22-10

CYLINDER HEAD AND COMPONENTS (Continued)

Inspection

Replace all gaskets, seals and worn or defective parts.

1. Clean the top surface of the block and

sleeve flange carefully. All traces of

carbon and other deposits must be re-

moved. During cleaning, the use of a rag

dampened in solvent is recommended.

2. Using extreme care not to scratch sur-

faces. Remove any small burrs in the

areas to be measured so accurate read-

ings can be obtained.

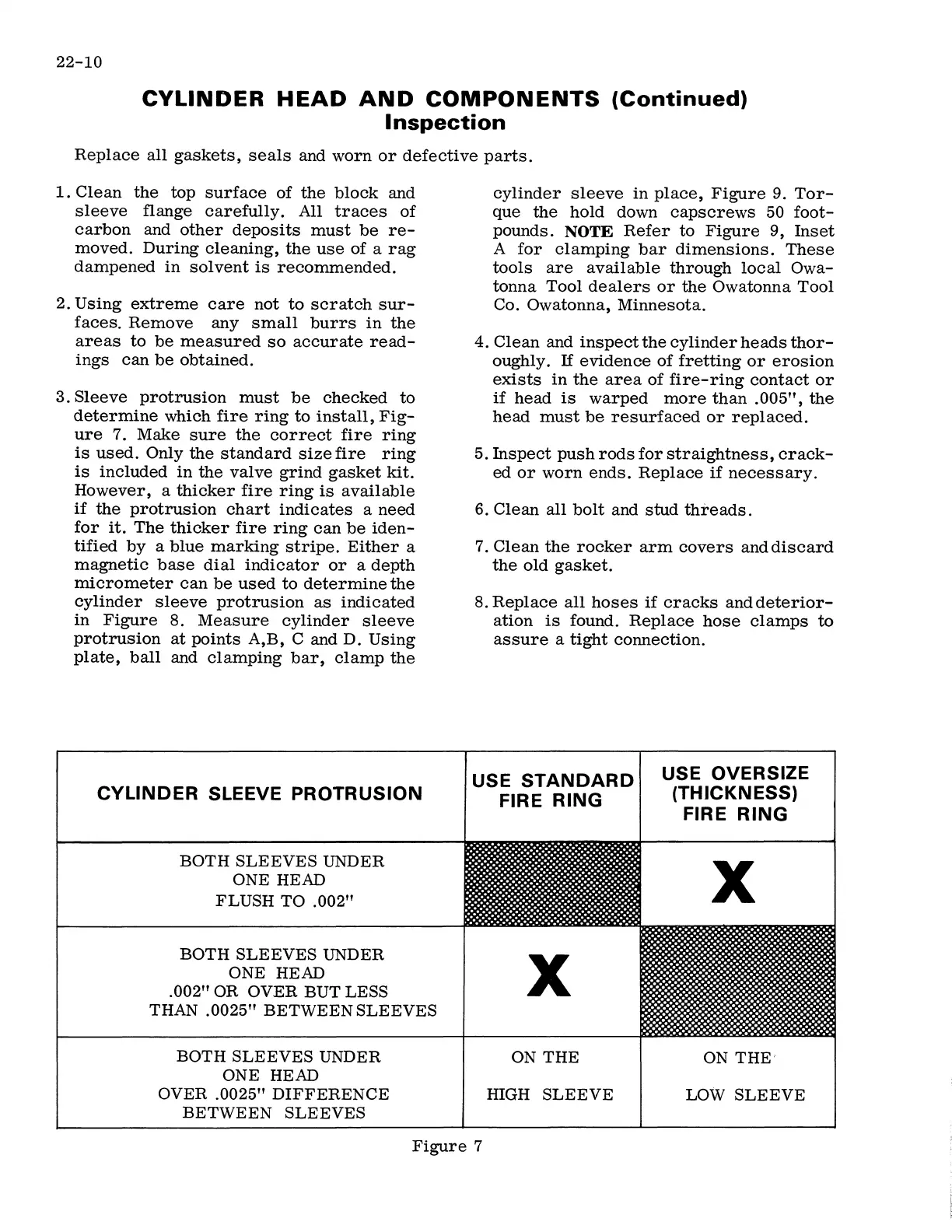

3. Sleeve protrusion must be checked to

determine which fire ring to install, Fig-

ure 7. Make sure the correct fire ring

is used. Only the standard size fire ring

is included in the valve grind gasket kit.

However, a thicker fire ring is available

if the protrusion chart indicates a need

for it. The thicker fire ring can be iden-

tified by a blue marking stripe. Either a

magnetic base dial indicator or a depth

micrometer can be used to determine the

cylinder sleeve protrusion as indicated

in Figure 8. Measure cylinder sleeve

protrusion at points A,B, C and D. Using

plate, ball and clamping bar, clamp the

CYLINDER SLEEVE PROTRUSION

BOTH SLEEVES UNDER

ONE HEAD

FLUSH TO .002"

BOTH SLEEVES UNDER

ONE HEAD

.002" OR OVER BUT LESS

THAN .0025" BETWEEN SLEEVES

BOTH SLEEVES UNDER

ONE HEAD

OVER .0025" DIFFERENCE

BETWEEN SLEEVES

cylinder sleeve in place, Figure 9. Tor-

que the hold down capscrews 50 foot-

pounds.

NOTE Refer to Figure 9, Inset

A for clamping bar dimensions. These

tools are available through local Owa-

tonna Tool dealers or the Owatonna Tool

Co. Owatonna, Minnesota.

4. Clean and inspect the cylinder heads thor-

oughly. If evidence of fretting or erosion

exists in the area of fire-ring contact or

if head is warped more than .005", the

head must be resurfaced or replaced.

5. Inspect push rods for straightness, crack-

ed or worn ends. Replace if necessary.

6. Clean all bolt and stud threads.

7. Clean the rocker arm covers and discard

the old gasket.

8. Replace all hoses if cracks and deterior-

ation is found. Replace hose clamps to

assure a tight connection.

USE STANDARD

FIRE RING

X

ON THE

filGH SLEEVE

USE OVERSIZE

(THICKNESS)

FIRE RING

X

ON THE'

LOW SLEEVE

Figure 7

Loading...

Loading...