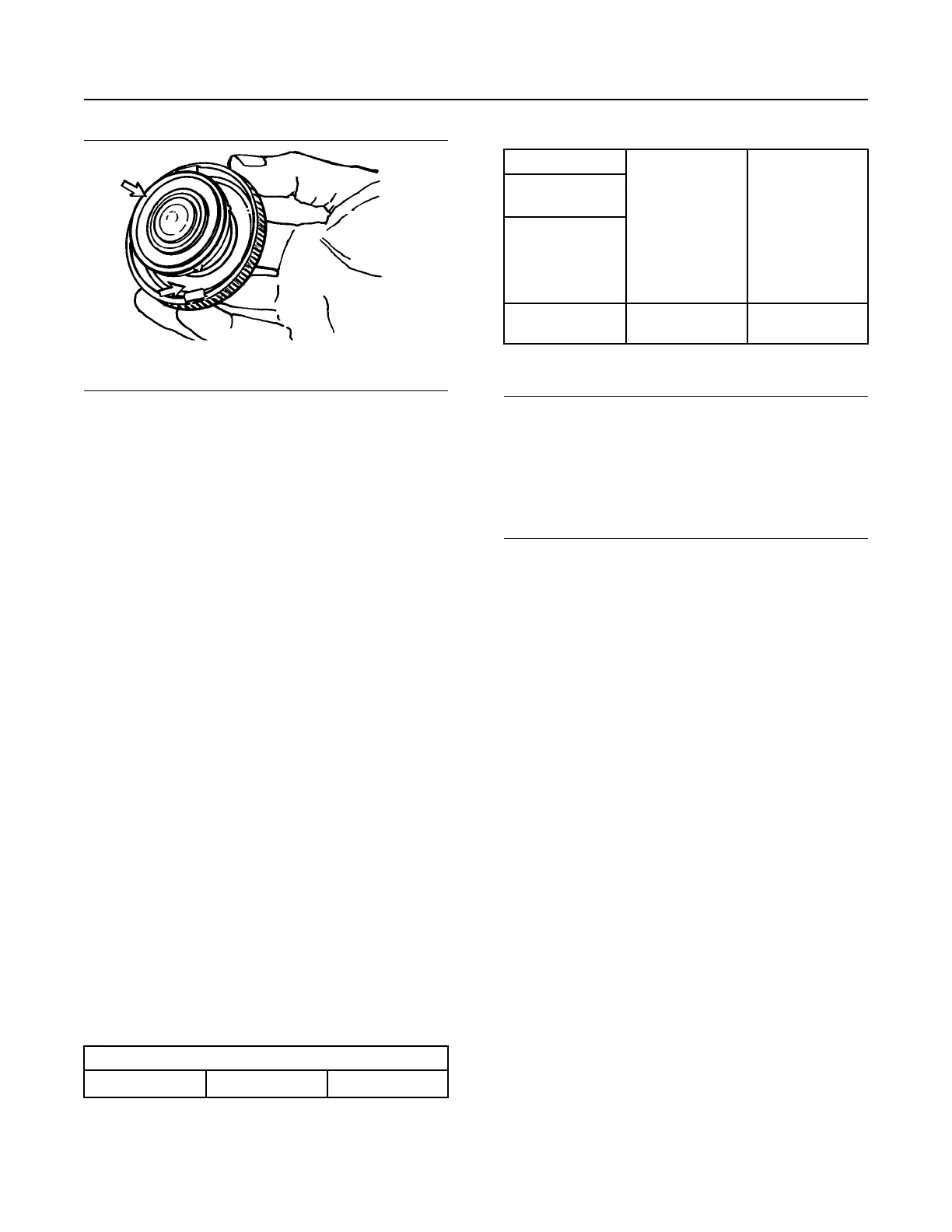

Illustration 97 g00103639

Typical filler cap gaskets

3. Clean the cooling system filler cap and check the

condition of the filler cap gaskets. Replace the

cooling system filler cap if the filler cap gaskets are

damaged. Reinstall the cooling system filler cap.

4. Inspect the cooling system for leaks.

i04035949

Cooling System Coolant

Sample (Level 1) - Obtain

SMCS Code: 1350-008; 1395-008; 1395-554; 7542

Note: Obtaining a Coolant Sample (Level 1) is

optional if the cooling system is filled with Cat

ELC (Extended Life Coolant). Cooling systems

filled with Cat ELC should have a Coolant Sample

(Level 2) that is obtained at the recommended

interval as stated in the maintenance interval

schedule.

Note: Obtain a Coolant Sample (Level 1) if the

cooling system is filled with any other coolant

instead of Cat ELC including the following

coolants:

• Commercial long life coolants that meet the

Caterpillar Engine Coolant Specification -1

(Caterpillar EC-1)

• Cat DEAC (Diesel Engine Antifreeze/Coolant)

• Commercial heavy-duty coolant/antifreeze

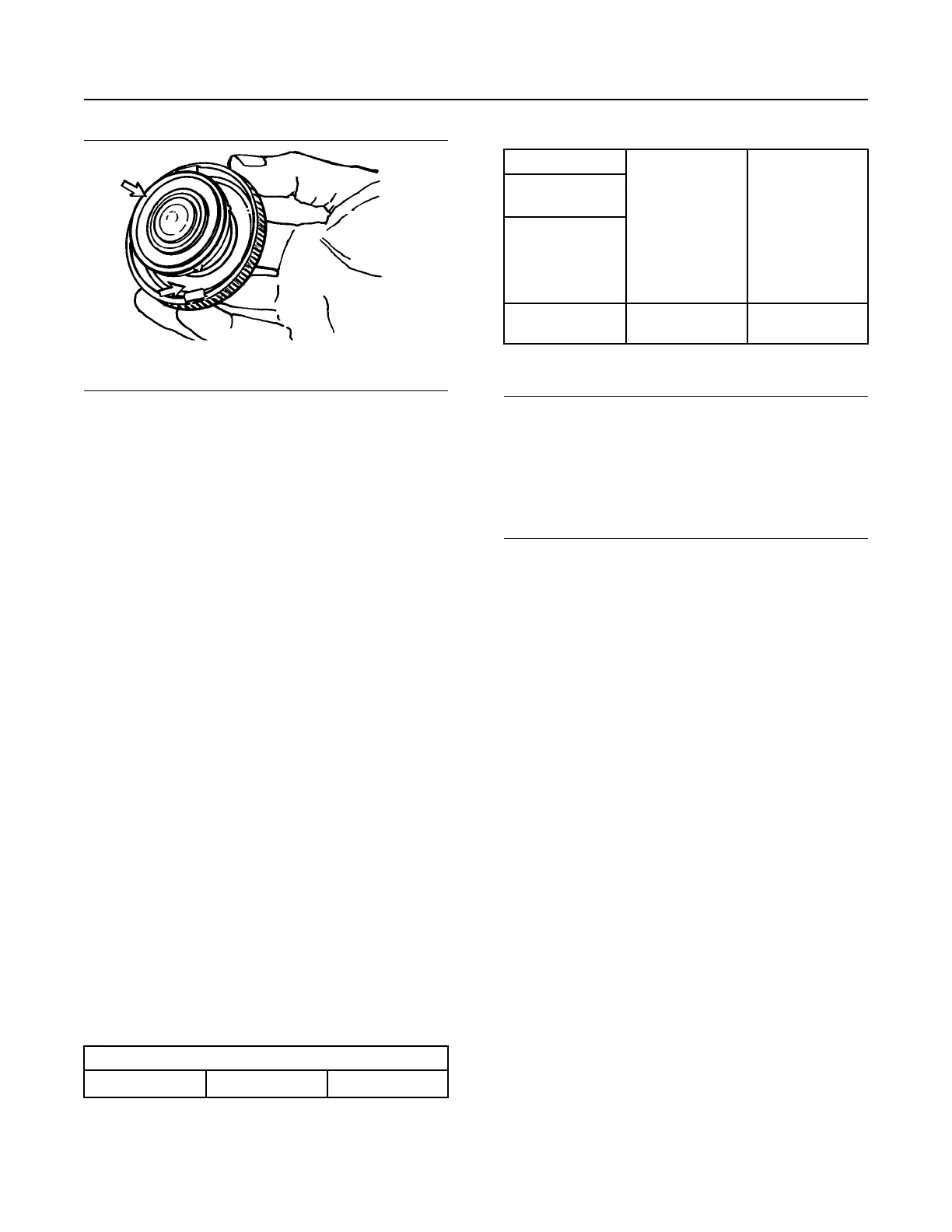

Table 19

Recommended Interval

Type of Coolant

Level 1 Level 2

(continued)

(Table 19, contd)

Cat DEAC

Every 250 service

hours

Every year

(1)

Conventional heavy

duty-coolant

Commercial coolant

that meets the re-

quirements of the

Caterpillar EC-1

standard

Cat ELC or conven-

tional EC-1 coolant

Optional Every year

(1)

(1)

The Level 2 Coolant Analysis should be performed sooner if a

problem is suspected or identified.

NOTICE

Always use a designated pump for oil sampling, and

use a separate designated pump for coolant sam-

pling. Using the same pump for both types of sam-

ples may contaminate the samples that are being

drawn. This contaminate may cause a false analysis

and an incorrect interpretation that could lead to con-

cerns by both dealers and customers.

Note: Level 1 results may indicate a need for

Level 2 Analysis.

Obtain the sample of the coolant as close as possible

to the recommended sampling interval. In order to

receive the full effect of S·O·S analysis, establish a

consistent trend of data. In order to establish a

pertinent history of data, perform consistent

samplings that are evenly spaced. Supplies for

collecting samples can be obtained from your

Caterpillar dealer.

Use the following guidelines for proper sampling of

the coolant:

• Complete the information on the label for the

sampling bottle before you begin to take the

samples.

• Keep the unused sampling bottles stored in plastic

bags.

• Obtain coolant samples directly from the coolant

sample port. You should not obtain the samples

from any other location.

• Keep the lids on empty sampling bottles until you

are ready to collect the sample.

• Place the sample in the mailing tube immediately

after obtaining the sample in order to avoid

contamination.

• Never collect samples from expansion bottles.

• Never collect samples from the drain for a system.

Submit the sample for Level 1 analysis.

SEBU7125-13

113

Maintenance Section

Cooling System Coolant Sample (Level 1) - Obtain

Loading...

Loading...