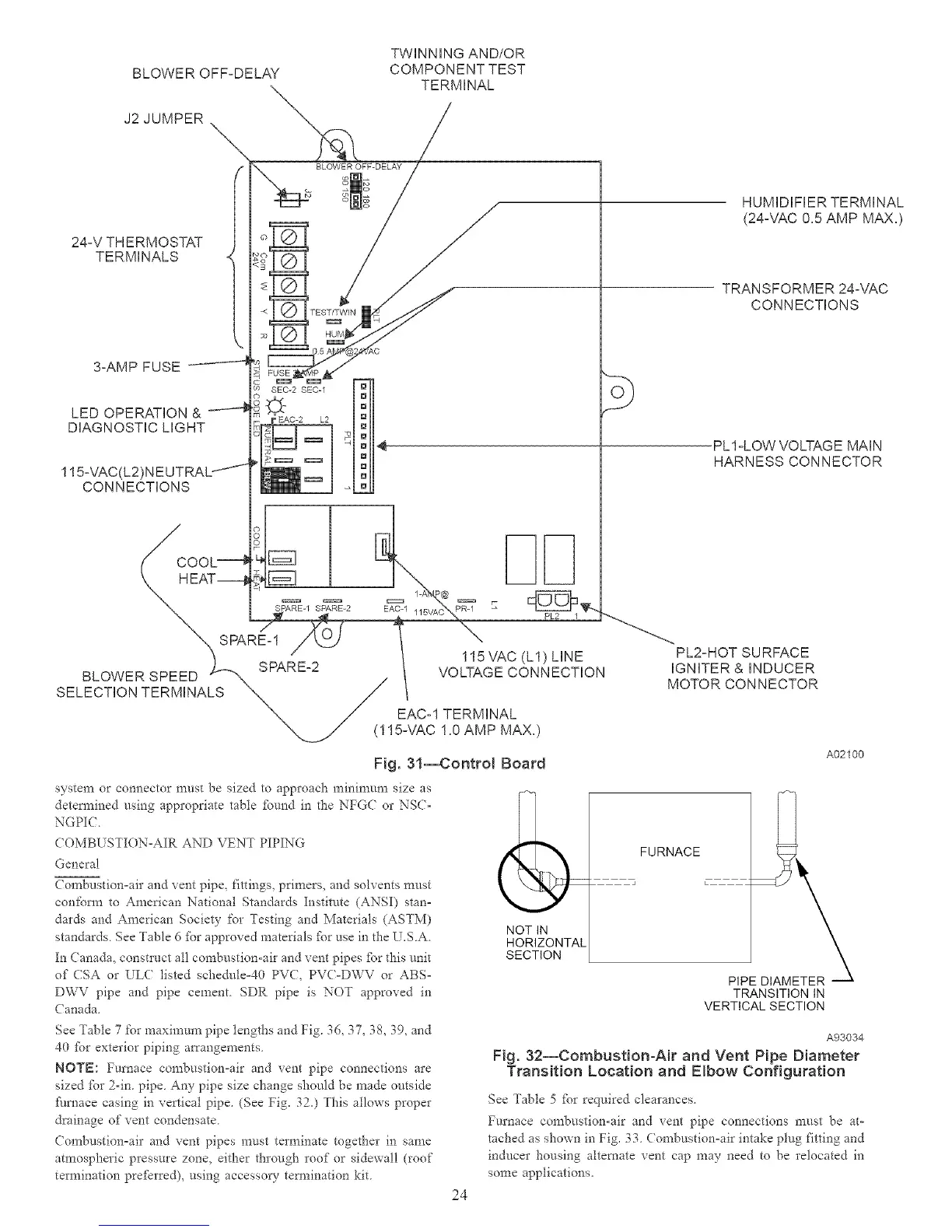

BLOWER OFF-DELAY

J2 JUMPER

TWiNNiNG AND/OR

COMPONENT TEST

TERMINAL

24-V TH ERMOSTAT

TERMINALS

3-AMP FUSE

LED OPERATION &

DiAGNOSTiC LIGHT

115-VAC(L2)N EUTRAL --'11

CONNECTIONS

SEC-2 8EC-1

HUMiDIFiER TERMINAL

(24-VAC 0.5 AMP MAX.)

TRANSFORMER 24-VAC

CONNECTIONS

ob

PL1-LOW VOLTAGE MAiN

HARNESS CONNECTOR

SELECTION TERMINALS

PL2-HOT SURFACE

VOLTAGE CONNECTION IGNITER & INDUCER

_./ EAC-1 TERMINAL

MOTOR CONNECTOR

15AiAC 1.0 AMP MAX.)

Fig. 31--Control Board

A02100

system or connector must be sized to approach minimum size as

detem_ined using appropriate table fbund in the NFG( or NSC°

NGPIC.

COMBUSTION=AIR AND VENT PIPING

General

Combustion°air and vent pipe, fittings, primers, and solvents must

confom_ to American National Standards Institute (ANSI) stan=

dards and American Socie w for Testing and Materials (ASTM)

standards See Table (5fbr approved materials fPr use in the U.SA

In (anada, constluct all combustion-aft and vent pipes fbr this unit

of (SA or ULC listed schedule40 PV(, PVC°DWV or ABS°

DWV pipe and pipe cement SDR pipe is NO7 approved in

( anada.

(

NOT IN

HORIZONTAL

SECTION

FURNACE

TRANSITION IN

VERTICAL SECTION

See Table 7 for maximum pipe lengths and Fig. 36, 37, 38, 39, and

40 fbr exterior piping an'angements

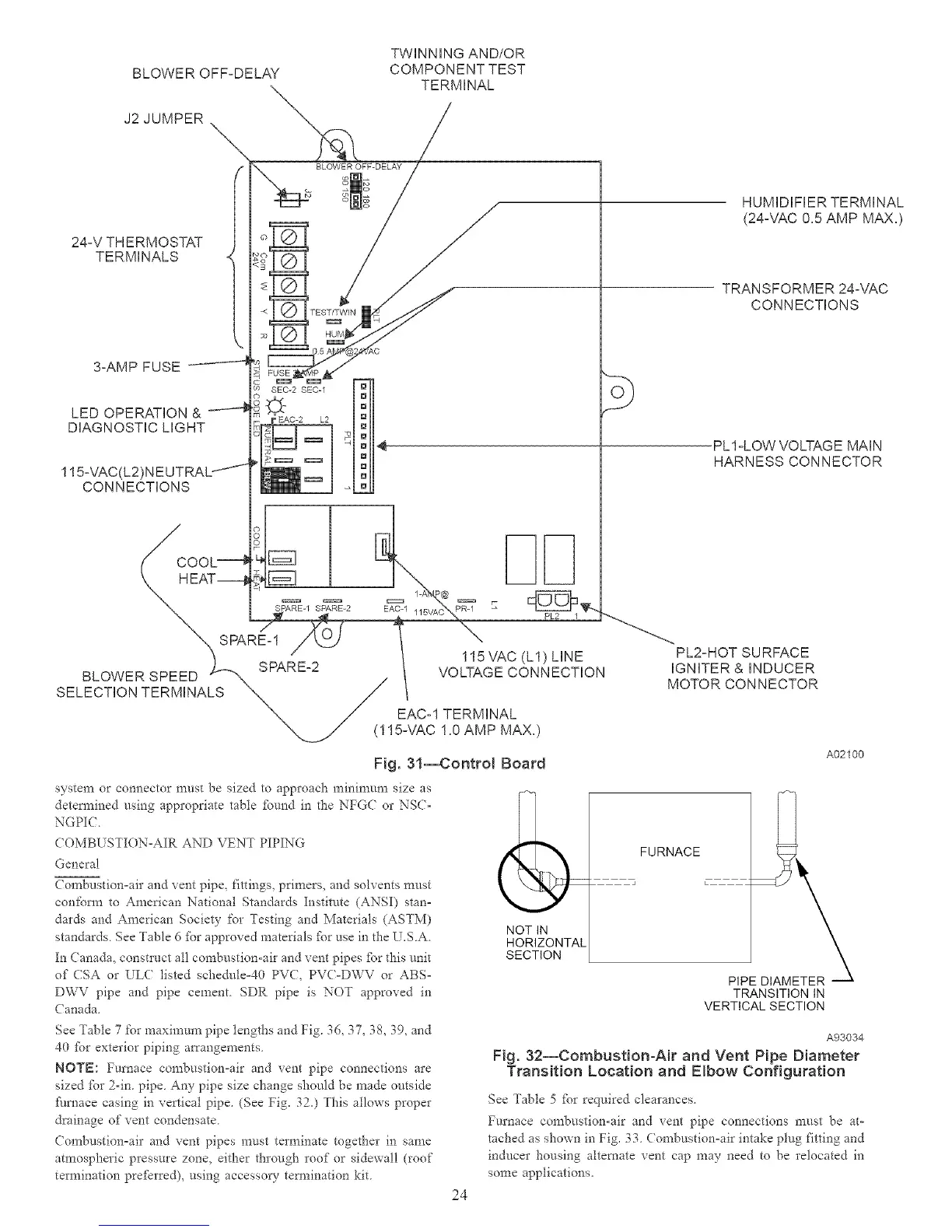

NOTE: Fm'nace combustion°air and vent pipe connections are

sized fbr 2-in. pipe. Any pipe size change should be made outside

furnace casing in vertical pipe. (See Fig. 320 This allows proper

drainage of vent condensate.

Combustion=air and vent pipes must terminate together in same

atmospheric pressure zone, either through roof or sidewall (roof

termination prefBrred), using accessory tem_ination kit.

24

A93034

Fig. 32--Combustion-Air and Vent Pipe Diameter

Transition Location and Elbow Configuration

See Table 5 %r required clearances

Furnace combustion-air and vent pipe connections must be at-

tached as shown in Fig. 33 (ombustion=air intake plug fitting and

inducer housing alternate vent cap may need to be relocated in

some applications.

Loading...

Loading...