i01546702

Aftercooler Core - Clean/Test

SMCS Code: 1064-070; 1064-081

1. Remove the core. Refer to the Service Manual for

the procedure.

2. Turn the aftercooler core upside-down in order to

remove debris.

NOTICE

Do not use a high concentration of caustic cleaner to

clean the core. A high concentration of caustic

cleaner can attack the internal metals of the core and

cause leakage. Only use the recommended concen-

tration of cleaner.

3. Back flush the core with cleaner.

Caterpillar recommends the use of Hydrosolv

liquid cleaner. Table 18 lists Hydrosolv liquid

cleaners that are available from your Caterpillar

dealer.

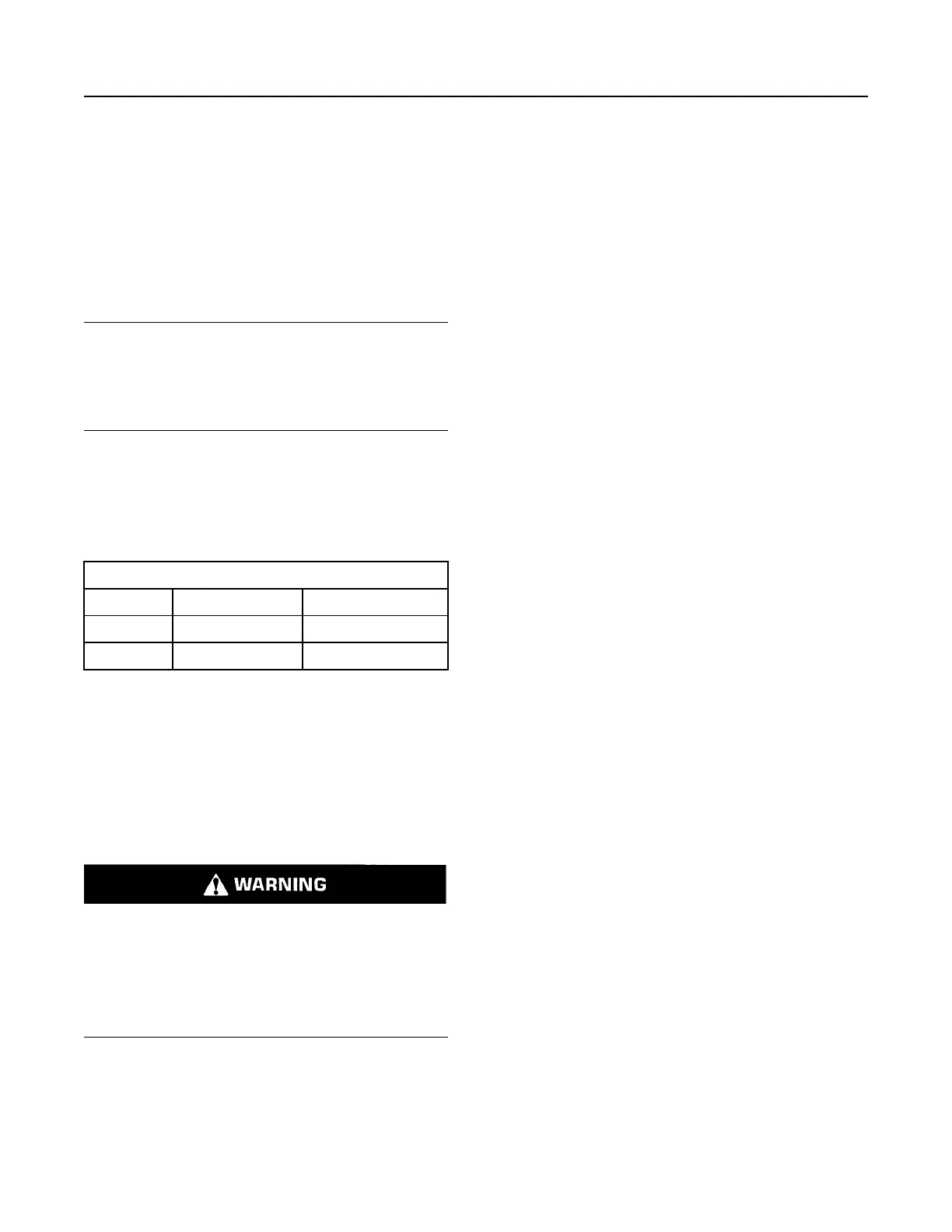

Table 18

Hydrosolv Liquid Cleaners

(1)

Part Number

Description

Size

1U-5490

Hydrosolv 4165 19 L (5 US gallon)

174-6854

Hydrosolv 100 19 L (5 US gallon)

(1)

Use a two to five percent concentration of the cleaner at tem-

peratures up to 93°C (200°F). Refer to Application Guide,

NEHS0526 or consult your Caterpillar dealer for more

information.

4. Steam clean the core in order to remove any

residue. Flush the fins of the aftercooler core.

Remove any other trapped debris.

5. Wash the core with hot, soapy water. Rinse the

core thoroughly with clean water.

Personal injury can result from air pressure.

Personal injury can result without following prop-

er procedure. When using pressure air, wear a

protective face shield and protective clothing.

Maximum air pressure at the nozzle must be less

than 205 kPa (30 psi) for cleaning purposes.

6. Dry the core with compressed air. Direct the air in

the reverse direction of the normal flow.

7. Inspect the core in order to ensure cleanliness.

Pressure test the core. Many shops that service

radiators are equipped to perform pressure tests.

If necessary, repair the core.

8. Install the core. Refer to the Service Manual for the

procedure.

For more information on cleaning the core, consult

your Caterpillar dealer.

i02676048

Alternator - Inspect

SMCS Code: 1405-040

Caterpillar recommends a scheduled inspection of

the alternator. Inspect the alternator for loose

connections and proper battery charging. Inspect the

ammeter (if equipped) during engine operation in

order to ensure proper battery performance and/or

proper performance of the electrical system. Make

repairs, as required.

Check the alternator and the battery charger for

proper operation. If the batteries are properly

charged, the ammeter reading should be very near

zero. All batteries should be kept charged. The

batteries should be kept warm because temperature

affects the cranking power. If the battery is too cold,

the battery will not crank the engine. The battery will

not crank the engine, even if the engine is warm.

When the engine is not run for long periods of time or

if the engine is run for short periods, the batteries

may not fully charge. A battery with a low charge will

freeze more easily than a battery with a full charge.

i00656523

Alternator and Fan Belts -

Inspect/Adjust/Replace

SMCS Code: 1357-039

Inspection

Belt tension should be checked initially between

the first 20 to 40 hours of engine operation.

After the initial check, the belt tension should be

checked at Every 250 Service Hours or Three

Months.

To maximize the engine performance, inspect the

belts for wear and for cracking. Replace belts that are

worn or damaged.

For applications that require multiple drive belts,

replace the belts in matched sets. Replacing only one

belt of a matched set will cause the new belt to carry

more load because the older belt is stretched. The

additional load on the new belt could cause the new

belt to break.

If the belts are too loose, vibration causes

unnecessary wear on the belts and pulleys. Loose

belts may slip enough to cause overheating.

106

SEBU7125-13

Maintenance Section

Aftercooler Core - Clean/Test

Loading...

Loading...