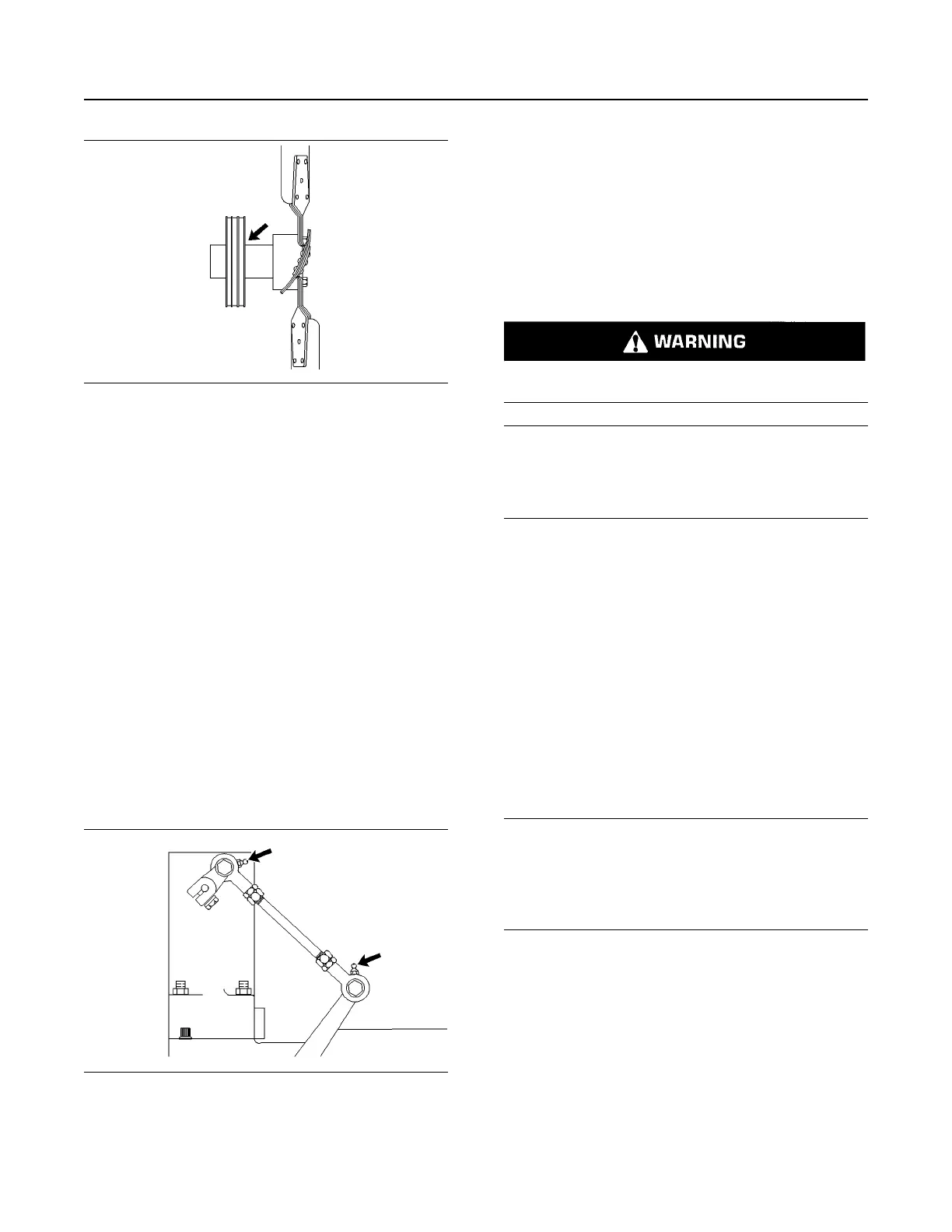

Illustration 107 g00746166

Typical location of the grease fitting (if equipped) that

is for the fan drive bearing

The pulley is shown with the belt guards that have

been removed.

Lubricate the grease fitting that is on the fan drive

bearing with High Speed Ball Bearing Grease or the

equivalent.

Inspect the fan drive pulley assembly for wear or for

damage. If the shaft is loose, an inspection of the

internal components should be performed. Refer to

the Systems Operation Testing and Adjusting Manual

for additional information.

i00705823

Fuel Control Linkage - Check/

Lubricate

SMCS Code: 1257-535; 1257-086

Check the fuel control linkage for proper operation. If

necessary, adjust the fuel control linkage . Refer to

the Service Manual for the adjustment procedures.

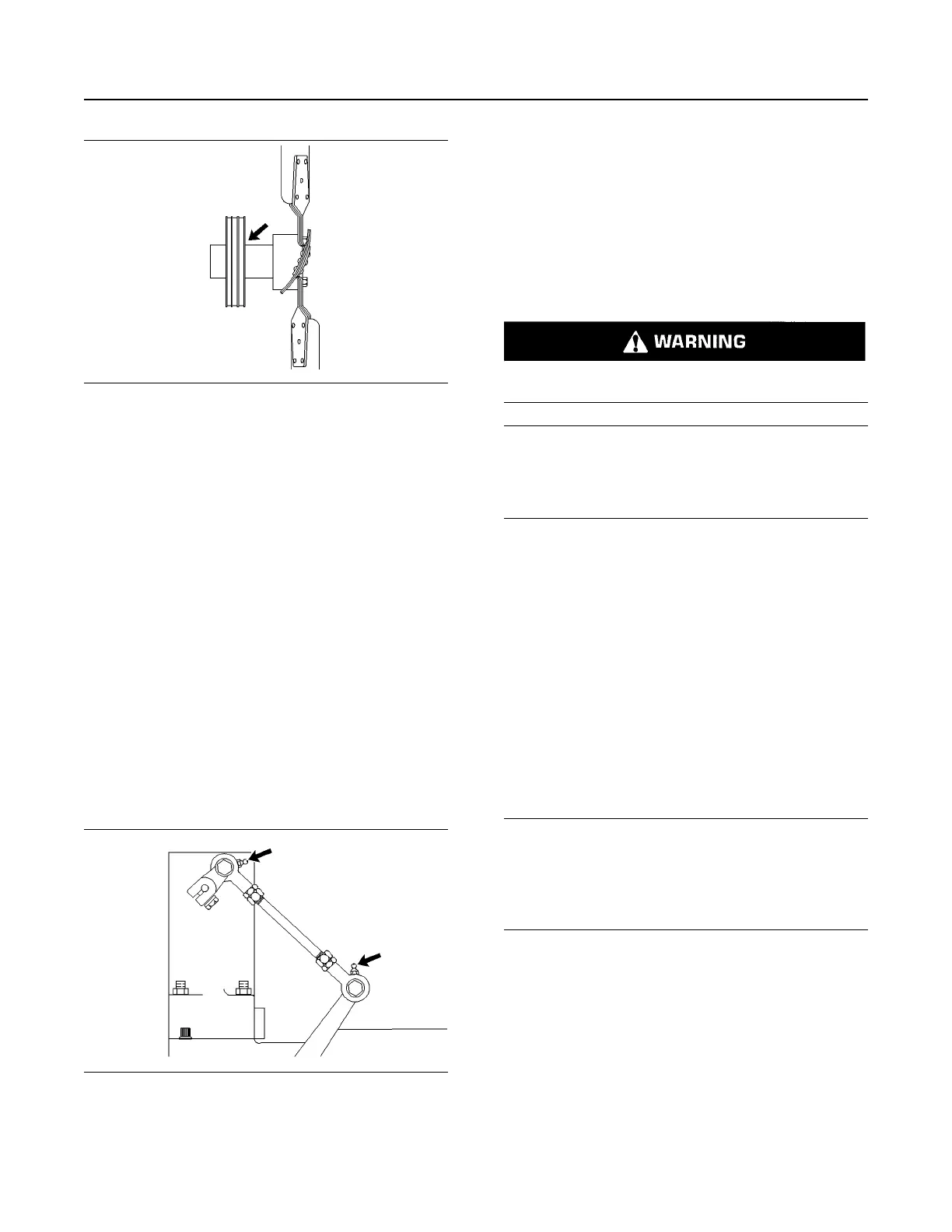

Illustration 108 g00309003

Typical grease fittings on the fuel control linkage

Some fuel control linkages require lubrication.

Lubricate the grease fittings with 1P-0808

Multipurpose Grease or the equivalent.

i00626014

Fuel Injection Nozzles - Test/

Exchange

SMCS Code: 1254-081; 1254-013

Fuel leaked or spilled onto hot surfaces or electri-

cal components can cause a fire.

NOTICE

Do not allow dirt to enter the fuel system. Thoroughly

clean the area around a fuel system component that

will be disconnected. Fit a suitable cover over discon-

nected fuel system component.

Fuel injection nozzles are subject to tip wear. Tip

wear is a result of fuel contamination. Tip wear can

cause the following problems:

• Increased fuel consumption

• Black smoke

• Misfire

• Rough running

Fuel Injection nozzles should be cleaned, inspected,

tested, and replaced, if necessary. Refer to Special

Instruction, SEHS7292 for using the 8S-2245

Injection Cleaning Tool Group. Consult your

Caterpillar dealer about cleaning the fuel injection

nozzle and testing the fuel injection nozzle.

NOTICE

Never wire brush or scrape a fuel injection nozzle.

Wire brushing or scraping a fuel injection nozzle will

damage the finely machine orifice. Proper tools for

cleaning and testing the fuel injection nozzles can be

obtained from Caterpillar dealers.

The following items are symptoms of a malfunction of

the fuel injection nozzle:

• Abnormal engine operation

• Smoke emission

• Engine knock

Each fuel injection nozzle must be isolated one at a

time in order to determine the malfunctioning fuel

injection nozzle.

1. Start the engine.

126

SEBU7125-13

Maintenance Section

Fuel Control Linkage - Check/Lubricate

Loading...

Loading...