Generator Set Control (GSC)

Functions and Features of the GSC

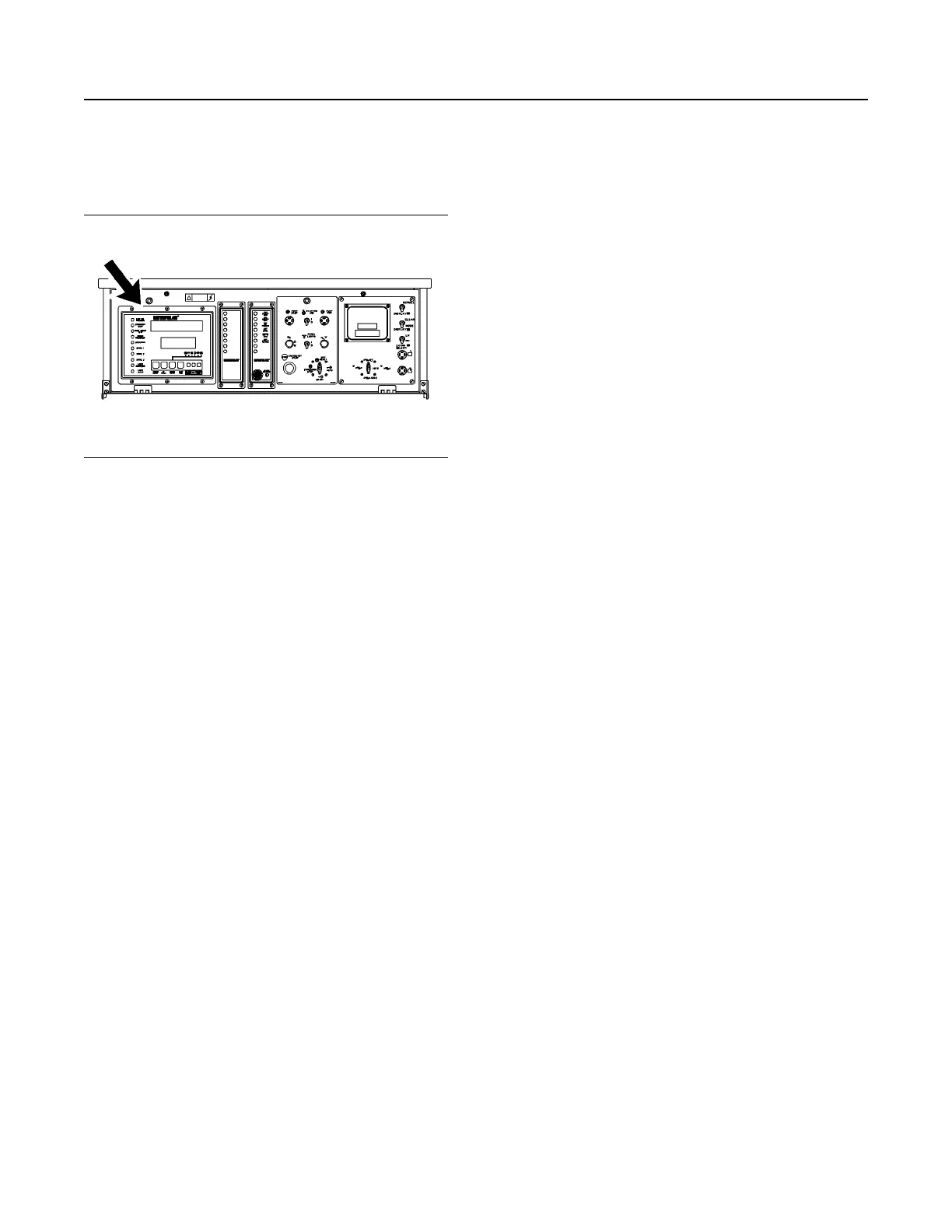

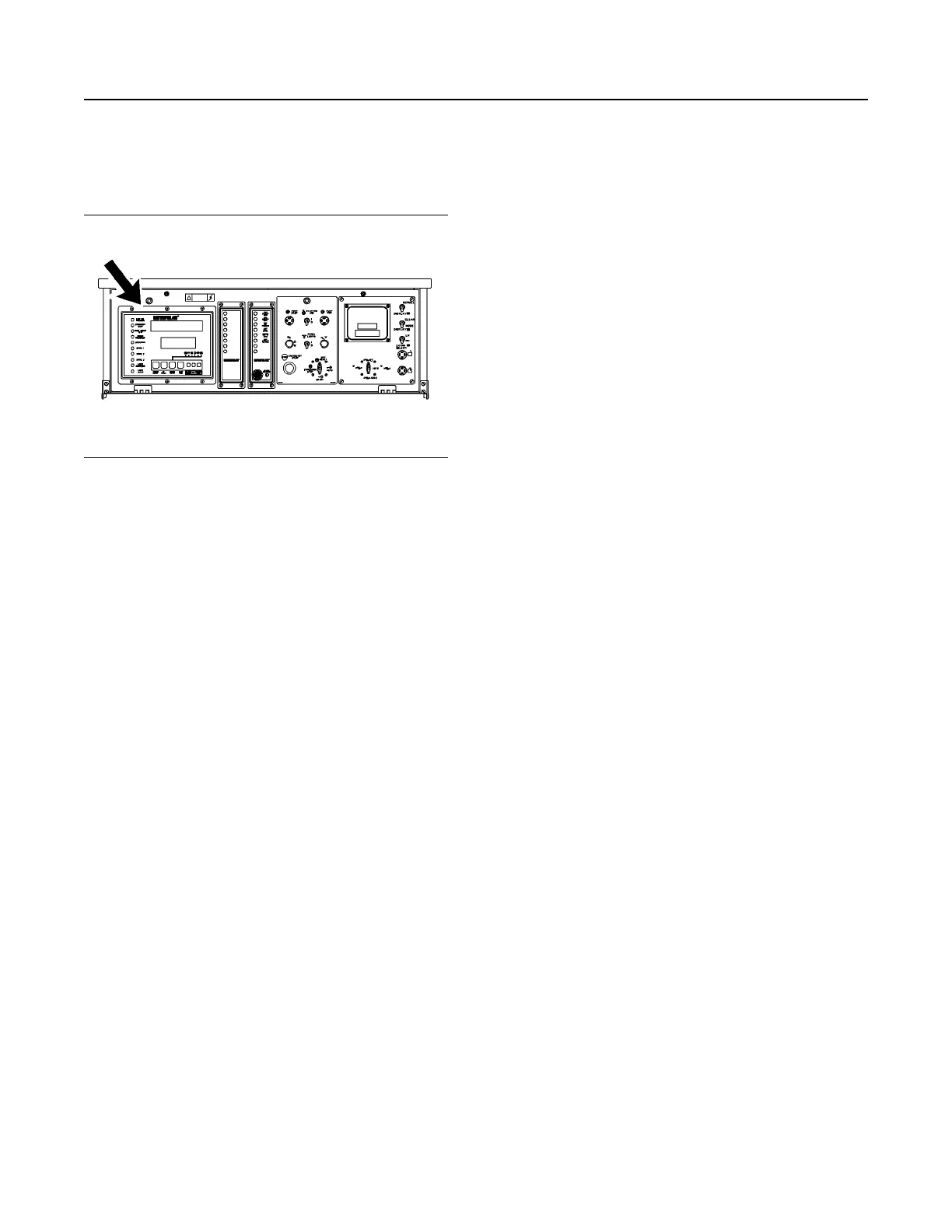

Illustration 49 g00643608

The Location of the GSC on the EMCP II Control

Panel

The left side of the control panel contains the

generator set control (GSC). The GSC is the main

component of the system. The GSC displays

generator output, generator set functions, fault

conditions and key engine parameters. The GSC

accepts information from the following sources:

operator, magnetic pickup, oil pressure sensor, water

temperature sensor and optional remote sources.

This information is used to determine the “ON/OFF”

state of the engine's air, fuel, and starter.

In the very basic operating conditions, the GSC

receives a signal in order to run the generator set.

The GSC turns on the engine's fuel and the engine

starter. When the engine speed reaches the crank

termination speed, the starter is disengaged. When

the GSC receives a signal to stop the engine, the

GSC shuts the fuel off.

The functions of the GSC are listed below.

• The GSC controls the normal starting and

stopping of the engine.

• The GSC shows engine conditions and generator

output information on two displays. The displays

also show fault codes and GSC programming

information.

• The GSC monitors the system for faults. If a fault

occurs, the GSC performs a controlled fault

shutdown or the GSC provides a fault alarm

annunciation. The GSC uses indicators and

displays in order to describe the fault.

• The GSC contains programmable features for

certain applications or customer requirements.

The features of the GSC are listed below.

• Cycle Crank : The GSC can be programmed to

crank for adjustable time periods. For

programming instructions, refer to the Systems

Operation, Testing and Adjusting, SENR5809,

“Electronic Modular Control Panel II (EMCP II) For

MUI Engines” or to the Systems Operation,

Testing and Adjusting, SENR5398, “Electronic

Modular Control Panel II (EMCP II) For EUI

Engines”.

• Governor Control : When the engine oil

pressure increases past the low oil pressure set

point, the GSC indicates that the governor should

increase the engine speed from idle rpm to rated

rpm.

• Cooldown : In order to perform a normal

shutdown upon receiving a signal, the GSC waits

for a preprogrammed time period before shutting

down the engine via the fuel control.

• Automatic Operation : In the automatic mode,

the GSC can be started by a remote signal

(contact closure). Upon loss of the signal (contact

opening), the GSC will perform a normal

shutdown.

• Alarm Module Communication : The GSC can

transmit the fault and alarm conditions to an alarm

module (AM).

• Power Down: The EMCP II system is designed

to remove power from the GSC when the engine

control switch (ECS) is in the OFF/RESET mode

and when the proper jumper wire is removed. The

GSC will not allow the power down until the crank

termination relay and the fuel control relay are

turned off for about 70 seconds. The GSC remains

powered, if the wire is not removed. For the wiring

diagram and the location of the jumper wire, refer

to the Systems Operation, Testing and Adjusting,

SENR5809, “Electronic Modular Control Panel II

(EMCP II) For MUI Engines” or to the Systems

Operation, Testing and Adjusting, SENR5398,

“Electronic Modular Control Panel II (EMCP II) For

EUI Engines”.

• Fuel Solenoid Type : The GSC can be

programmed to work with an energized to run

(ETR) fuel system or to work with an energized to

shutdown(ETS) fuel system.

38

SEBU7125-13

Operation Section

If Equipped

Loading...

Loading...