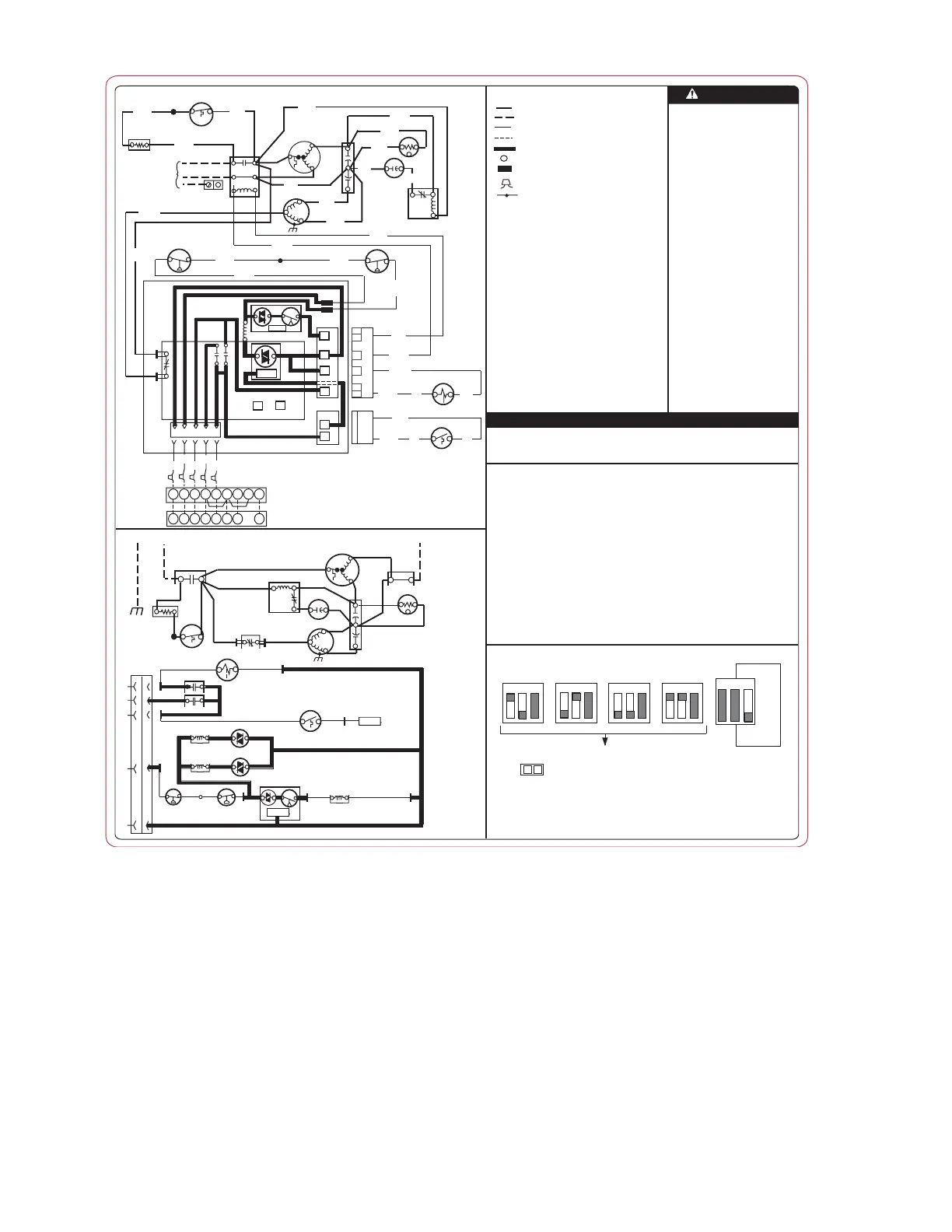

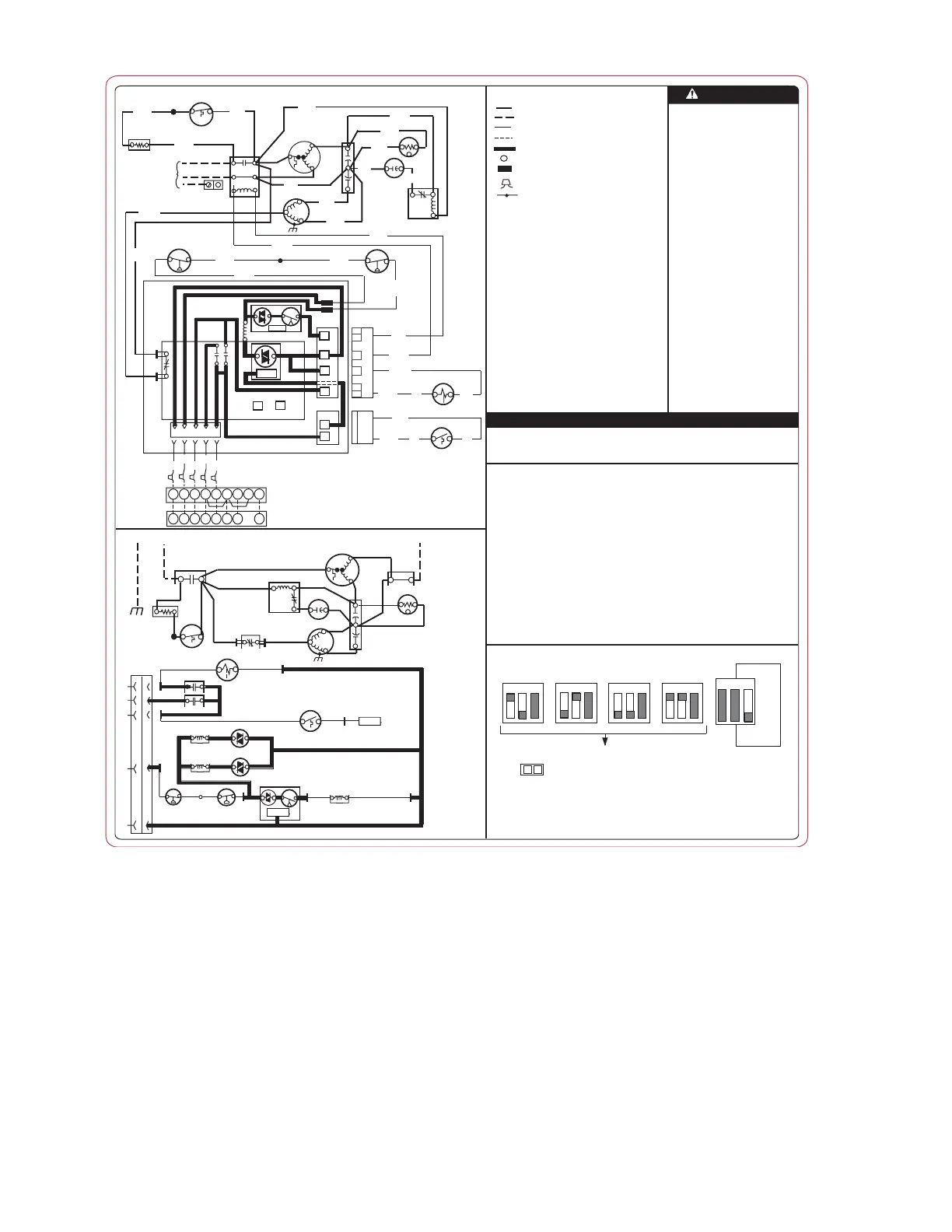

Fig. 1—Label Wiring 327207-101

A05014

SPEED

UP

THIS DEFROST CONTROL BOARD CONTAINS A FIVE MINUTE SHORT CYCLE

PROTECTOR. A FIVE MINUTE DELAY WILL OCCUR BETWEEN COMPRESSOR

OFF/ON CYCLES.

* MAY BE FACTORY OR FIELD INSTALLED

COMP COMPRESSOR

CTD COMPRESSOR TIME DELAY

CONT CONTACTOR

CB CIRCUIT BOARD

DFT DEFROST THERMOSTAT

DR DEFROST RELAY AND CIRCUITRY

*HPS HIGH PRESSURE SWITCH

*LPS LOW PRESSURE SWITCH

OFM OUTDOOR FAN MOTOR

RVS REVERSING VALVE SOLENOID

RVSR REVERSING VALVE SOLENOID RELAY

*SC START CAPACITOR

*SR START RELAY

*ST START THERMISTOR

FIELD SELECTABLE OPTIONS FOR TIME PERIOD BETWEEN DEFROST

CYCLES (MINUTES)

- LEGEND -

123

123

123

123

30 MINUTES 60 MINUTES

(DEFAULT)

90 MINUTES

120 MINUTES

120

30

OR

OR

OR

60

90

DIP SWITCH SETTINGS

123

QUIET

SHIFT

ON

OFF

(DEFAULT

NOTE

1) MOMENTARILY SHORT PINS AND RELEASE TO BYPASS COMPRESSOR OFF DELAY.

2) SHORT FOR 5+ SEC. AND RELEASE FOR FORCED DEFROST.

3) PERMANENT SHORT WILL BE IGNORED. DEFROST WILL TERMINATE IN 30 SEC. IF

DFT OPEN. DEFROST WILL TERMINATE NORMALLY IF DFT IS XLOSED.

FACTORY POWER WIRING

FIELD POWER WIRING

FACTORY CONTROL WIRING

FIELD CONTROL WIRING

CONDUCTOR ON CIRCUIT BOARD

COMPONENT CONNECTION

1/4-INCH QUICK CONNECT TERMINALS

FIELD SPLICE

JUNCTION

AUXR AUXILLARY HEAT RELAY

CAP CAPACITOR (RUN)

*CH CRANKCASE HEATER

*CHS CRANKCASE HEATER SWITCH

- NOTES -

1. Compressor damage may occur

if system is over charged.

2. This unit is factory charged with

R-22 in accordance with the

amount shown on the rating plate.

The charge is adequate for most

systems using matched coils and

tubing not over 15 feet long. The

best performance will be

achieved when the

unit operates with a suction gas

superheat at the compressor inlet

of 5ºF at normal rating

conditions of the air conditioning

and refrigeration institute (ARI).

This chart may be used to

approximate the charge if ARI

rating conditions cannot be

obtained. ARI rating conditions

are equivalent to DOE test "A"

conditions. See product data

literature for required indoor air

flow rates and for use of line

lengths over 15 ft.

3. Relieve pressure and recover all

refrigerant before system repair or

final unit disposal. Use all service

ports and open all flow-control

devices, including solenoid valves.

CAU

TIO

N

JUMPERED TEST PINS (USE METAL OBJECT), FIELD SPEED-UP CYCLE

327207-101 REV. A

CONNECTION DIAGRAM

SCHEMATIC DIAGRAM

(LADDER FORM)

1. Compressor and fan motor furnished with inherent thermal protection.

2. To be wired in accordance with National Electric Code (N.E.C.) and local codes.

3. N.E.C. class 2, 24 V circuit, min. 40 VA required.

4. Use copper conductors only, from disconect to unit.

5. Must use thermostat and sub-base as stated in pre-sale literature.

6. If indoor section has a transformer with a grounded secondary, connect the

grounded side to "C" on the circuit board.

7. If any of the original wire, as supplied, must be replaced, use the same or

equivalent wire.

8. Check all electrical connections inside control box for tightness.

9. Do not attempt to operate unit until service valves have been opened.

10. When LPS and HPS are not required, a jumper will be installed between

Y and T1 on the defrost board.

11. Use conductors suitable for at least 75ºC (167ºF).

+t°

BLU

*ST

YEL

BLK

*CHS

YEL

YEL

5

2

1

YEL

GLER

W2

OYC

TERMINAL BLOCK

INDOOR UNIT

RED

WHT

ORN

YEL

BLK

CB

G

W3

LER

W2

OYC

BLU

BRN

YEL

*HPS

*LPS

2323

21

11

BLU

S

C

R

YEL

BRN

L2

L1

BLK

CONT

EQUIP

GND

INDOOR THERMOSTAT (NOTE #5)

SUPPLY

POWER

208/230 1Ø

BLK

BRN

OFM

*SC

*SR

BLU

YEL

CAP

BLK

COMP

YEL

BLK

BLK

*CH

BLK

BLU

DR

OF1

OF2

CY OW2R

LOGIC

Y

T1

LOGIC

T2

60

90

120

30

SPEED

UP

R

C

C

DFT

O

BRN

YEL

CESO130076-01

CTD

ORG

ORG

or

RVS

BLK

BLK

DFT

BLK

or

PNK

PNK

BLK

ORG

ORG

or

PNK

or

PNK

+t°

*ST

*CHS

*CH

23

R

C

S

5

2

1

LOGIC

LOGIC

C

CONT

T2

CTD

T1

C

*HPS

*LPS

Y

Y

DFT

DFT

C

RVS

R

R

W2

O

O

OF1 OF2

DR

L2

23

CONT

OFM

CAP

F

C

COMP

H

*SC

*SR

21

11

L1

CONT

RVSR

AUXR

RVSR

AUXR

GND

EQUIP

2

Loading...

Loading...