78

Maintenance Section

Engine Protective Devices - Check

1. Remove the oil filter with a 1U-8760 Chain

Wrench.

2. Cut the oil filter open with a 4C-5084 Oil Filter

Cutter. Break apart the pleats and inspect the oil

filter for metal debris. An excessive amount of

metal debris in the oil filter may indicate early

wear or a pending failure.

Use a magnet to differentiate between the

ferrous metals and the nonferrous metals that

are found in the oil filter element. Ferrous metals

may indicate wear on the steel and cast iron

parts of the engine.

Nonferrous metals may indicate wear on the

aluminum parts, brass parts or bronze parts of

the engine. Parts that may be affected include

the following items: main bearings, rod bearings,

turbocharger bearings, and cylinder heads.

Due to normal wear and friction, it is not

uncommon to find small amounts of debris in the

oil filter. Consult your Caterpillar dealer in order

to arrange for a further analysis if an excessive

amount of debris is found in the oil filter.

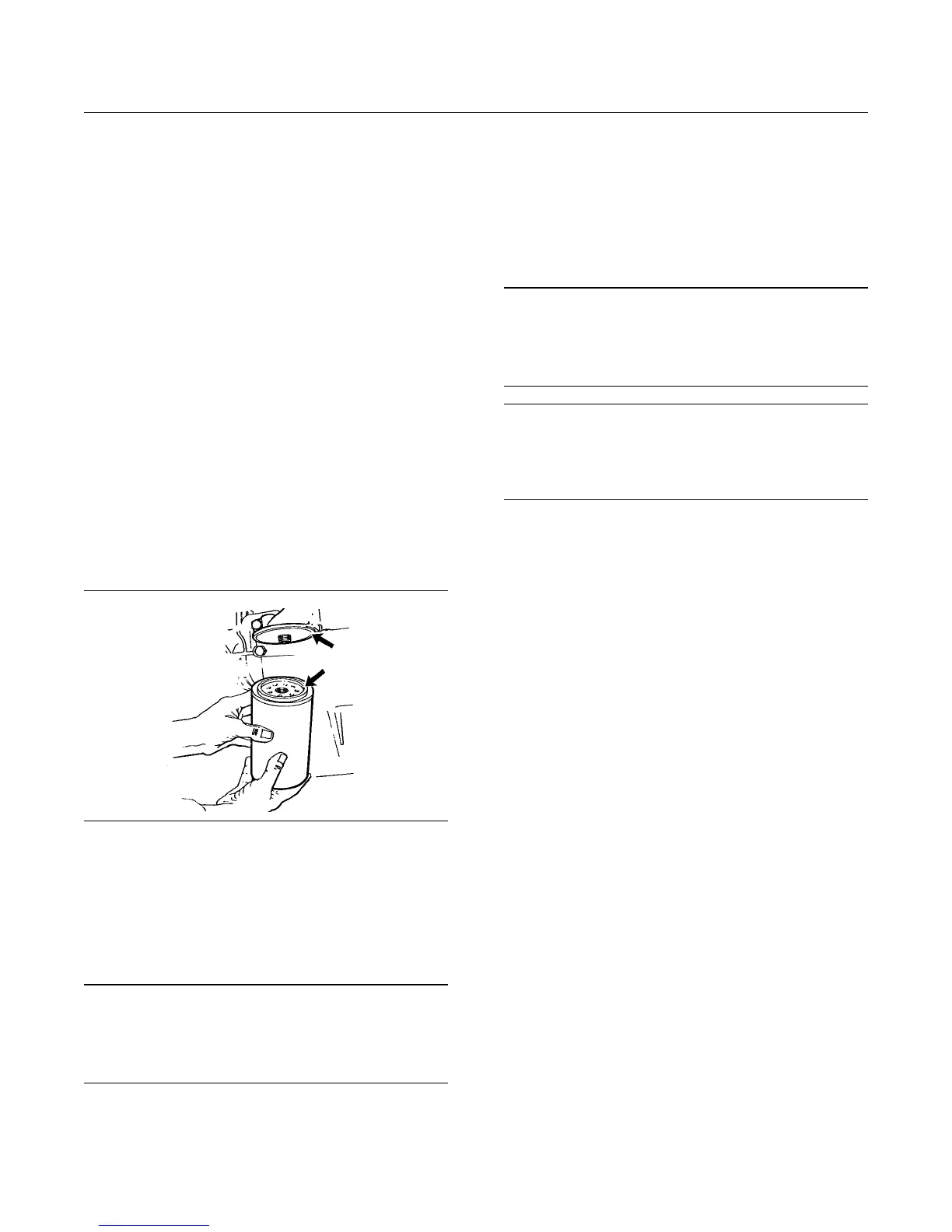

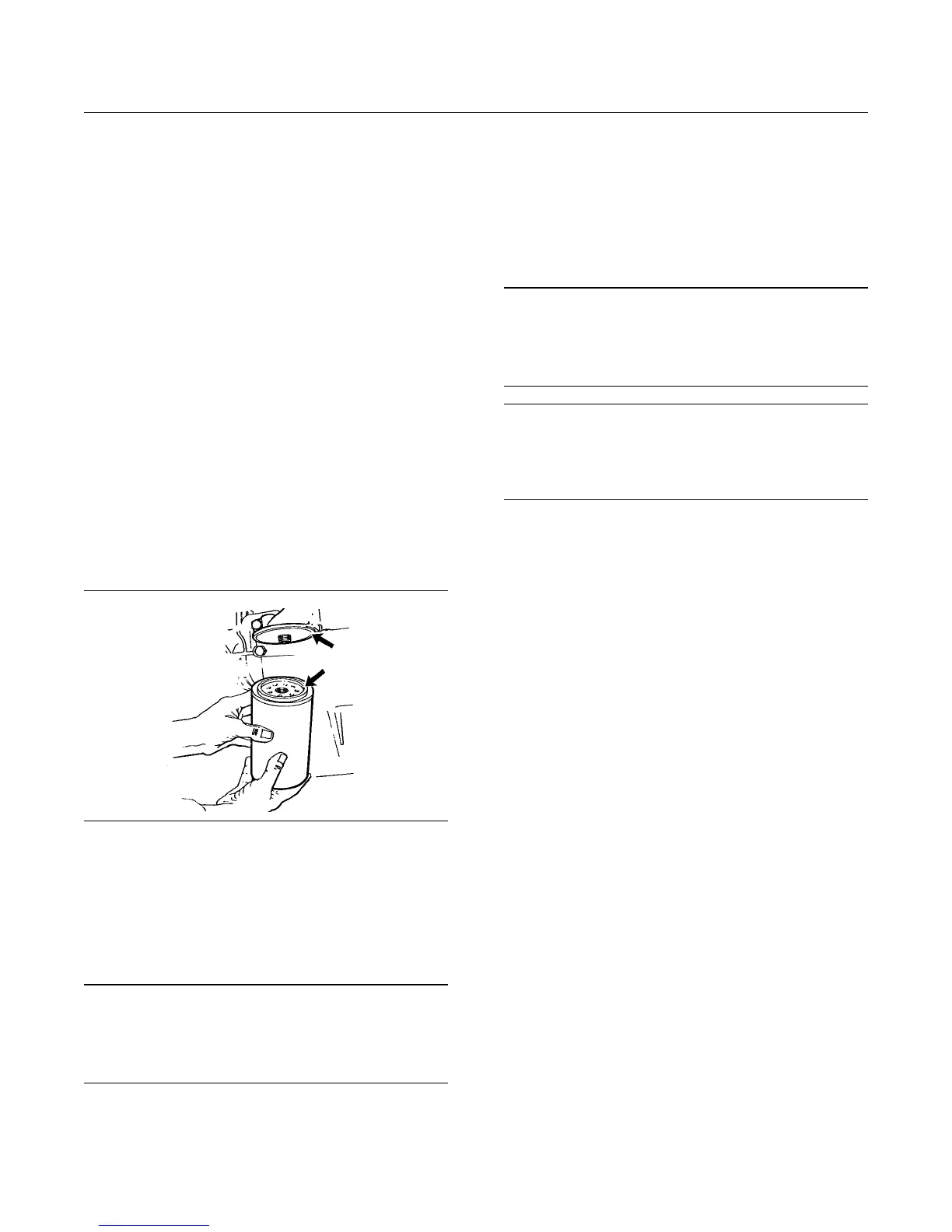

g00103713

Illustration 28

Typical filter mounting base and filter gasket

3. Clean the sealing surface of the filter mounting

base. Ensure that all of the old oil filter gasket

is removed.

4. Apply clean engine oil to the new oil filter gasket.

NOTICE

Do not fill the oil filters with oil before installing them.

This oil would not be filtered and could be contaminat-

ed. Contaminated oil can cause accelerated wear to

engine components.

5. Install the oil filter. Tighten the oil filter until the

oil filter gasket contacts the base. Tighten the oil

filter by hand according to the instructions that

are shown on the oil filter. Do not overtighten the

oil filter.

Fill the Engine Crankcase

1. Remove the oil filler cap. Refer to the Operation

and Maintenance Manual for more information on

lubricant specifications. Fill the crankcase with

the proper amount of oil. Refer to the Operation

and Maintenance Manual for more information

on refill capacities.

NOTICE

If equipped with an auxiliary oil filter system or a re-

mote oil filter system, follow the OEM or filter manu-

facturer’s recommendations. Under filling or overfilling

the crankcase with oil can cause engine damage.

NOTICE

To prevent crankshaft bearing damage, crank the en-

gine with the fuel OFF. This will fill the oil filters before

starting the engine. Do not crank the engine for more

than 30 seconds.

2. Start the engine and run the engine at “LOW

IDLE” for two minutes. Perform this procedure in

order to ensure that the lubrication system has

oil and that the oil filters are filled. Inspect the oil

filter for oil leaks.

3. Stop the engine and allow the oil to drain back

to the sump for a minimum of ten minutes.

4. Remove the oil level gauge in order to check the

oil level. Maintain the oil level between the “ADD”

and “FULL” marks on the oil level gauge.

i00626013

Engine Protective Devices -

Check

SMCS Code: 7400-535

Alarms and shutoffs must function properly. Alarms

provide timely warning to the operator. Shutoffs help

to prevent damage to the engine. It is impossible

to determine if the engine protective devices are

in good working order during normal operation.

Malfunctions must be simulated in order to test the

engine protective devices.

A calibration check of the engine protective devices

will ensure that the alarms and shutoffs activate

at the setpoints. Ensure that the engine protective

devices are functioning properly.

Loading...

Loading...