1002-4

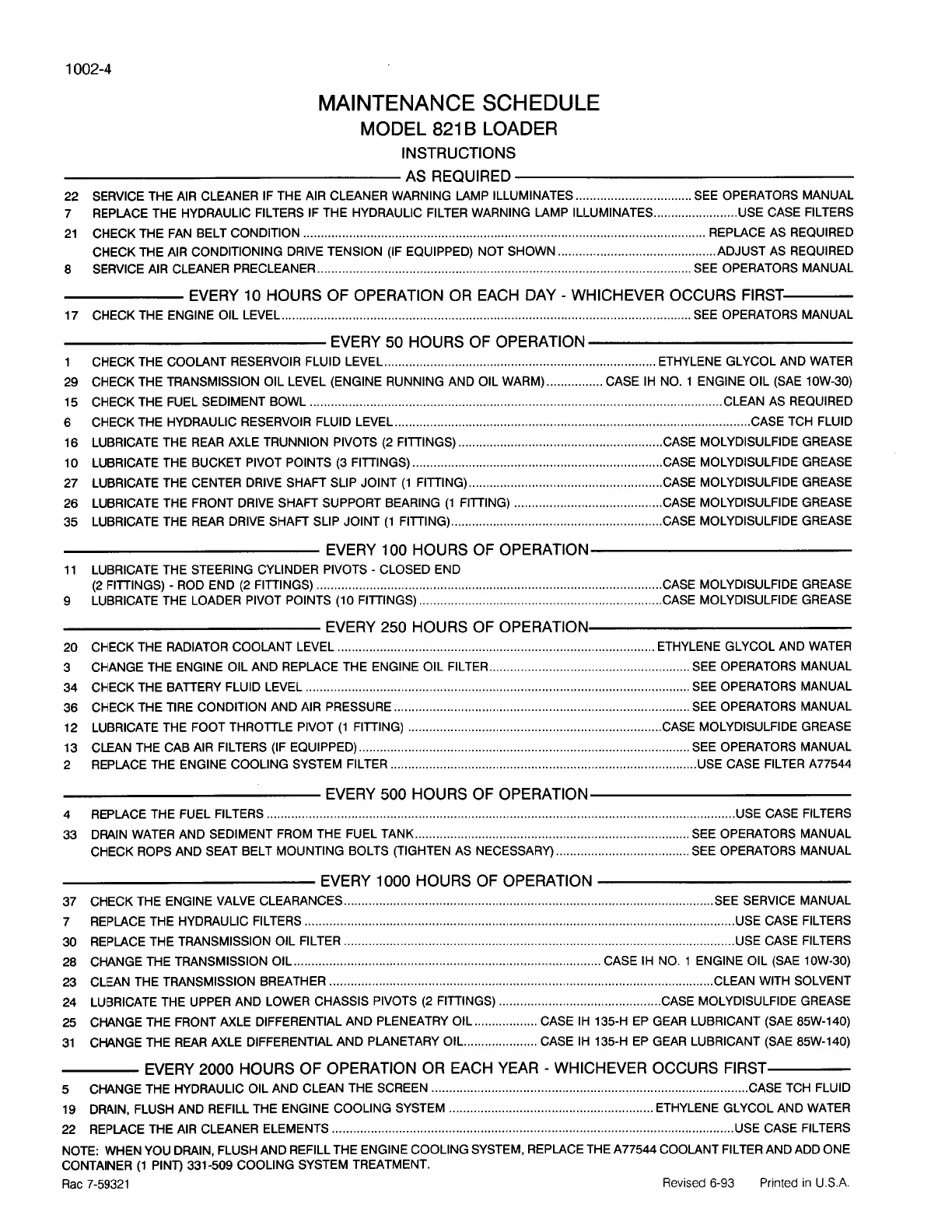

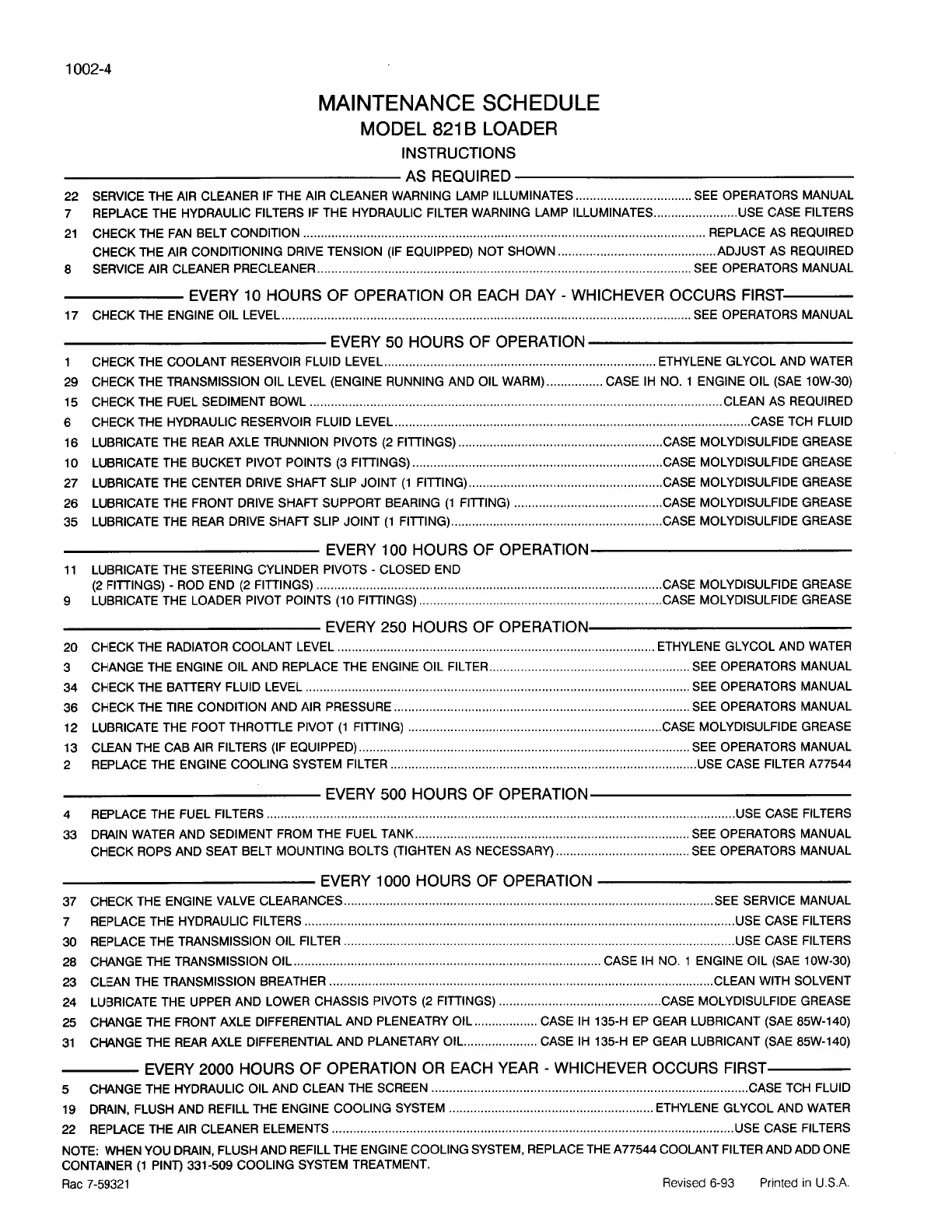

MAINTENANCE SCHEDULE

MODEL

821

B LOADER

INSTRUCTIONS

----------------AS

REQUIRED----------------

22 SERVICE THE

AIR

CLEANER IF THE AIR CLEANER WARNING LAMP ILLUMINATES ................................. SEE OPERATORS MANUAL

7 REPLACE THE HYDRAULIC FILTERS IF THE HYDRAULIC FILTER WARNING LAMP ILLUMINATES ........................ USE CASE FILTERS

21

CHECK THE

FAN

BELT CONDITION .................................................................................................................. REPLACE

AS

REQUIRED

CHECK THE

AIR

CONDITIONING DRIVE TENSION (IF EQUIPPED) NOT SHOWN ............................................. ADJUST

AS

REQUIRED

8 SERVICE AIR CLEANER

PRE

CLEANER .......................................................................................................... SEE OPERA TORS MANUAL

-----

EVERY

10

HOURS OF OPERATION

OR

EACH

DAY

- WHICHEVER OCCURS

FIRST---

11 CHECK THE ENGINE OIL LEVEL .................................................................................................................... SEE OPERA TORS MANUAL

------------EVERY

50

HOURS

OF

OPERATION------------

1 CHECK THE COOLANT RESERVOIR FLUID LEVEL.. ........................................................................... ETHYLENE GLYCOL AND WATER

29 CHECK THE TRANSMISSION OIL LEVEL (ENGINE RUNNING AND OIL WARM) ................ CASE

IH

NO. 1 ENGINE OIL (SAE 10W-30)

15 CHECK THE FUEL SEDIMENT BOWL ..................................................................................................................... CLEAN

AS

REQUIRED

6 CHECK THE HYDRAULIC RESERVOIR FLUID LEVEL. .................................................................................................... CASE

TCH

FLUID

16 LUBRICATE THE

REAR

AXLE TRUNNION PIVOTS

(2

FITTINGS) .......................................................... CASE MOLYDISULFIDE GREASE

10 LUBRICATE THE BUCKET PIVOT POINTS (3 FITTINGS) ....................................................................... CASE MOLYDISULFIDE GREASE

27 LUBRICATE THE CENTER DRIVE SHAFT SLIP JOINT

(1

FITTING) ....................................................... CASE MOLYDISULFIDE GREASE

26 LUBRICATE THE FRONT DRIVE SHAFT SUPPORT BEARING

(1

FITTING) .......................................... CASE MOLYDISULFIDE GREASE

35 LUBRICATE THE

REAR

DRIVE SHAFT SLIP JOINT

(1

FITTING) ............................................................ CASE MOLYDISULFIDE GREASE

-----------

EVERY

100

HOURS

OF

OPERATION------------

11

LUBRICATE THE STEERING CYLINDER PIVOTS - CLOSED END

(2

FITTINGS) -

ROD

END

(2

FITTINGS) .................................................................................................. CASE MOL YDISULFIDE GREASE

9 LUBRICATE THE LOADER PIVOT POINTS (10 FITTINGS) ..................................................................... CASE MOLYDISULFIDE GREASE

------------

EVERY

250

HOURS

OF

OPERATION------------

20 CHECK THE RADIATOR COOLANT LEVEL .......................................................................................... ETHYLENE GLYCOL AND WATER

3 CHANGE THE ENGINE OIL AND REPLACE THE ENGINE OIL FILTER ......................................................... SEE OPERATORS MANUAL

34 CHECK THE BATTERY FLUID LEVEL ............................................................................................................. SEE OPERATORS MANUAL

36 CHECK THE

TIRE

CONDITION AND AIR PRESSURE .................................................................................... SEE OPERATORS MANUAL

12 LUBRICATE THE FOOT THROTTLE PIVOT

(1

FITTING) ........................................................................ CASE MOLYDISULFIDE GREASE

13 CLEAN THE CAB AIR FILTERS (IF EQUIPPED) .............................................................................................. SEE OPERATORS MANUAL

2 REPLACE THE ENGINE COOLING SYSTEM FILTER ....................................................................................... USE CASE FILTER A77544

------------

EVERY

500

HOURS

OF

OPERATION------------

4 REPLACE THE FUEL FILTERS ..................................................................................................................................... USE CASE FILTERS

33 DRAIN WATER AND SEDIMENT FROM THE FUEL TANK .............................................................................. SEE OPERATORS MANUAL

CHECK ROPS AND SEAT BELT MOUNTING BOLTS (TIGHTEN

AS

NECESSARY) ...................................... SEE OPERATORS MANUAL

-----------

EVERY

1000

HOURS

OF

OPERATION-----------

37 CHECK THE ENGINE VALVE CLEARANCES ......................................................................................................... SEE SERVICE MANUAL

7 REPLACE THE HYDRAULIC FILTERS .......................................................................................................................... USE CASE FILTERS

30 REPLACE THE TRANSMISSION OIL FILTER ............................................................................................................... USE CASE FILTERS

28 CHANGE THE TRANSMISSION OIL.. ..................................................................................... CASE

IH

NO. 1 ENGINE OIL (SAE 10W-30)

23 CLEAN THE TRANSMISSION BREATHER ............................................................................................................. CLEAN WITH SOLVENT

24 LUBRICATE THE UPPER AND LOWER CHASSIS PIVOTS

(2

FITTINGS) .............................................. CASE MOLYDISULFIDE GREASE

25 CHANGE THE FRONT AXLE DIFFERENTIAL AND PLENEATRY OIL.. ................ CASE

IH

135-H

EP

GEAR LUBRICANT (SAE 85W-140)

31

CHANGE THE

REAR

AXLE DIFFERENTIAL AND PLANETARY OIL. .................... CASE

IH

135-H

EP

GEAR LUBRICANT (SAE 85W-140)

----

EVERY

2000

HOURS OF OPERATION

OR

EACH

YEAR

- WHICHEVER OCCURS

FIRST----

5 CHANGE THE HYDRAULIC OIL AND CLEAN THE SCREEN .......................................................................................... CASE TCH FLUID

19 DRAIN, FLUSH AND REFILL THE ENGINE COOLING SYSTEM .......................................................... ETHYLENE GLYCOL AND WATER

22 REPLACE THE

AIR

CLEANER ELEMENTS .................................................................................................................. USE CASE FILTERS

NOTE: WHEN YOU DRAIN, FLUSH AND REFILL THE ENGINE COOLING SYSTEM, REPLACE THE A77544 COOLANT FILTER AND ADD ONE

CONTAINER

(1

PINT) 331-509 COOLING SYSTEM TREATMENT.

Rae

7-59321

Revised

6-93

Printed

in

U.S.A.

Loading...

Loading...