i02139969

Engine Mounts - Inspect

SMCS Code: 1152-040

Inspect the engine mounts for deterioration and for

proper bolt torque. Engine vibration can be caused

by the following conditions:

• Improper mounting of the engine

• Deterioration of the engine mounts

Any engine mount that shows deterioration should be

replaced. Refer to the Specifications Manual,

SENR3130, “Torque Specifications”. Refer to your

Caterpillar dealer for more information.

i00623423

Engine Oil Level - Check

SMCS Code: 1348-535-FLV

Hot oil and hot components can cause personal

injury. Do not allow hot oil or hot components to

contact the skin.

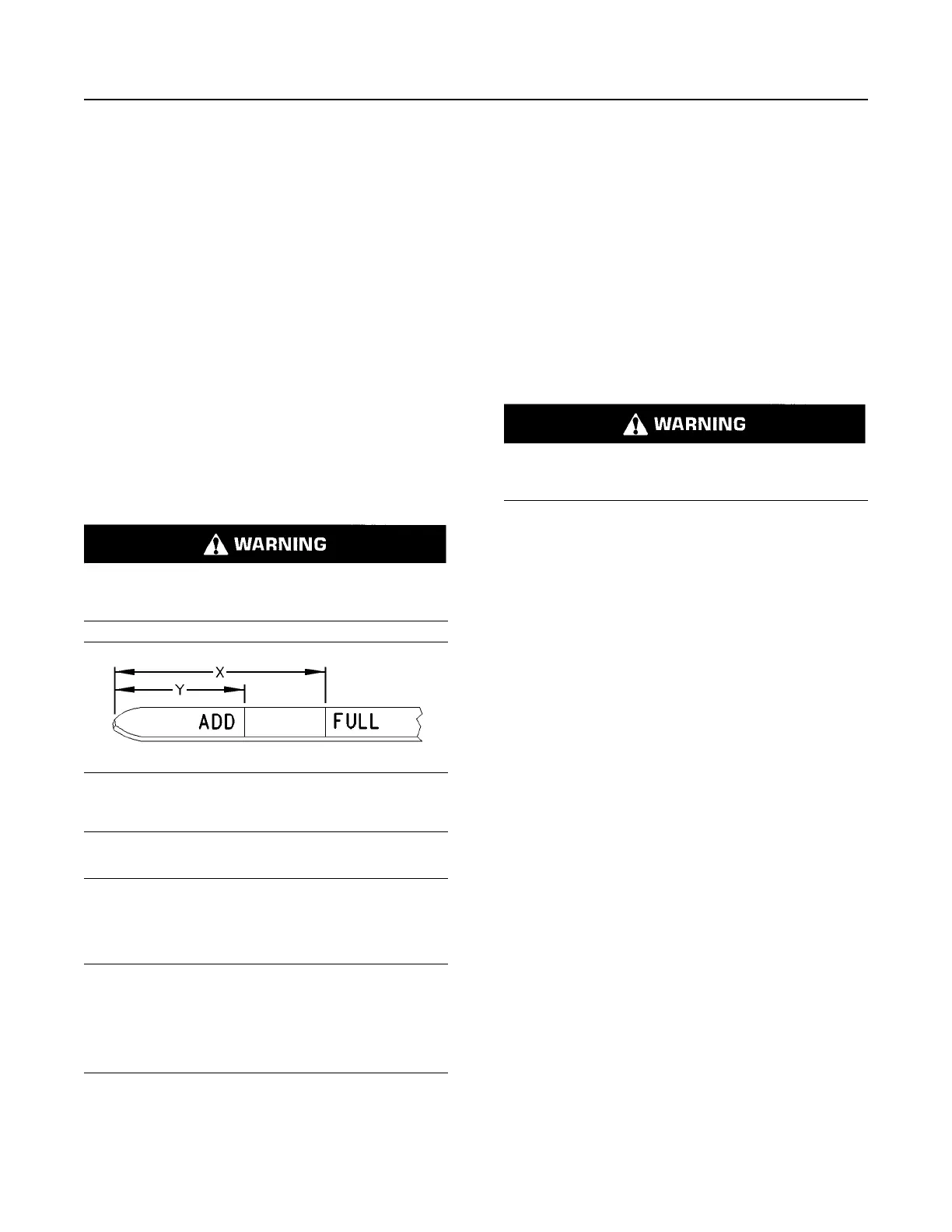

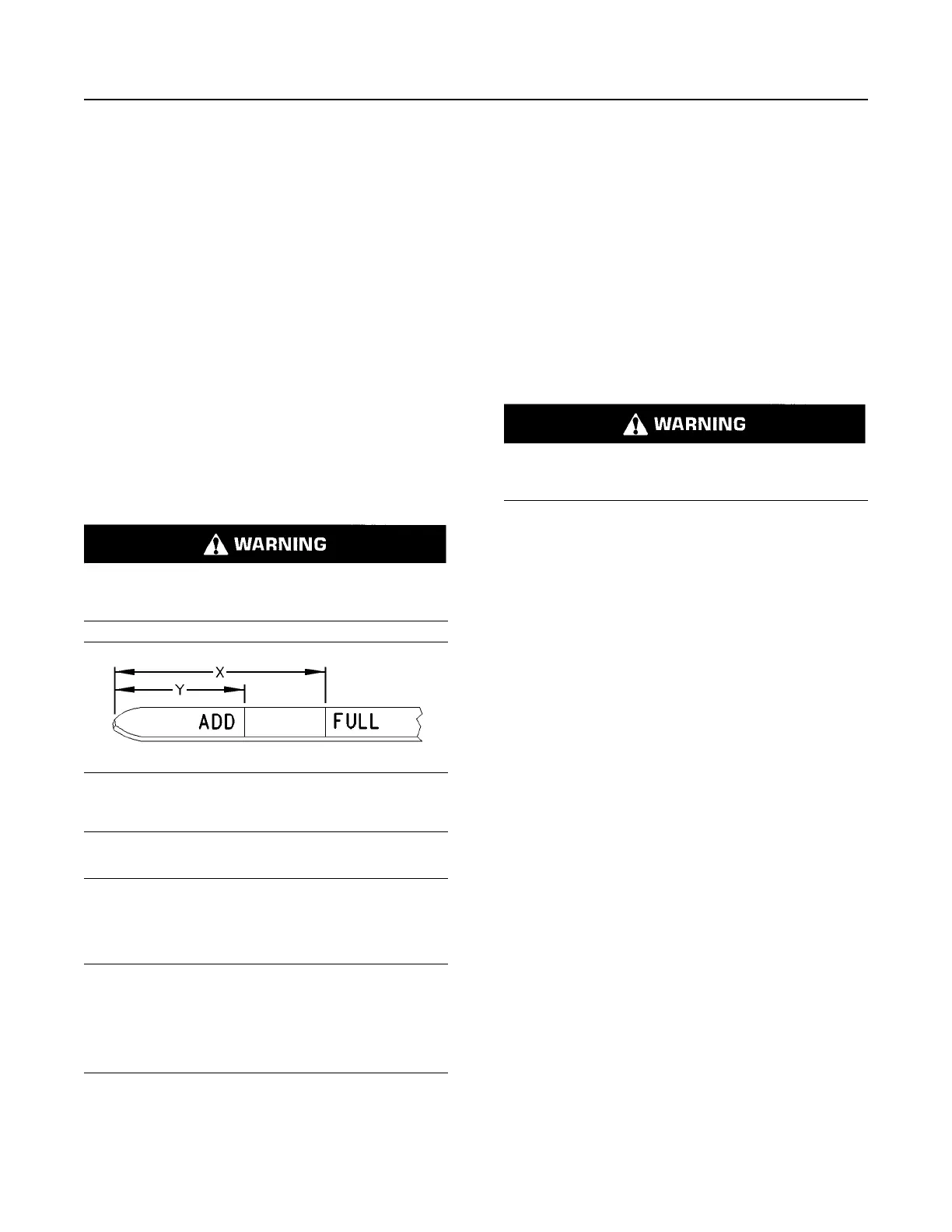

Illustration 105 g00110310

(Y) “ADD” mark. (X) “FULL” mark.

NOTICE

Perform this maintenance with the engine stopped.

1. Maintain the oil level between “ADD” mark (Y) and

“FULL” mark (X) on oil level gauge (1). Do not fill

the crankcase above “FULL” mark (X).

NOTICE

Operating your engine when the oil level is above the

“FULL” mark could cause your crankshaft to dip into

the oil. The air bubbles created from the crankshaft

dipping into the oil reduces the oil's lubricating char-

acteristics and could result in the loss of power.

2. Remove the oil filler cap and add oil, if necessary.

Clean the oil filler cap. Install the oil filler cap.

i04237495

Engine Oil Sample - Obtain

SMCS Code: 1000-008; 1348-554-SM; 7542-554-

SM; 7542-554-OC

In addition to a good preventive maintenance

program, Caterpillar recommends using S·O·S oil

analysis at regularly scheduled intervals. S·O·S oil

analysis provides infrared analysis, which is required

for determining nitration and oxidation levels.

Obtain the Sample and the

Analysis

Hot oil and hot components can cause personal

injury. Do not allow hot oil or hot components to

contact the skin.

Before you take the oil sample, complete the Label,

PEEP5031 for identification of the sample. In order to

help obtain the most accurate analysis, provide the

following information:

• Engine model

• Service hours on the engine

• The number of hours that have accumulated since

the last oil change

• The amount of oil that has been added since the

last oil change

To ensure that the sample is representative of the oil

in the crankcase, obtain a warm, mixed oil sample.

To avoid contamination of the oil samples, the tools

and the supplies that are used for obtaining oil

samples must be clean.

Caterpillar recommends using the sampling valve in

order to obtain oil samples. The quality and the

consistency of the samples are better when the

sampling valve is used. The location of the sampling

valve allows oil that is flowing under pressure to be

obtained during normal engine operation.

The 169-8373 Fluid Sampling Bottle is

recommended for use with the sampling valve. The

fluid sampling bottle includes the parts that are

needed for obtaining oil samples. Instructions are

also provided.

122

SEBU7125-13

Maintenance Section

Engine Mounts - Inspect

Loading...

Loading...