91

Maintenance Section

Zinc Rods - Inspect/Replace

Visually inspect the water pump for leaks. If any

leaking is observed, replace the water pump

seal or the water pump assembly. Refer to the

Service Manual for the disassembly and assembly

procedure.

Note: Refer to the Service Manual or consult your

Caterpillar dealer if any repair is needed or any

replacement is needed.

i01007424

Zinc Rods - Inspect/Replace

SMCS Code: 1388-040; 1388-510

Corrosion in sea water circuits can result in

premature deterioration of cooling system

components, leaks, and possible cooling system

contamination. The corrosion may be caused by the

lack of zinc rods in the sea water system.

Zinc rods are inserted in the sea water cooling

system of the engine in order to help prevent the

corrosive oxidation that is caused by sea water. The

reaction of the zinc to the sea water causes the

zinc rods to oxidize rather than the cooling system

components. Rapid deterioration of zinc rods may

indicate the presence of uncontrolled electrical

currents from improperly installed electrical

attachments or improperly grounded electrical

attachments.

The zinc rods must be inspected at the proper

intervals. The zinc rods must be replaced when

deterioration occurs.

Inspect the Zinc Rods

The zinc rods are red for easy identification. Table

38 shows the locations of the zinc rods and the

quantities of the zinc rod:

Ta bl e 3 8

Locations of the Zinc Rods

Location Quantity

Heat Exchanger 3

Transmission Oil Cooler

(1)

2

Exhaust Elbow

(2)

1

Aftercooler

(3)

5

(1)

Zinc rods will only be located in marine transmission oil coolers

that are cooled with sea water.

(2)

Exhaust elbows that are aftermarket may or may not be

equipped with zinc rods.

(3)

3126 Engine Only

1. Remove the zinc rod.

2. Inspect the zinc rod.

Ensure that the zinc rod will remain effective until

the next scheduled inspection.

a. If the zinc rod has deteriorated excessively,

install a new zinc rod.

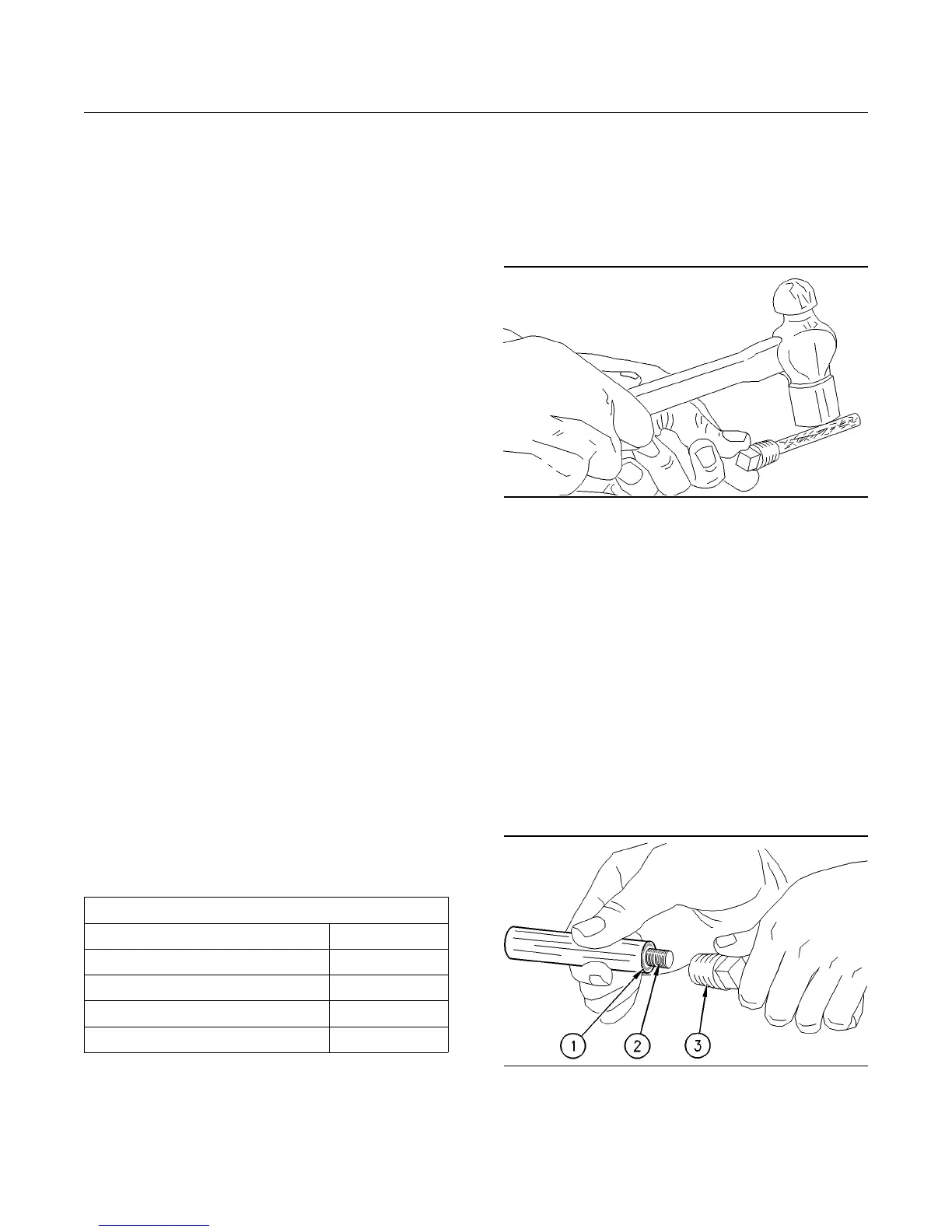

g00481100

Illustration 37

b. Tap the zinc rod lightly with a hammer. If the

zinc rod flakes, install a new zinc rod.

3. If the zinc rod will be reused, scrape the layer of

oxidation from the zinc rod before installation.

The layer of oxidation reduces the effectiveness

of the zinc rod.

Replace the Zinc Rods

1. Unscrew the old zinc rod from the plug.

If not enough material remains or the zinc rod has

broken off, drill the old zinc rod from the plug.

2. Clean the plug.

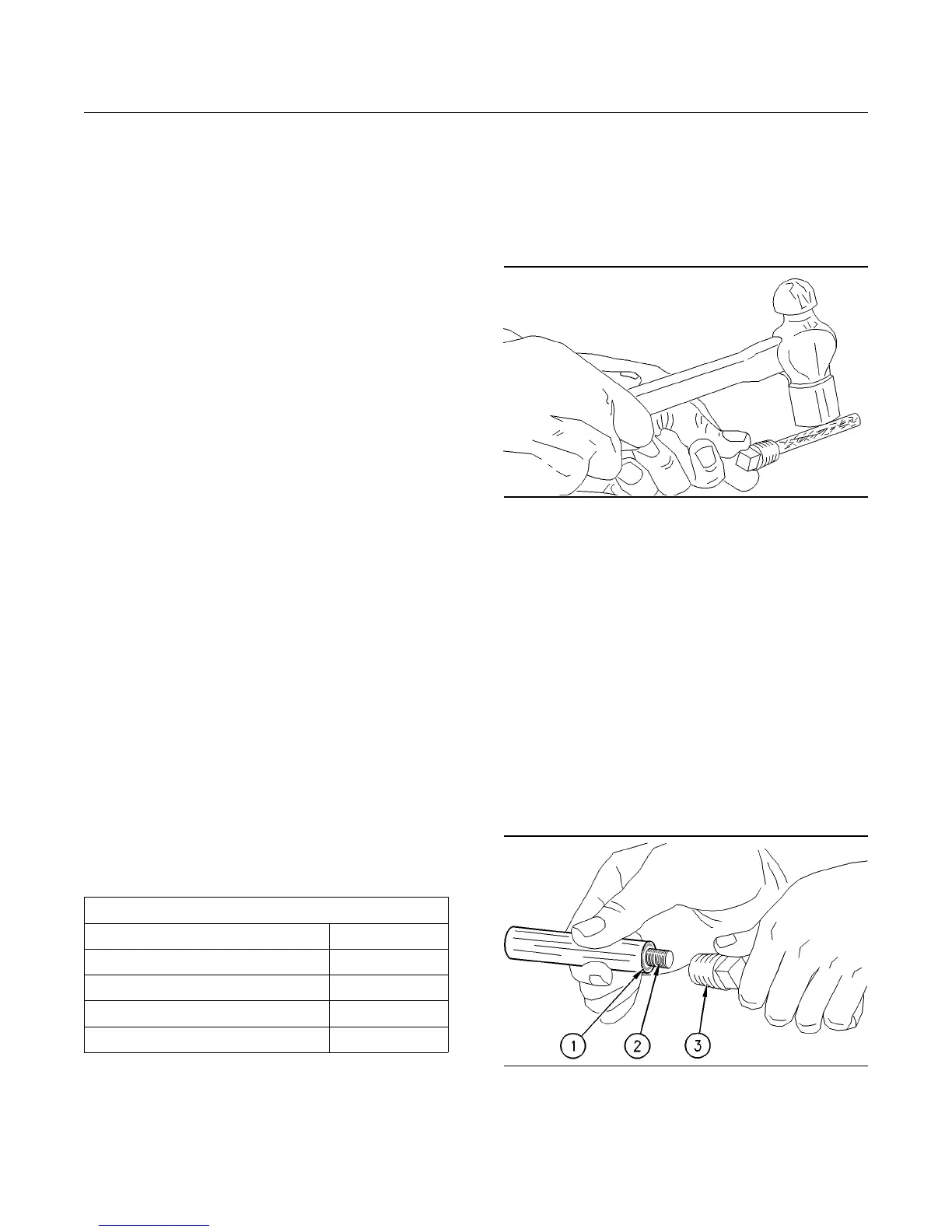

g00480345

Illustration 38

(1) Shoulder of the zinc rod

(2) Threads of the zinc rod

(3) External threads of the plug

Note: DO NOT apply adhesive or sealant to threads

(2) of the zinc rod.

Loading...

Loading...