22-23

GRINDING INTAKE AND EXHAUST VALVE SEATS

Al ways use a precision seat grinder. Take

very light cuts with the grinding stones so

just enough metal is removed to end up with

a good smooth seat finish.

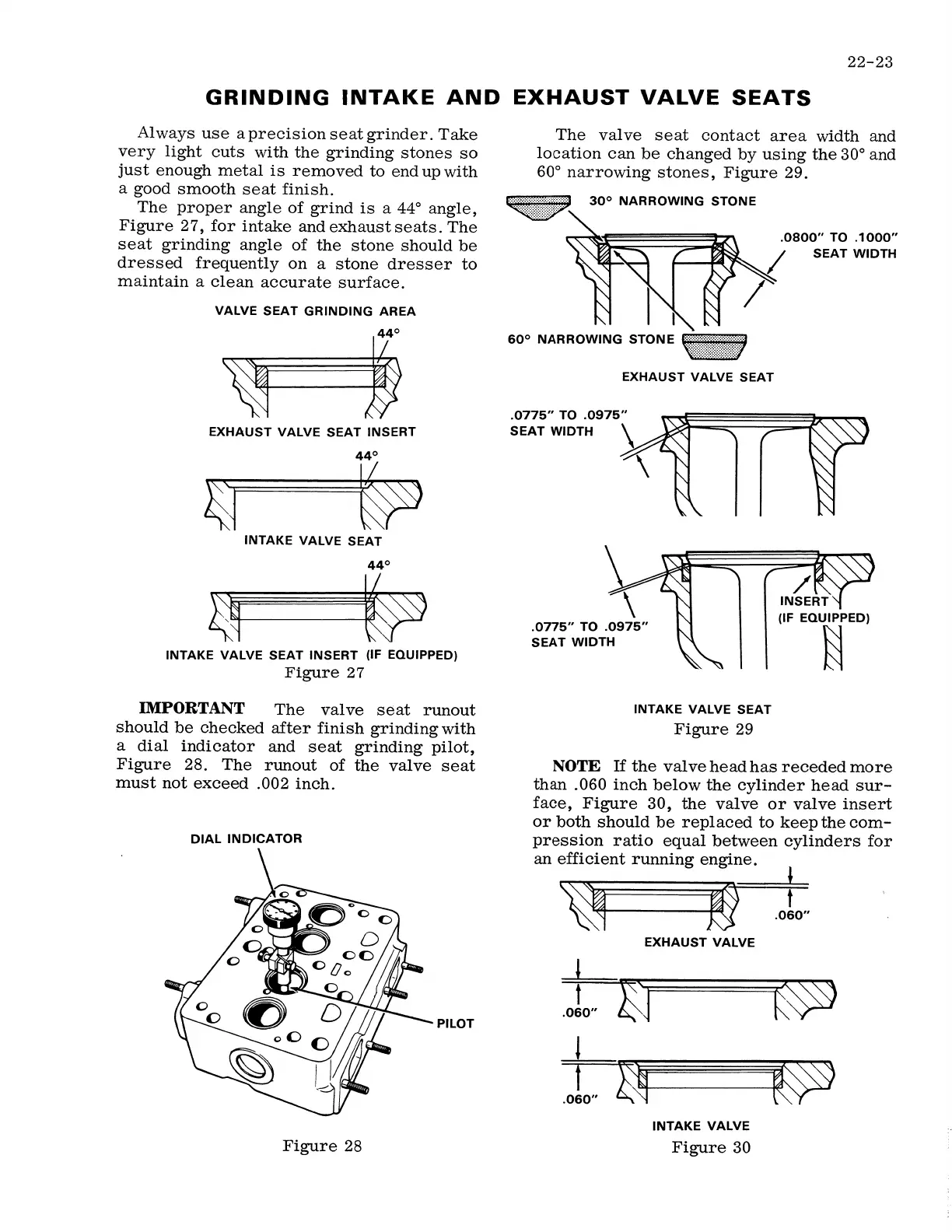

The proper angle of grind is a 44° angle,

Figure 27, for intake and exhaust seats. The

seat grinding angle of the stone should be

dressed frequently on a stone dresser to

maintain a clean accurate surface.

VALVE SEAT GRINDING AREA

EXHAUST VALVE SEAT INSERT

~

INTAKE VALVE SEAT

44°

~---~

INTAKE VALVE SEAT INSERT {IF EQUIPPED)

Figure 27

IMPORTANT

The valve seat runout

should be checked after finish grinding with

a dial indicator and seat grinding pilot,

Figure 28. The runout of the valve seat

must not exceed .002 inch.

DIAL INDICATOR

PILOT

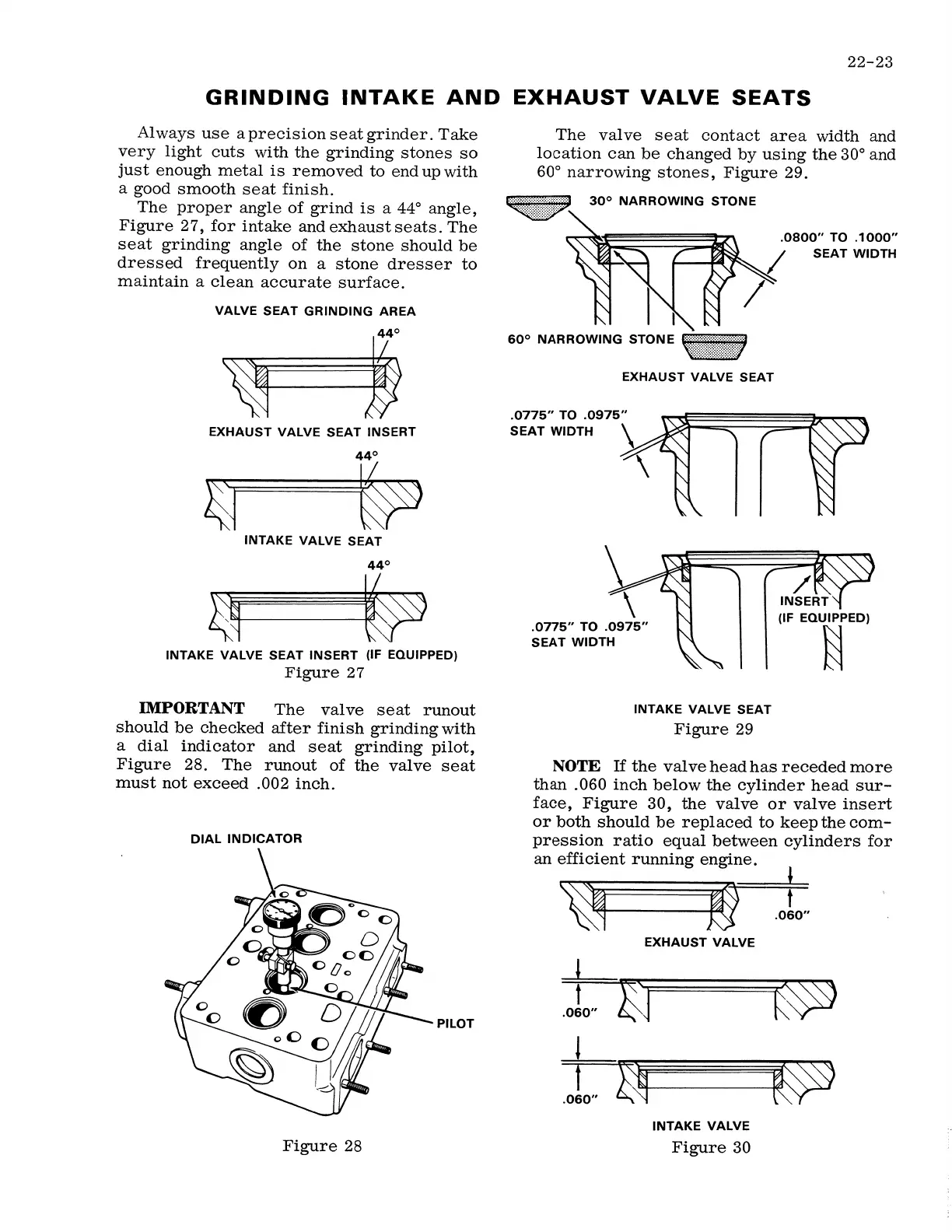

The valve seat contact area width and

location can be changed by using the 30° and

60° narrowing stones, Figure 29.

••':'.';:;:;:::;;::::>'

30° NARROWING STONE

60° NARROWING STONE,,.,.,, .. ,.,.,:::,.,,,

EXHAUST VALVE SEAT

.0775"

TO

.0975"

SEAT WIDTH \

\

.0775"

TO

.0975"

SEAT WIDTH

INTAKE VALVE SEAT

Figure 29

.0800" TO .1000"

SEAT WIDTH

NOTE

If

the valve head has receded more

than .060 inch below the cylinder head sur-

face, Figure 30, the valve or valve insert

or both should be replaced to keep the com-

pression ratio equal between cylinders for

an efficient running engine.

~

t

.060"

EXHAUST VALVE

l

t

.060"

!

t

.060"

INTAKE VALVE

Figure 28 Figure 30

Loading...

Loading...