After the initial cleaning with a vacuum, compressed

air may be used to remove the remaining dust and

dirt. Compressed air that is used for cleaning should

be free of moisture and free of oil. Air pressure

should be a maximum of 210 kPa (30 psi) in order to

prevent mechanical damage to the insulation. If the

above cleaning procedures are not effective, consult

a Cat dealer.

Cleaning (Disassembled

Generators)

An initial insulation resistance check should be made

on the generator in order to confirm electrical

integrity. A minimum reading of 1 megohm would be

expected with severely contaminated generators. A

zero megohm reading may indicate an insulation

breakdown. An insulation breakdown requires more

than cleaning. An insulation breakdown requires

repair.

A high-pressure wash is normally an effective way to

clean windings. Windings that have been exposed to

flooding, or windings that have been contaminated by

salt can be high-pressure washed as well. A solution

of hot water and detergent is used for this method of

cleaning.

A high-pressure wash sprays a high velocity fluid

stream of this solution over the generator that is

being cleaned. This detergent washing is followed by

multiple sprays of clean water. The clean water is

used in order to remove the detergent or the clean

water is used in order to dilute the detergent.

Allow the generator to dry at room temperature.

Check the insulation resistance. The insulation

resistance should now be normal. If the insulation

resistance is not normal, repeat the procedure. Use

of solvents may be necessary if the generator is

contaminated with oil or if the generator is

contaminated with grease.

Note: For more information on drying methods, refer

to Special Instructions, SEHS9124, “Cleaning and

Drying of Electric Set Generators”.

i03569354

Generator Bearing

Temperature - Measure/Record

SMCS Code: 4471-082-TA

Bearing temperature detectors are optional on

generators. Bearing temperature detectors are used

with equipment that has been provided by the

customer in order to measure the bearing

temperature. Bearing temperature detectors may

help to prevent premature bearing failure.

A bearing temperature that is 50 °C (122 °F) above

the ambient temperature may require a change in

operation. The unit should be shut down in order to

prevent damage if the bearing temperature is 50 °C

(122 °F) above the ambient temperature.

i04066149

Generator Lead (Flat Braided

Cable) - Check

(If Equipped)

SMCS Code: 4450-535

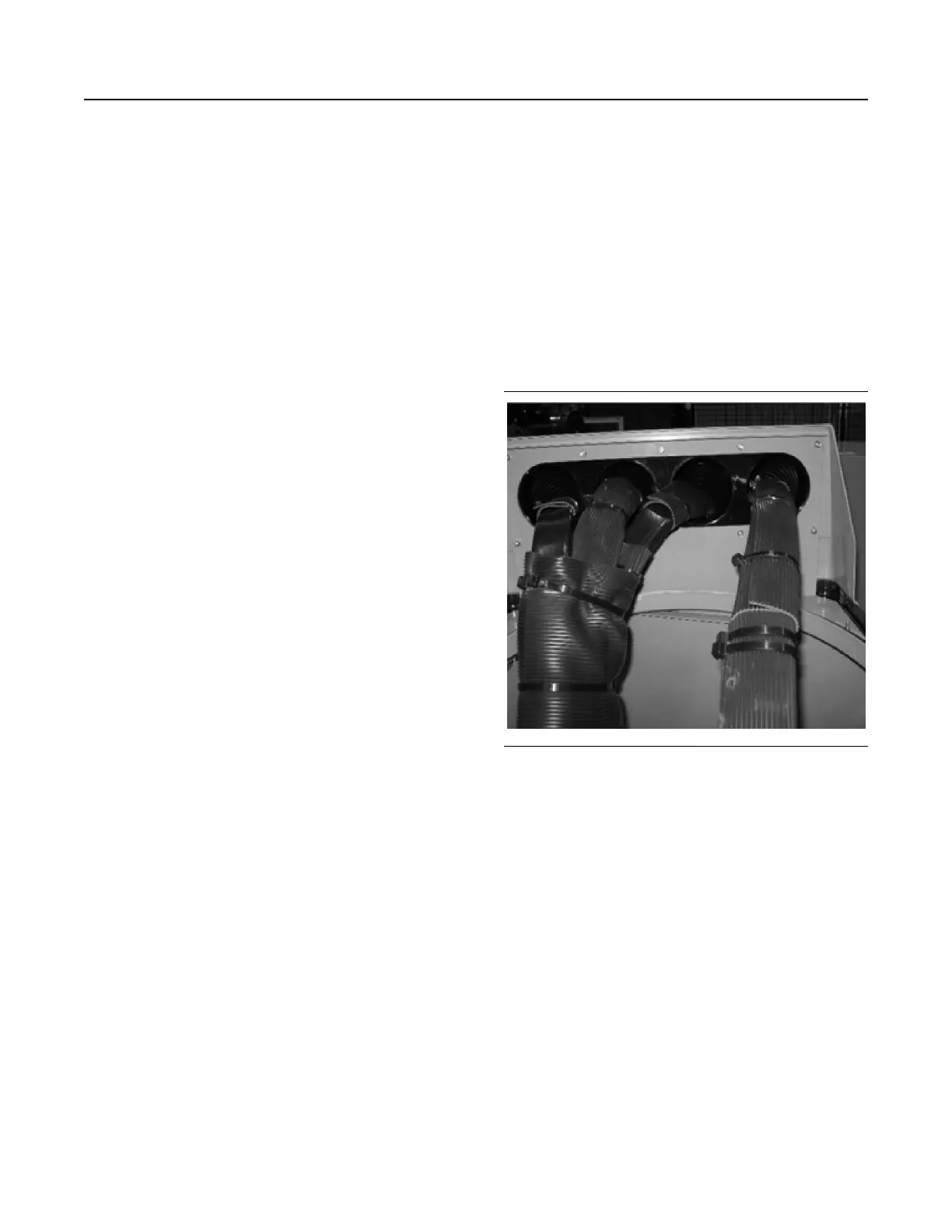

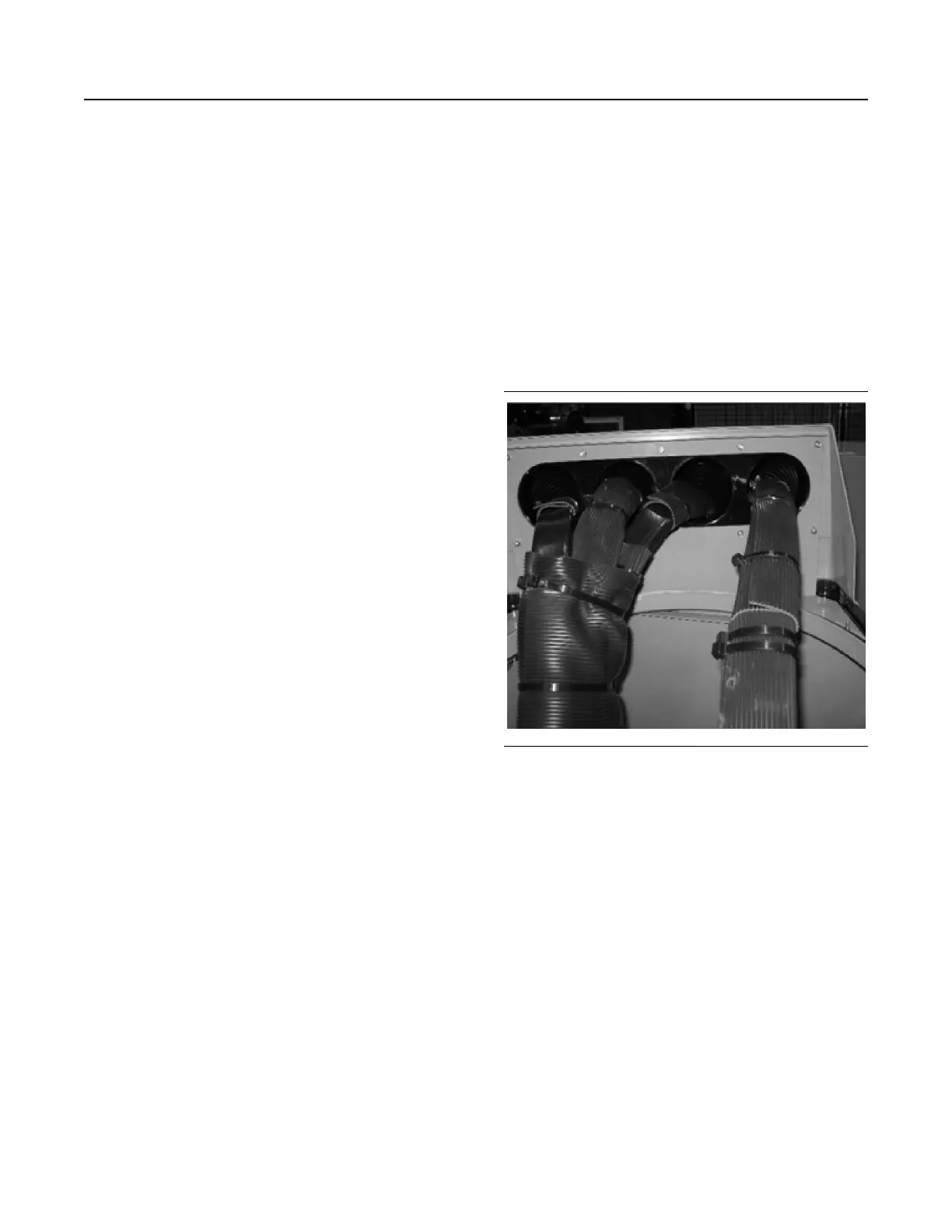

Illustration 115 g02146533

Typical flat braided conductor

The generator set may have braided square

conductors or multiple round cables between the

generator and the breaker.

Check braided conductors for signs of wear. Pay

particular attention to the conductor protective sleeve

insulation at the housing for the breaker and in the

generator terminal box. Replace the mat immediately

if the mat shows signs of wear at a point of contact.

Replace the cable immediately if the insulation shows

signs of wear at points of contact. If your generator

set does not have rubber mats in place, contact your

Cat dealer.

SEBU7125-13

135

Maintenance Section

Generator Bearing Temperature - Measure/Record

Loading...

Loading...