68

Maintenance Section

Cooling System Coolant (ELC) - Change

NOTICE

Dispose of used engine coolant properly or recycle.

Various methods have been proposed to reclaim used

coolant for reuse in engine cooling systems. The full

distillation procedure is the only method acceptable by

Caterpillar to reclaim the used coolant.

For information regarding the disposal and the

recycling of used coolant, consult your Caterpillar

dealer or consult Caterpillar Service Technology

Group:

Outside Illinois: 1-800-542-TOOL

Inside Illinois: 1-800-541-TOOL

Canada: 1-800-523-TOOL

Flush

1. Flush the cooling system with clean water in

order to remove any debris.

2. Close the drain valve (if equipped). Clean the

drain plugs. Install the drain plugs. Refer to

the Specifications Manual for your particular

engine for more specific information on the

proper torques. Refer to the Specifications,

SENR3130, “Torque Specifications” for more

general information on the proper torques.

NOTICE

Fill the cooling system no faster than 19 L (5 US gal)

per minute to avoid air locks.

3. Fill the cooling system with clean water. Install

the cooling system filler cap.

4. Start the engine and run the engine at low

idle until the temperature reaches 49 to 66

C

(120 to 150

F).

5. Stop the engine and allow the engine to cool.

Loosen the cooling system filler cap slowly

in order to relieve any pressure. Remove the

cooling system filler cap. Open the drain valve (if

equipped) or remove the cooling system drain

plugs. Allow the water to drain. Flush the cooling

system with clean water. Close the drain valve (if

equipped). Clean the drain plugs. Install the drain

plugs. Refer to the Specifications Manual for your

particular engine for more specific information on

the proper torques. Refer to the Specifications,

SENR3130, “Torque Specifications” for more

general information on the proper torques.

Fill

Engines that are Equipped with a Coolant

Recovery Tank

NOTICE

Fill the cooling system no faster than 19 L (5 US gal)

per minute to avoid air locks.

1. Fill the cooling system with Extended Life Coolant

(ELC). Refer to the Operation and Maintenance

Manual, “Cooling System Specifications” topic

(Maintenance Section) for more information on

cooling system specifications. Do not install the

cooling system filler cap.

2. Place the transmission in neutral. Start the engine

and operate the engine at low idle. Increase the

engine rpm to 1500 rpm. Operate the engine at

1500 rpm for one minute in order to purge air

from the cavities of the engine block. Stop the

engine.

3. Pour more ELC into the cooling system until the

cooling system is full.

4. Clean the cooling system filler cap. Inspect the

gasket that is on the cooling system filler cap. If

the gasket that is on the cooling system filler cap

is damaged, discard the old cooling system filler

cap and install a new cooling system filler cap. If

the gasket that is on the cooling system filler cap

is not damaged, use a 9S-8140 Pressurizing

Pump in order to pressure test the cooling

system filler cap. The correct pressure for the

cooling system filler cap is stamped on the face

of the cooling system filler cap. If the cooling

system filler cap does not retain the correct

pressure, install a new cooling system filler cap.

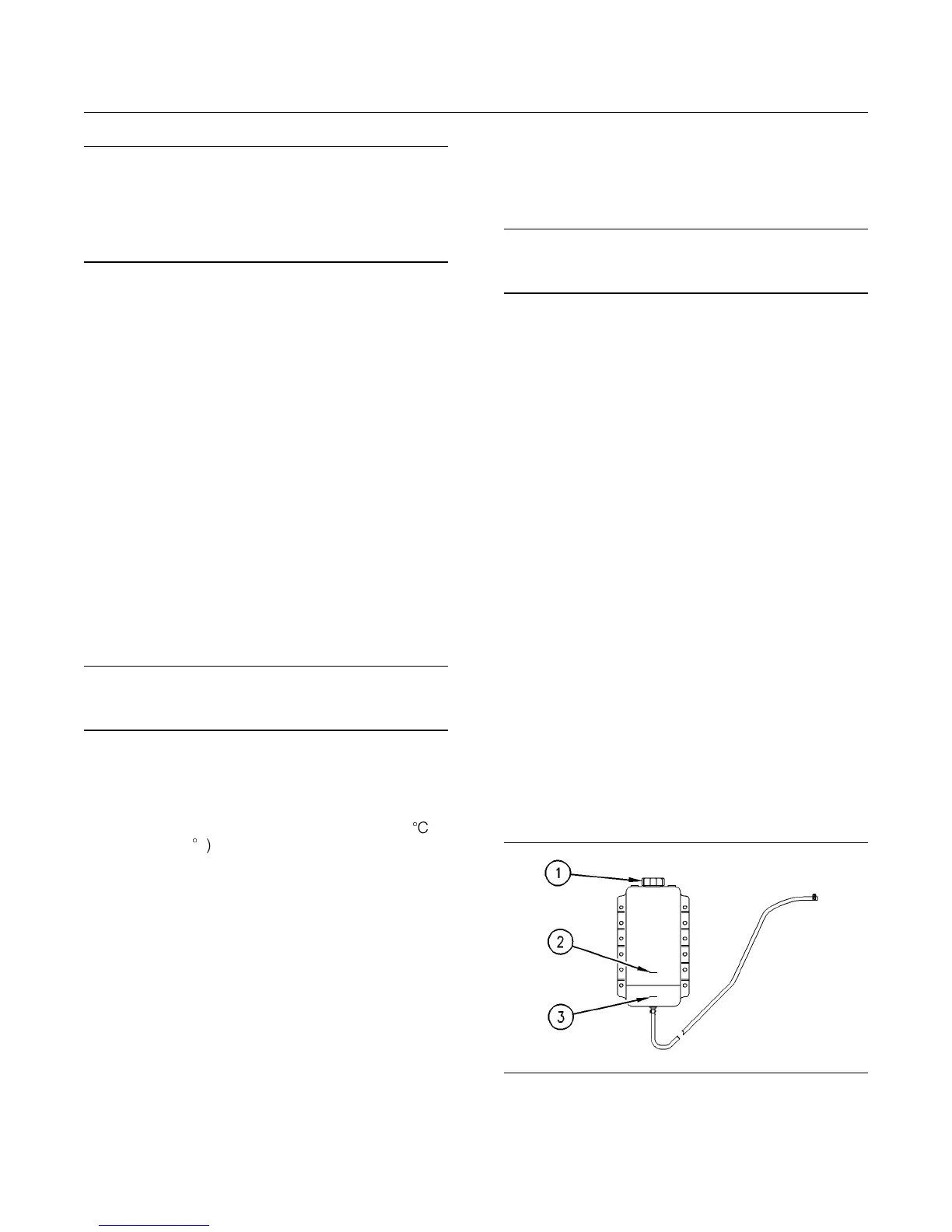

g00103638

Illustration 19

(1) Recovery tank filler cap

(2) “COLD FULL” mark

(3) “LOW ADD” mark

Loading...

Loading...