For additional information on selecting an oil, refer to

Special Publication, SEBU6251, “Caterpillar

Commercial Diesel Engine Fluids

Recommendations”.

Cooling System

To maintain the cooling system, the Total Cooling

System capacity must be known. The approximate

coolant capacity for the engine is shown in Table 13 .

External System capacities will vary among

applications. Refer to the specifications for the

External System capacity. This capacity information

will be needed in order to determine the amount of

coolant/antifreeze that is required for the Total

Cooling System.

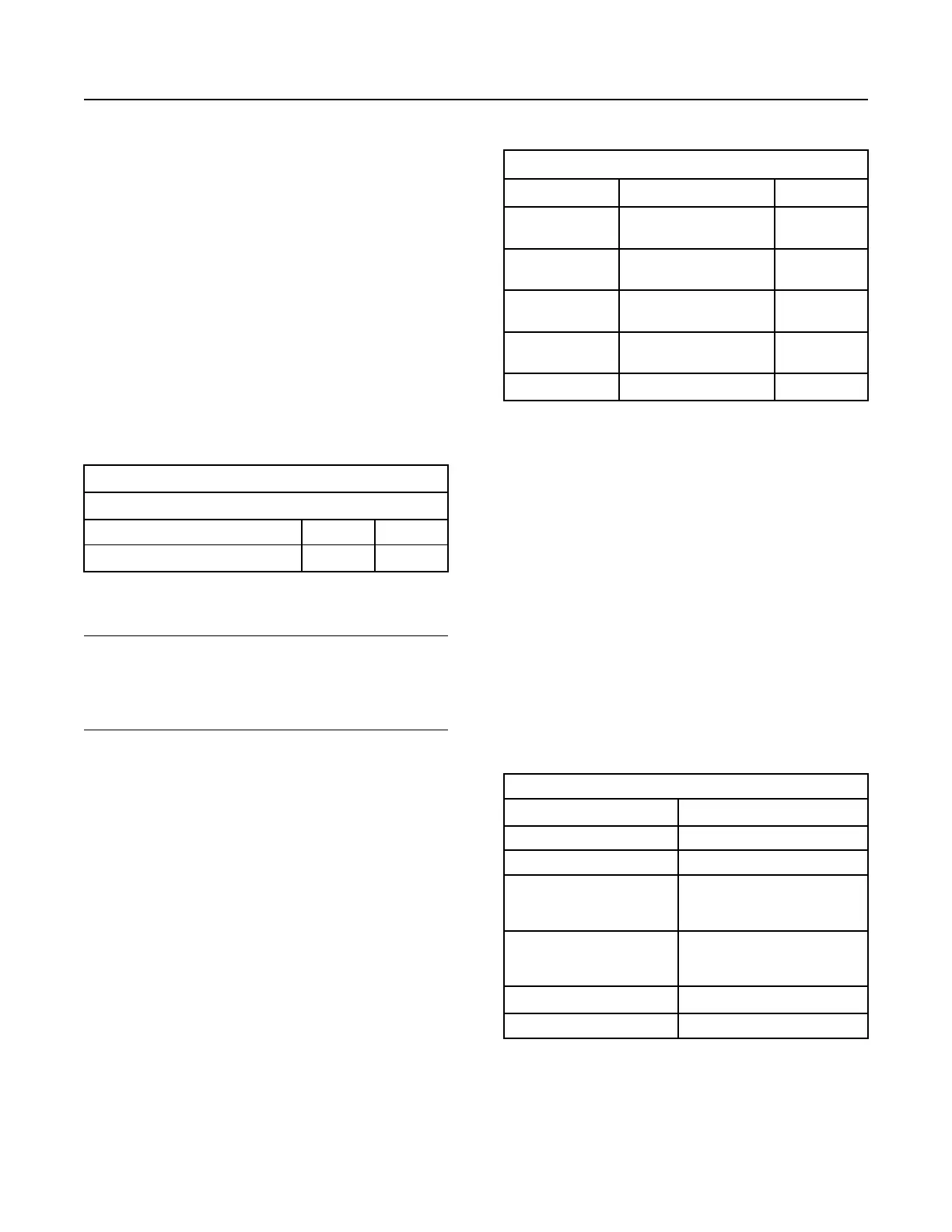

Coolant Capacities

Table 13

3412C Generator Set Engine

Approximate Refill Capacities

Liters Quarts

Engine Only

58 62

Coolant Recommendations

NOTICE

Do not use a commercial coolant/antifreeze that only

meets the ASTM D3306 or D4656 specification. This

type of coolant/antifreeze is made for light duty auto-

motive applications.

The following coolants are the primary types of

coolants that are used in Caterpillar Engines:

Preferred – Cat ELC Extended Life Coolant or a

commercial extended life coolant that meets the

Caterpillar EC-1 specification

Acceptable – Cat DEAC Diesel Engine Antifreeze/

Coolant or a commercial heavy-duty coolant/

antifreeze that meets “ASTM D4985” or “ASTM

D5345” specifications

Caterpillar recommends a 1:1 mixture of water and

glycol. This mixture will provide optimum heavy-duty

performance as a coolant/antifreeze.

Note: Cat DEAC DOES NOT require a treatment with

an SCA at the initial fill. Commercial heavy-duty

coolant/antifreeze that meets “ASTM D4985” or

“ASTM D5345” specifications MAY require a

treatment with an SCA at the initial fill. Read the label

or the instructions that are provided by the OEM of

the product.

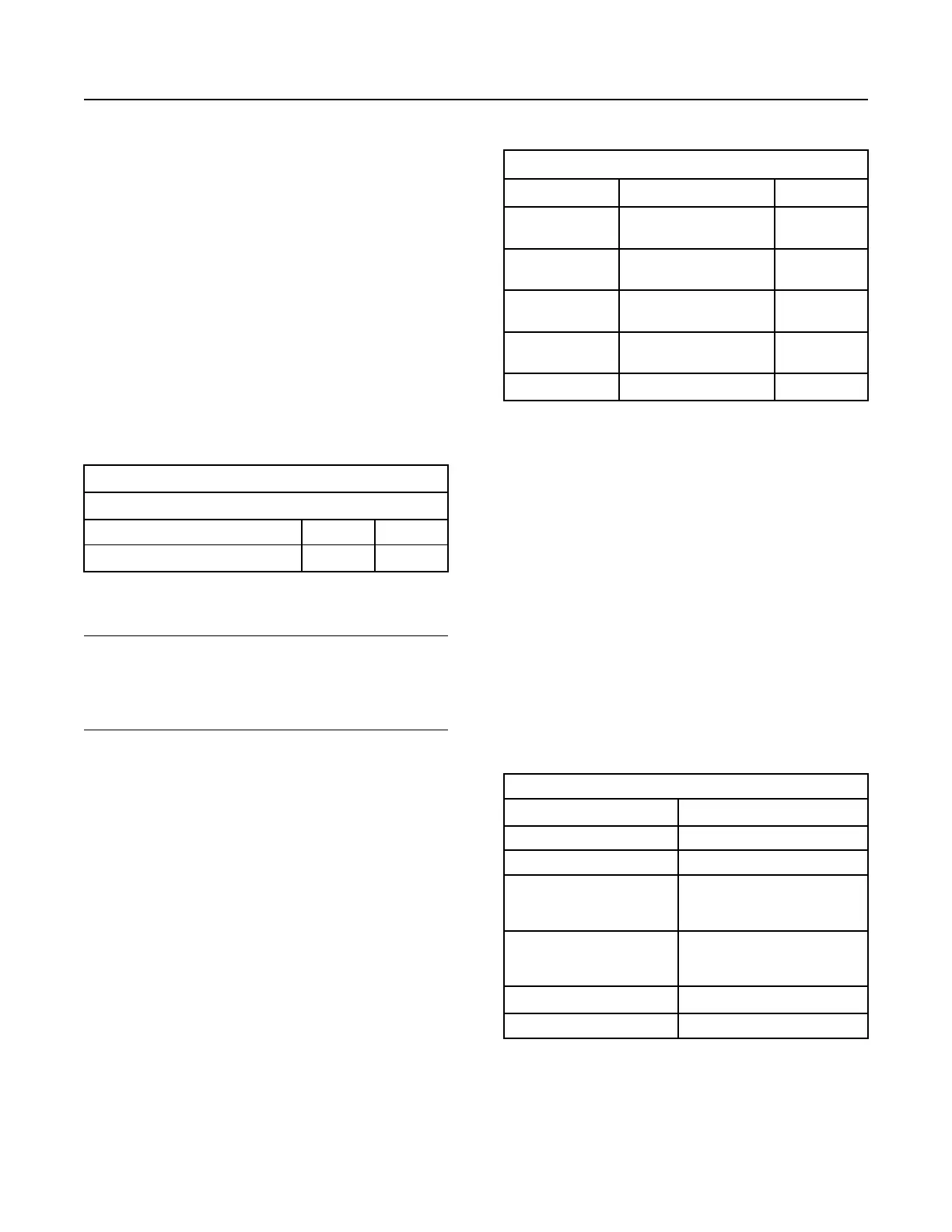

Table 14

Caterpillar Minimum Acceptable Water Requirements

Property

Maximum Limit ASTM Test

Chloride (Cl)

40 mg/L

(2.4 grains/US gal)

“D512”,

“D4327”

Sulfate (SO

4

)

100 mg/L

(5.9 grains/US gal)

“D516”

Total Hardness

170 mg/L

(10 grains/US gal)

“D1126”

Total Solids

340 mg/L

(20 grain/US gal)

“D1888”

Acidity pH of 5.5 to 9.0

“D1293”

In stationary engine applications that do not require

protection from boiling or freezing, a mixture of SCA

and water is acceptable. Caterpillar recommends a

minimum of six percent to a maximum of eight

percent SCA concentration in those cooling

systems. Distilled water or deionized water is

preferred. Water which has the required properties

may be used. For the water properties, refer to

Special Publication, SEBU6251, “Caterpillar

Commercial Diesel Engine Fluids

Recommendations” for additional information that

relates coolant.

Note: The service life of coolant is limited by use of

service hours. Refer to the specific engine's

Operation and Maintenance Manual, “Maintenance

Interval Schedule” (Maintenance Section). To

achieve this service life, the coolants must be

properly maintained. The maintenance program

includes S·O·S coolant analysis.

Table 15

Coolant Service Life

Coolant Type

Service Life

(1)

Cat ELC Six Years

Cat DEAC Three Years

Commercial Heavy-Duty Cool-

ant/Antifreeze that meets

“ASTM D5345”

Two Years

Commercial Heavy-Duty Cool-

ant/Antifreeze that meets

“ASTM D4985”

One Year

Caterpillar SCA and Water

Two Years

Commercial SCA and Water One Year

(continued)

SEBU7125-13

97

Maintenance Section

Refill Capacities and Recommendations

Loading...

Loading...