62

Maintenance Section

Aftercooler Core - Clean/Test

i01089688

Aftercooler Core - Clean/Test

SMCS Code: 1064-070; 1064-081

1. Remove the core. Refer to the Service Manual

for the procedure.

2. Turn the aftercooler core upside-down in order

to remove debris.

NOTICE

Do not use a high concentration of caustic cleaner to

clean the core. A high concentration of caustic cleaner

can attack the internal metals of the core and cause

leakage. Only use the recommended concentration of

cleaner.

3. Back flush the core with cleaner.

Caterpillar recommends the use of hot Hydrosolv

100 liquid cleaner at a concentration of 30% and

at a temperature of 66

to 82

C (150

to 180

F).

Table 35 lists the recommended Hydrosolv liquid

cleaners that are available from your Caterpillar

dealer.

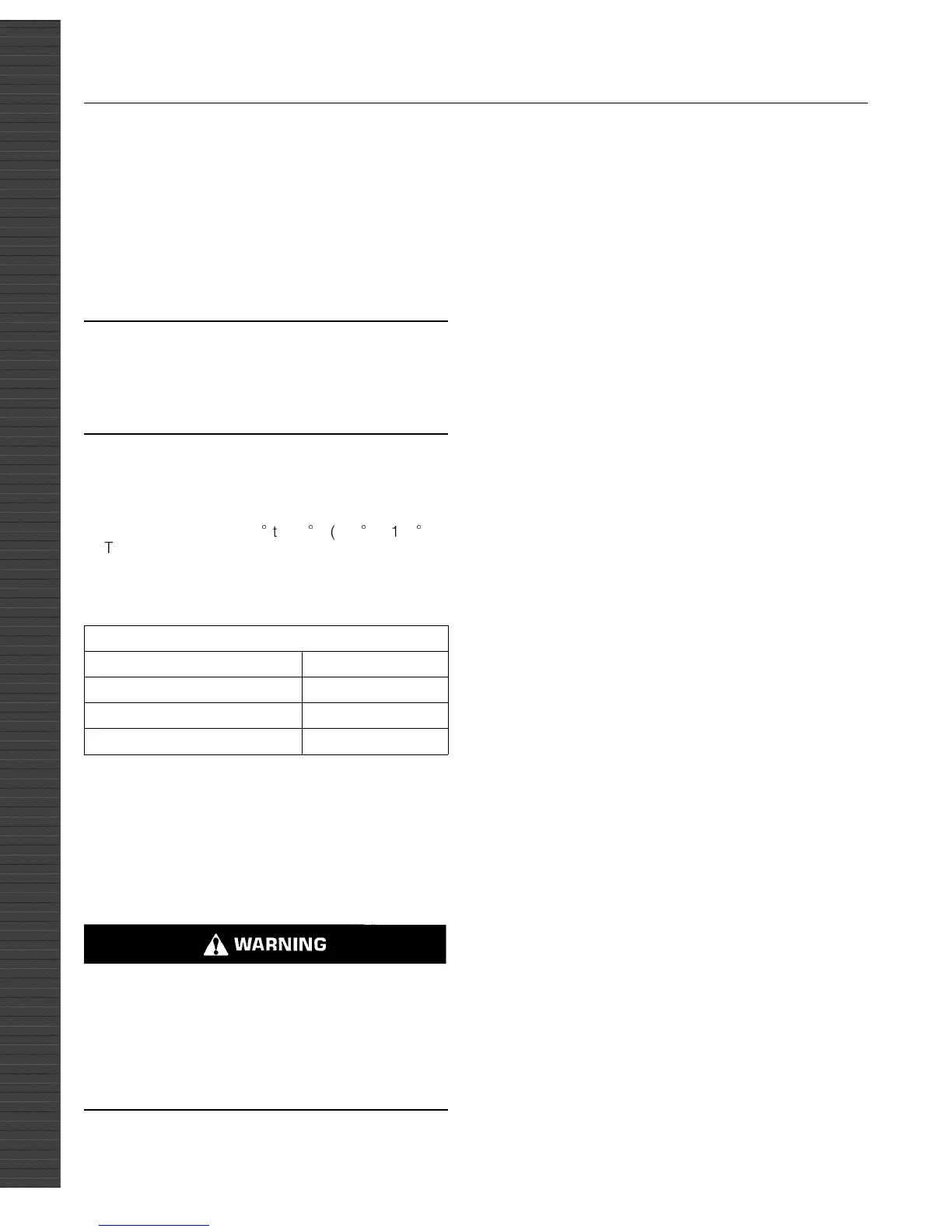

Ta bl e 3 5

Hydrosolv Liquid Cleaners

(1)

Description Container

1U-8804 Hydrosolv 100 4 L (1 US gal)

1U-5492 Hydrosolv 100 19 L (5 US gal)

8T-7571 Hydrosolv 100 208 L (55 US gal)

(1)

Refer to Application Guide, NEHS0526 or consult your

Caterpillar dealer for more information.

4. Steam clean the core in order to remove any

residue. Flush the fins of the aftercooler core.

Remove any other trapped debris.

5. Wash the core with hot, soapy water. Rinse the

core thoroughly with clean water.

Personal injury can result from air pressure.

Personal injury can result without following prop-

er procedure. When using pressure air, wear a pro-

tective face shield and protective clothing.

Maximum air pressure at the nozzle must be less

than 205 kPa (30 psi) for cleaning purposes.

6. Dry the core with compressed air. Direct the air

in the reverse direction of the normal flow.

7. Inspect the core in order to ensure cleanliness.

Pressure test the core. Many shops that service

radiators are equipped to perform pressure tests.

If necessary, repair the core.

8. Install the core. Refer to the Service Manual for

the procedure.

For more information on cleaning the core, consult

your Caterpillar dealer.

i01059376

Auxiliary Water Pump - Inspect

SMCS Code: 1371-040

Impellers require periodic inspection and seals

require periodic inspection. Impellers have a service

life that is limited. The service life depends on the

engine operating conditions.

Inspect the components of the pump more

frequently when the pump is exposed to debris,

sand, or other abrasive materials. Inspect the

components if the pump is operating at a differential

pressure of more than 103 kPa (15 psi).

Check the following components for wear and

check the following components for damage:

•

Cam

•

Impeller

•

Seals

•

Wear plate

If wear is found or if damage is found, replace

the components which are worn or replace the

components which are damaged. Use the proper

repair kit for the pump. Refer to the Disassembly

and Assembly for more information on servicing the

auxiliary water pump.

i00037658

Battery - Recycle

SMCS Code: 1401-561

1. Always recycle a battery. Never discard a battery.

2. Always return used batteries to one of the

following locations.

•

A battery supplier

•

An authorized battery collection facility

Loading...

Loading...