22-20

INSPECTION OF VALVES, GUIDES, HEAD AND SPRINGS

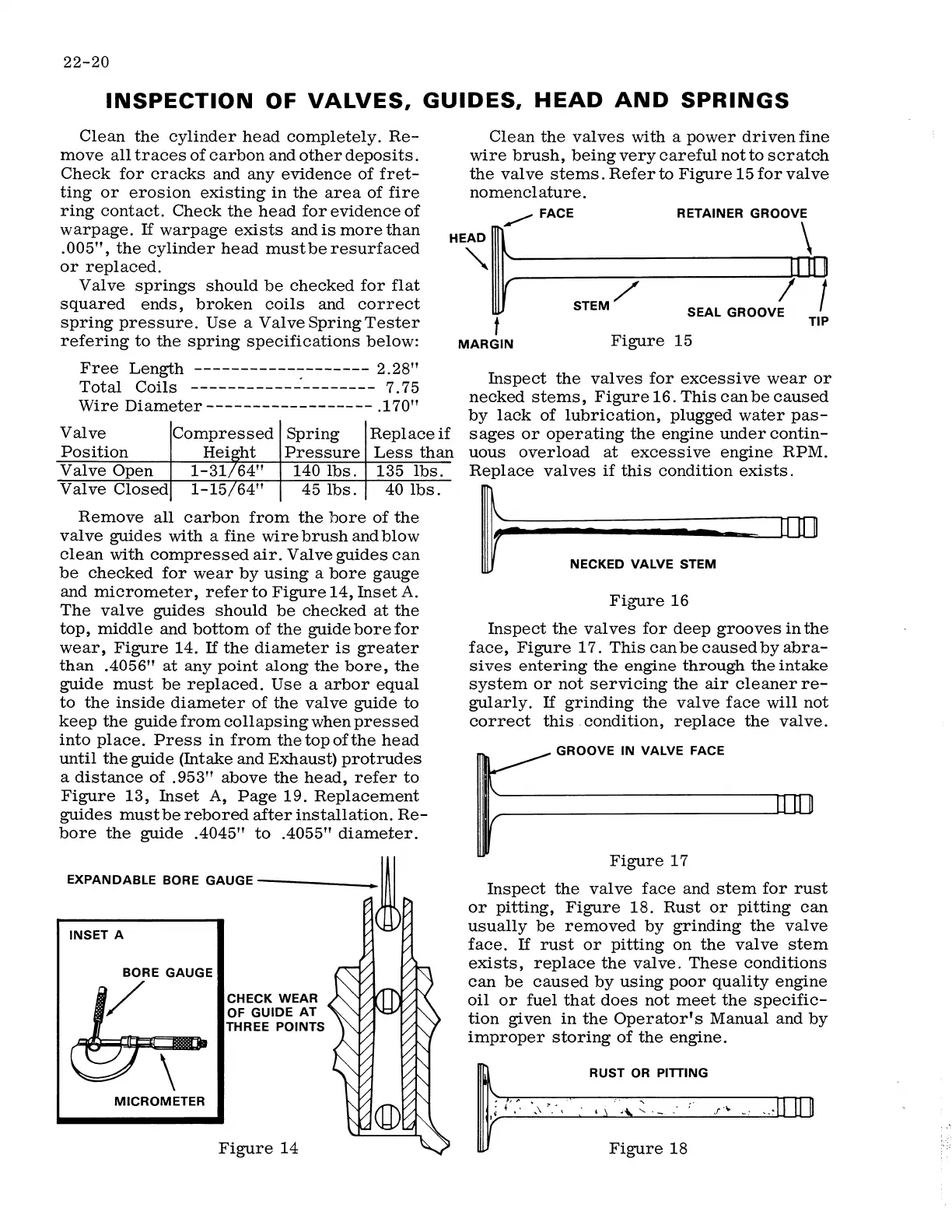

Clean the valves with a power driven fine

wire brush, being very careful not to scratch

the valve stems. Ref er

to Figure 15 for valve

nomenclature.

Clean the cylinder head completely. Re-

move all traces of carbon and other deposits.

Check for cracks and any evidence of fret-

ting or erosion existing in the area of fire

ring contact. Check the head for evidence of

warpage.

If warpage exists and is more than

.005", the cylinder head mustberesurfaced

or replaced.

Valve springs should be checked for flat

squared ends, broken coils and correct

spring pressure. Use a ValveSpringTester

refering to the spring specifications below:

H~t~--F-A_C_E ______ R_E_T_A_I_N-ER_G_R_O_O~V~'~

"" _

ID

□

STEM/ SEAL GROOV( /

Free Length ------------------- 2.28"

Total Coils ___________ _: ________ 7. 75

Wire Diameter------------------ .170"

Valve

Compressed Spring

Replace

if

Position

Heisrht Pressure Less than

Valve Open

1-31/64"

140 lbs.

135 lbs.

Valve Closed

1-15/64"

45 lbs.

40 lbs.

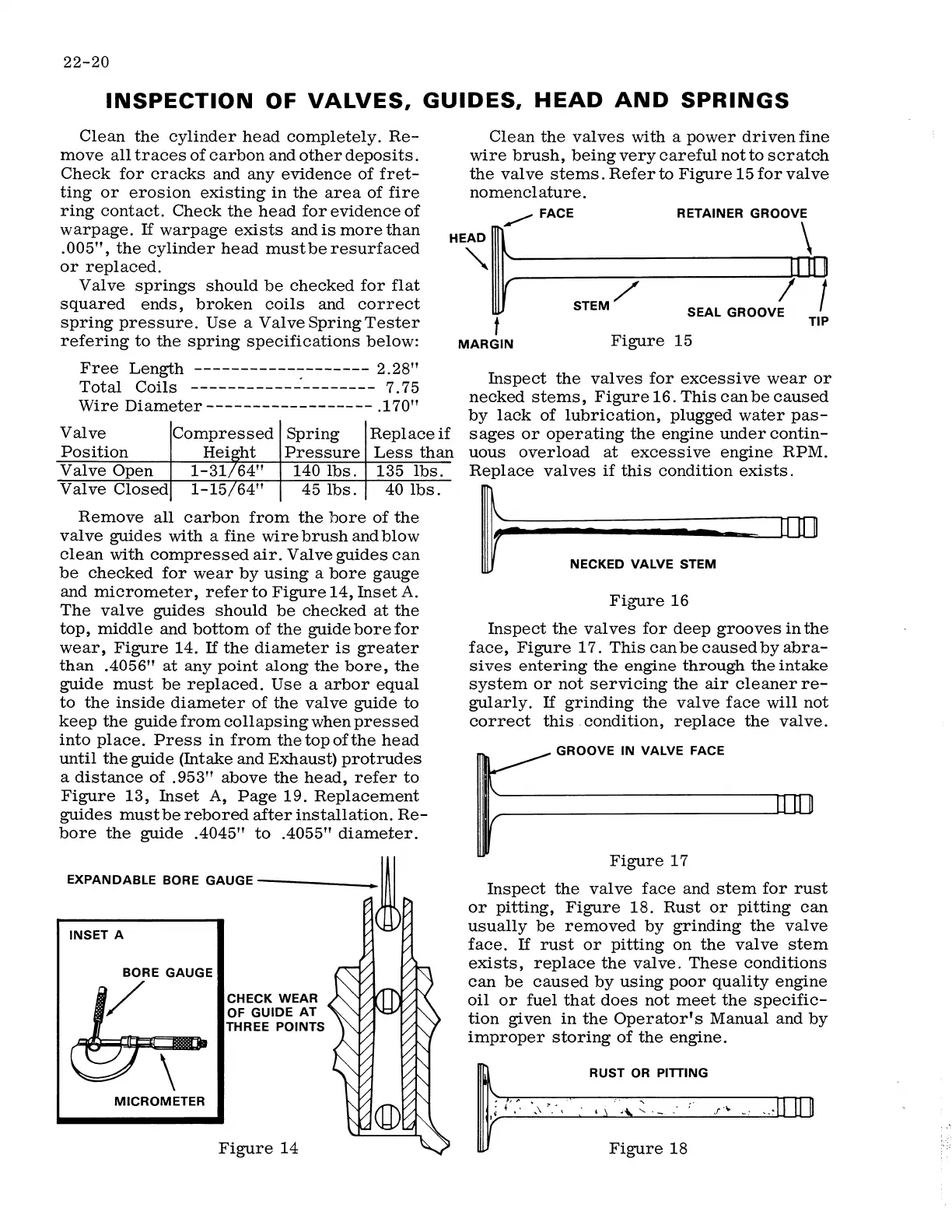

Remove all carbon from the bore of the

valve guides with a fine wire brush and blow

clean with compressed air. Valve guides can

be checked for wear by using a bore gauge

and micrometer, refer to Figure 14, Inset A.

The valve guides should be checked at the

top, middle and bottom of the guide bore for

wear, Figure 14.

If the diameter is greater

than .4056" at any point along the bore, the

guide must be replaced. Use a arbor equal

to the inside diameter of the valve guide to

keep the guide from collapsing when pressed

into place. Press in from the top of the head

until the guide (Intake and Exhaust) protrudes

a distance of .953" above the head, refer to

Figure 13, Inset A, Page 19. Replacement

guides must be rebored after installation. Re-

bore the guide .4045" to .4055" diameter.

EXPANDABLE BORE GAUGE------

INSET A

BORE GAUGE

1/

MICROMETER

CHECK WEAR

OF GUIDE AT

THREE POINTS

Figure 14

t TIP

Figure 15

MARGIN

Inspect the valves for excessive wear or

necked stems, Figure 16. This can be caused

by lack of lubrication, plugged water pas-

sages or operating the engine under contin-

uous overload at excessive engine RPM.

Replace valves if this condition exists.

l;..;;:;;;;;;;;;;;;;;;;;;;;;;;;;;~;;;;;;;:;;;;:===rrDJIIJ[]

r NECKED VALVE STEM

Figure 16

Inspect the valves for deep grooves in the

face, Figure 17. This can be caused by abra-

sives entering the engine through the intake

system or not servicing the air cleaner re-

gularly.

If grinding the valve face will not

correct this . condition, replace the valve.

GROOVE IN VALVE FACE

Figure 17

Inspect the valve face and stem for rust

or pitting, Figure 18. Rust or pitting can

usually be removed by grinding the valve

face.

If rust or pitting on the valve stem

exists, replace the valve. These conditions

can be caused by using poor quality engine

oil or fuel that does not meet the specific-

tion given in the Operator's Manual and by

improper storing of the engine.

RUST OR PITTING

Figure 18

Loading...

Loading...