— 47 —

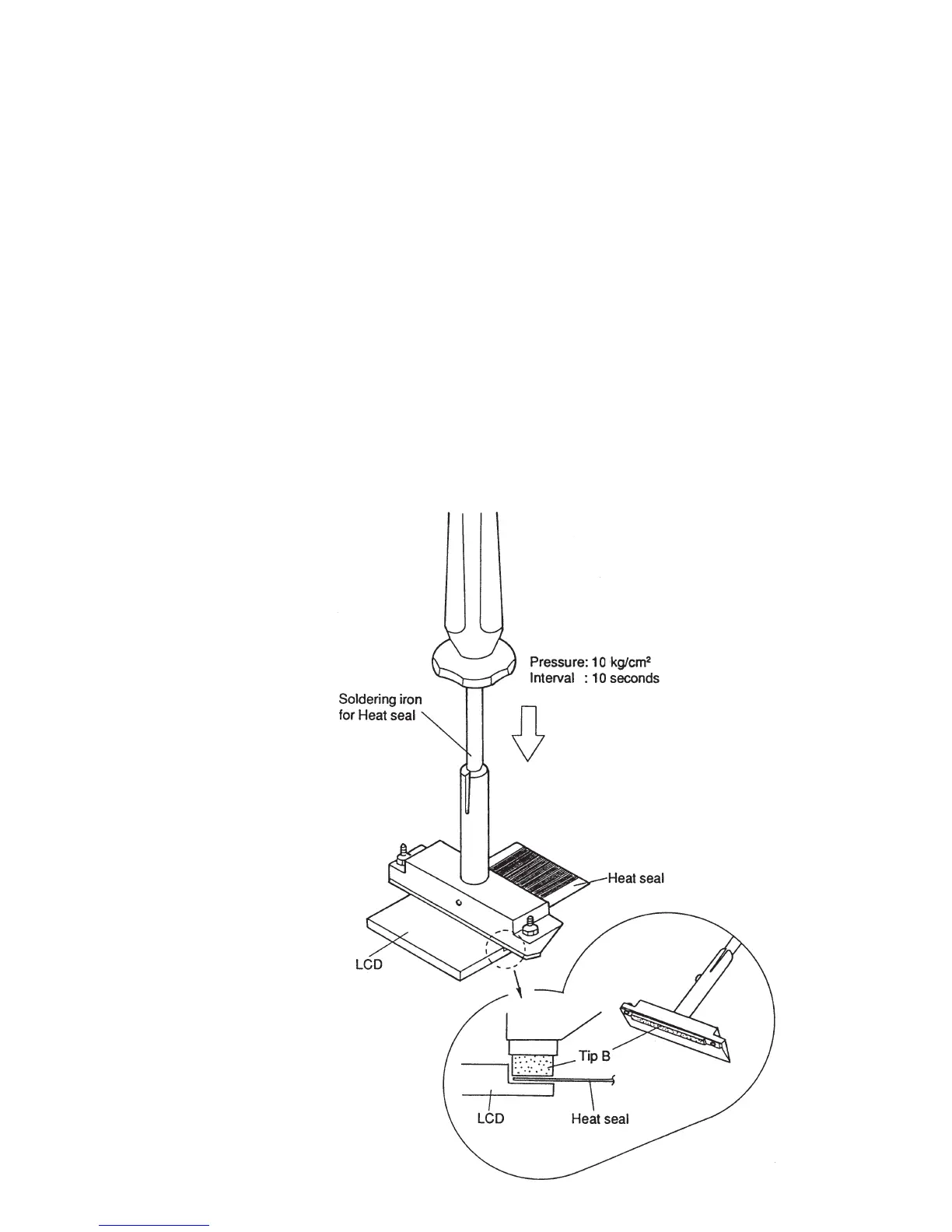

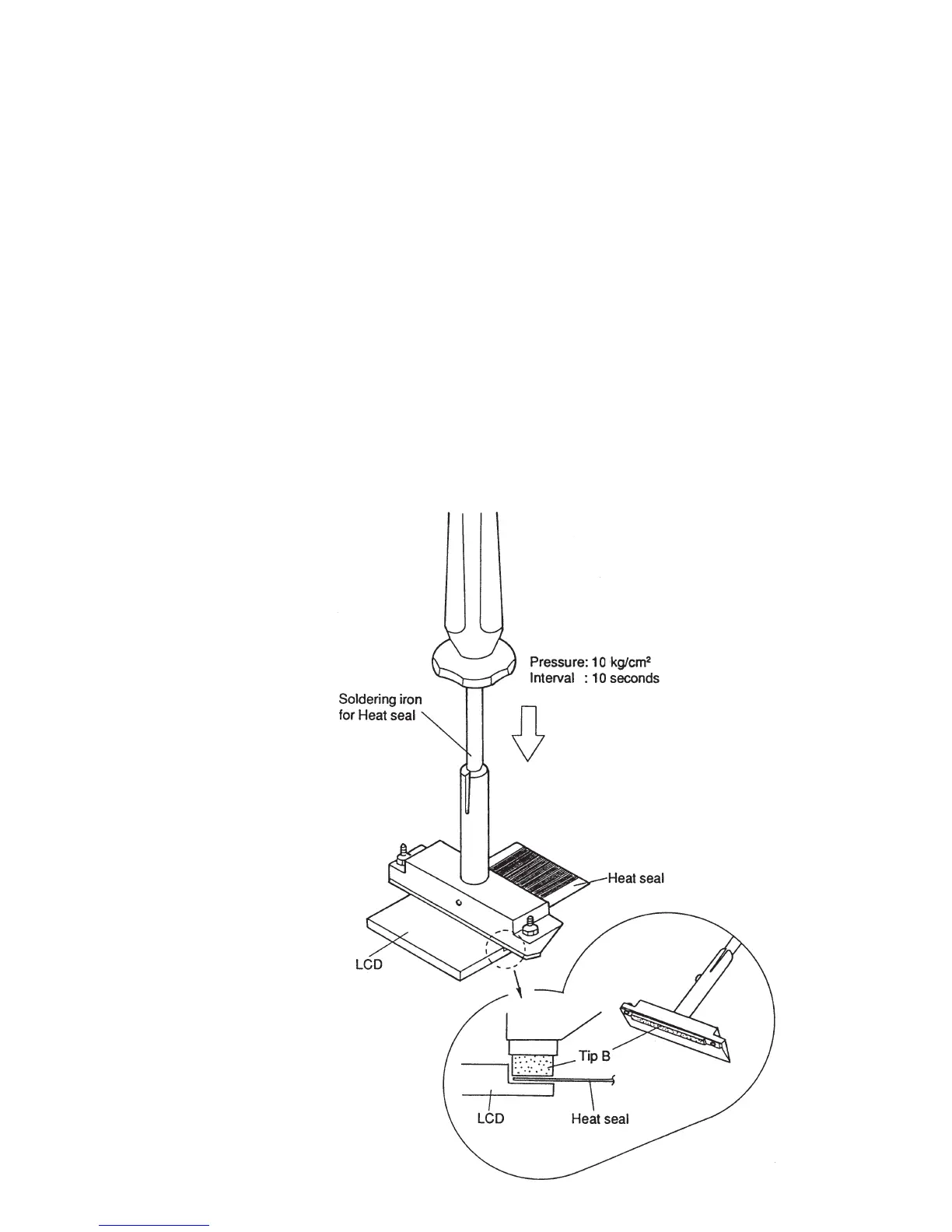

5) On using both silicone rubber and heat seal tip, perform the thermal compression bonding by

touching the soldering iron vertically to heat seal and LCD from upper side as shown in drawing

with following conditions.

Pressure: 10kg/ cm

2

Pressing time: approx. 10 seconds.

Firstly make the bonding at both end to fix the position of the heat seal on LCD, and then make the

bonding to the rest.

6) When the thermal compression bonding is completed, turn the LCD with heat seal and check the

condition of the bonding.

On this time, you can judge the bonding was performed correctly if the bonding part is turned

translucent.

In case the bonding part is not translucent partially, perform the thermal compression bonding

again to such part.

7) Perform the thermal compression bonding of heat seal (with LCD) and P.C.B. ass’y. Though the

bonding way is as same as the one of the heat seal and LCD, perform the thermal compression

bonding until the terminals of the P.C.B. ass’y are float up on the heat seal.

8) When the thermal compression bonding is completed, reassemble them and install the battery to

the clock to check the display.

Fig. 16-2

Loading...

Loading...