-->

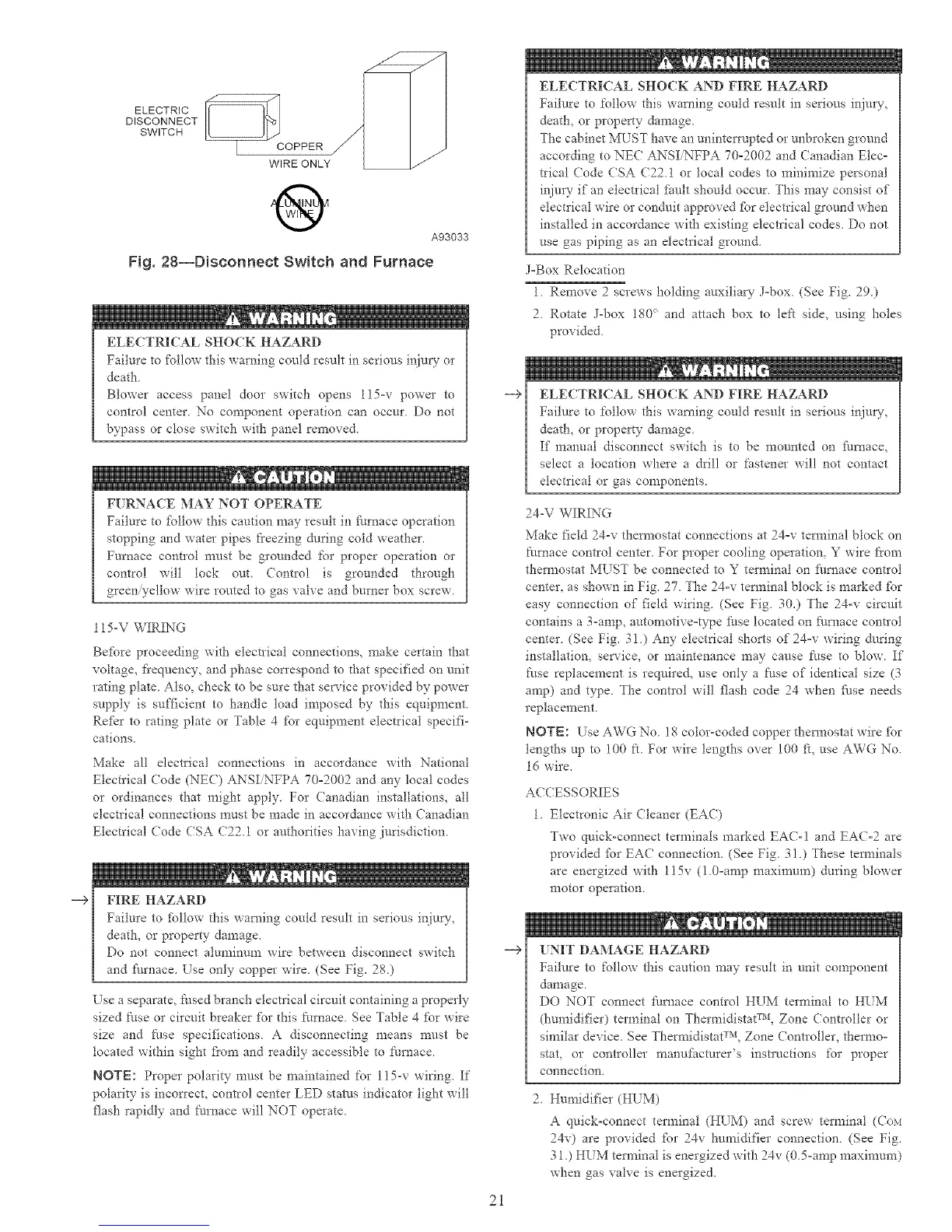

ELECTRIC

DISCONNECT

SWITCH

®

A93033

Fig. 28--Disconnect Switch and Furnace

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in serious injury or

death.

Blower access panel door switch opens l15=v power to

control center No component operation can occur Do not

bypass or close switch with panel removed

FURNACE MAY NOT OPERATE

Failure 6o fbllow this caution may result in furnace operation

stopping and water pipes freezing during cold weather.

Furnace control must be grounded for proper operation or

control will lock out. Control is grounded through

green yellow wire routed to gas valve and burner box screw

115-V WIRING

Before proceeding with electrical connections, make certain that

voltage, fiequency, and phase con'espond to d-_at specified on unit

rating plate Also, check to be sure that service provided by power

supply is sufficient to handle toad imposed by this equipment.

Re_kr to rating plate or Table 4 for equipment electrical specifi-

cations.

Make all electrical connections in accordance with National

Electrical Code (NEE) ANSIiNFPA 70°2002 and any local codes

or ordinances that might apply For Canadian installations, all

electrical connections must be made in accordance with Canadian

Electrical (:ode CSA (722.1 or authorities having jurisdiction.

FIRE HAZARD

Failure to _bllow this warning could result in serious injury,

death, or property damage.

Do not connect aluminum wire between disconnect switch

and f_/rnace. Use only copper wire (See Fig. 28)

"Use a separate, fused branch electrical circuit containing a properly

sized fuse or circuit breaker for this furnace See Table 4 _k_rwire

size and filse specifications. A disconnecting means must be

located within sight fiom and readily accessible to furnace

NOTE: Proper polarity must be maintained for 115-v wiring. If

polarity is incorrect, control center LED status indicator light will

flash rapidly and I:umace will NOT operate.

-->

-->

2i

ELECTRICAL SHOCK AND FIRE HAZARD

Failure to follow this warning could result in serions inju U,

death, or property damage.

The cabinet MUST have an uninterrupted or unbroken ground

according to NEC ANSI NFPA 70°2002 and Canadian Elec=

tdcal (7ode CSA (22.1 or local codes to minimize personal

injm T if an electrical fhult should occur. This may consist of

electrical wire or condtlit approved for electrical ground when

installed in accordance with existing electrical codes. Do not

use gas piping as an electrical ground.

J=Box Relocation

1. Remove 2 screws holding auxiliary- J=box. (See Fig. 29.)

2 Rotate J-box 180 _>and attach box to left side, using holes

provided

ELECTRICAL SHOCK AND FIRE HAZARD

Failure to follow this warning could result in serions inju W,

death, or property damage

If manual disconnect switch is to be mounted on fimaace,

select a location where a drill or Pastener will not contact

electrical or gas components.

24-V WIRING

Make field 24-v them_ostat connections at 24°v terminal block on

furnace control center For proper cooling operation, Y wire from

thermostat MUST be connected to Y terminal on [ku_aace control

center, as shown in Fig. 27. The 24=v terminal block is marked fbr

easy connection of field wiring. (See Fig 30.) The 24-v circuit

contains a 3=amp, automotive=type fuse located on fk/rnace control

center (See Fig. 31) Any electrical shorts of 24=v wiring dnring

installation, service, or maintenance may cause litse to blow If

fuse replacement is required, use only a fuse of identical size (3

amp) and type The control will flash code 24 when _k/se needs

replacement

NOTE: Use AWG No 18 color-coded copper them_ostat wire fbr

lengths up to 100 ft For wire lengths over 100 _, use AWG No.

1d wire.

ACCESSORIES

1 Electronic Air Cleaner (EAC)

Two quickoconnect terminals marked EAC-I and EA(=2 are

provided _br EAC connection. (See Fig. 31 ) These tem_inals

are energized with 115v (i 0=amp maximnm) during blower

motor operation.

UNIT DAMAGE HAZARD

Failure to follow this caution may result in unit component

damage

DO NOT connect f_arnace control HUM terminal to HI_M

(humidifier) terminal on Thermidistat TM, Zone Controller or

similar device. See Thermidistat TM, Zone (ontloller, thernao=

stat, or controller manu_itcturer's instructions for proper

connection,

2 Humidifier (HUM)

A quick°connect terminal (HUM) and screw terminal (Cox1

24v) are provided for 24v humidifier connection (See Fig.

31,) HUM tem_inal is energized with 24v (0 5-amp n_axin_un_)

when gas valve is energized,

Loading...

Loading...