13

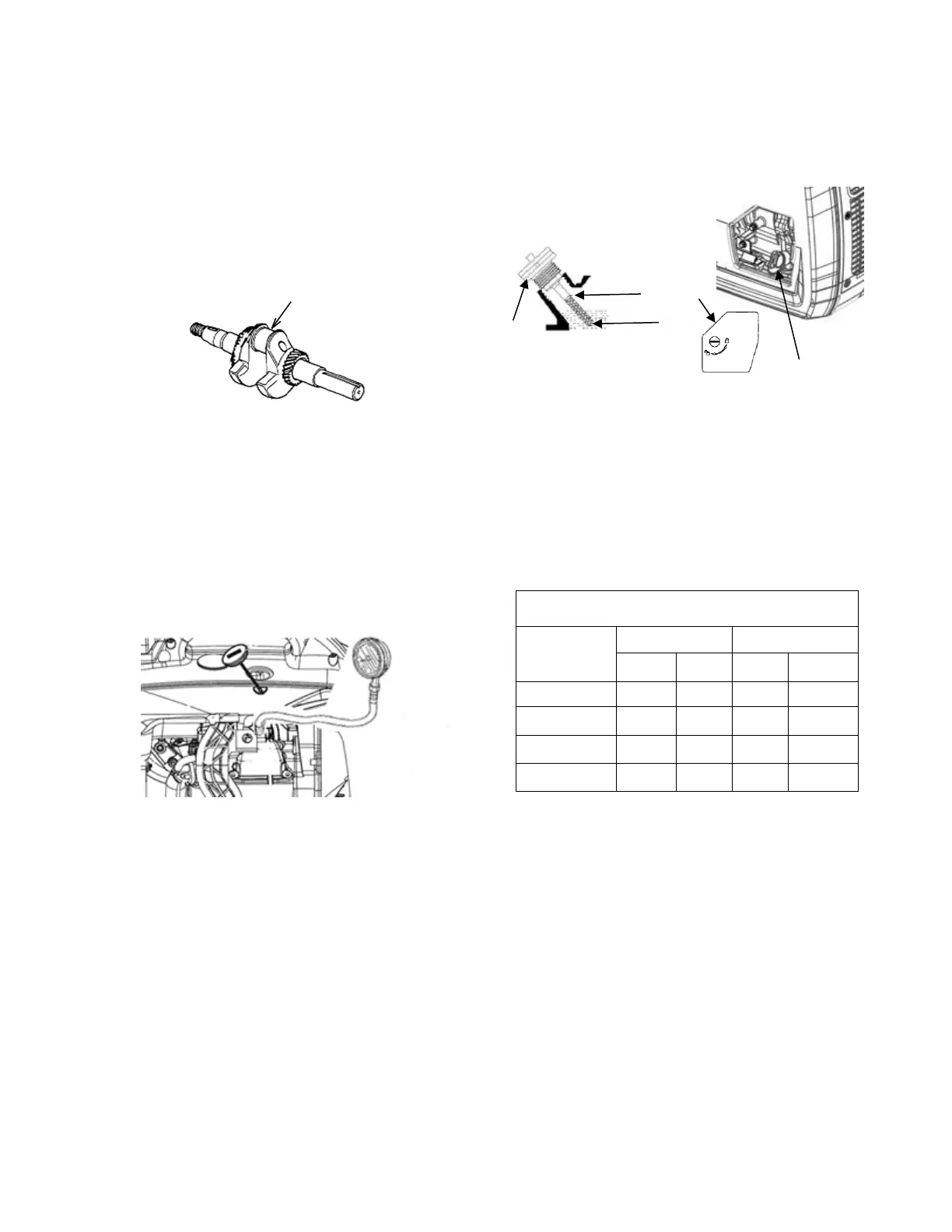

Crankshaft – Inspect/Replace

Inspect the crankshaft oil seal. If the seal is

damaged or shows sign of leakage, replace the

seal.

Inspect the crankshaft bearings. If the bearing is

scored or shows signs of discoloration from

excessive heat, replace the bearing. Coat the

bearing with engine oil before installing.

Check the diameter of the crankshaft journal (1).

A normal diameter is 21.97-21.98mm. If the

diameter is 21.87mm or less, replace the

crankshaft.

When installing the crankshaft, insert it into the

crankcase until the bearing touches the

crankcase without damaging the oil seal.

Cylinder Pressure – Check

Remove the side panel (side with service

access doors) by removing the 2 bolts and

lifting out and away (be careful to avoid

breaking the locating tabs).

Remove the spark plug boot and spark

plug.

Connect the compression gauge as shown

above.

Pull the recoil starter handle several times

and note the cylinder pressure.

If the cylinder pressure is not greater than

or equal to 0.95 MPa (138 psi), refer to the

Troubleshooting section.

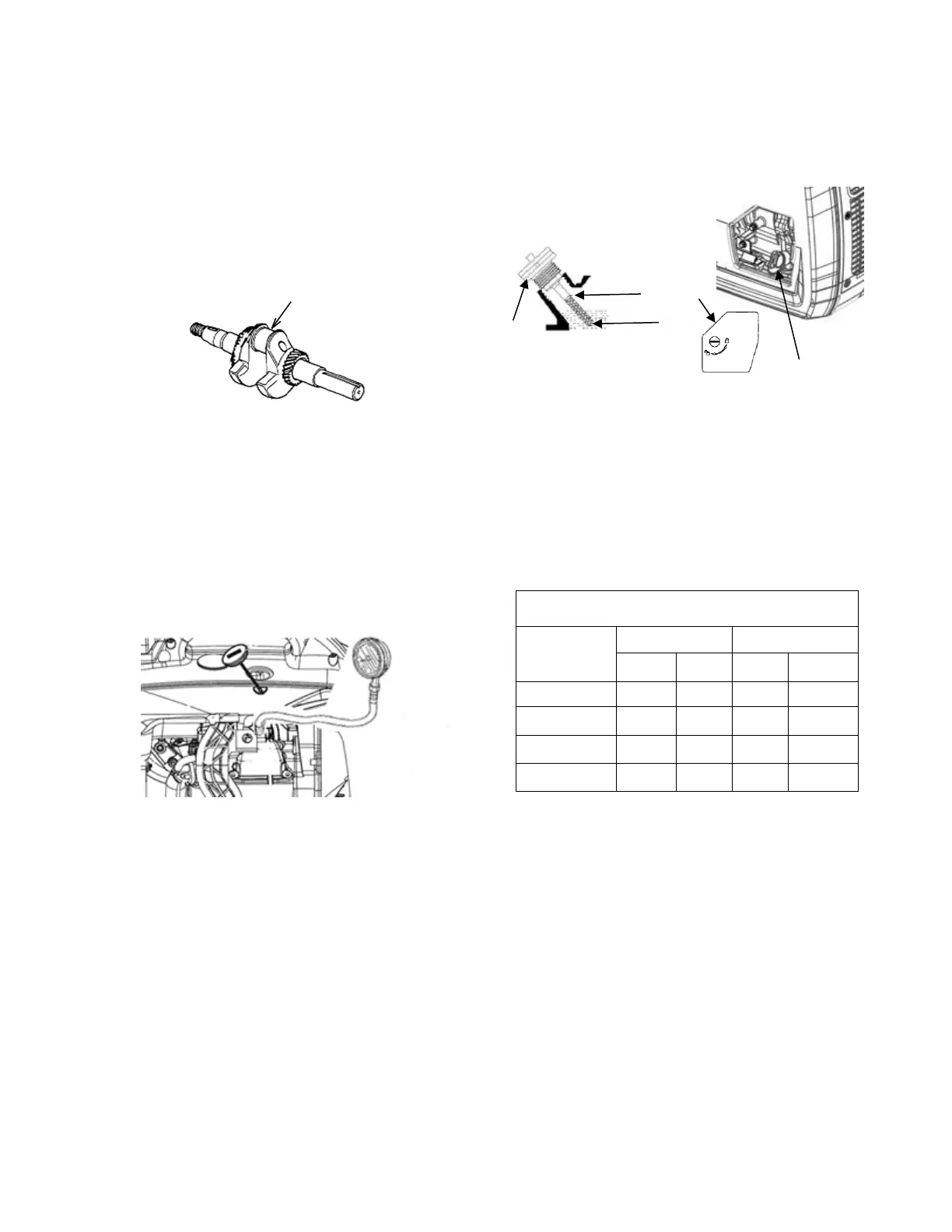

Engine Oil Level – Check

Always check the engine oil with the generator

on a level surface and with the engine stopped.

1.

Open the right service door (1). Remove the

oil level gauge (2) and wipe clean.

2.

Check the oil level by re-inserting the oil level

gauge (do not screw in tight).

3.

If the oil level is low (4), add the

recommended engine oil, using the funnel

supplied, until the oil level reaches the upper

mark (3) on the oil level gauge. Use the chart

below to determine which viscosity oil to use.

4.

After adding oil, install and tighten the oil

level gauge (2), and close the service door

(1).

Note: Non-detergent and 2-stroke engine oils will

damage the engine and

must not be used.

Recommended Lubricant Viscosities for

Ambient Temperature

Loading...

Loading...