15

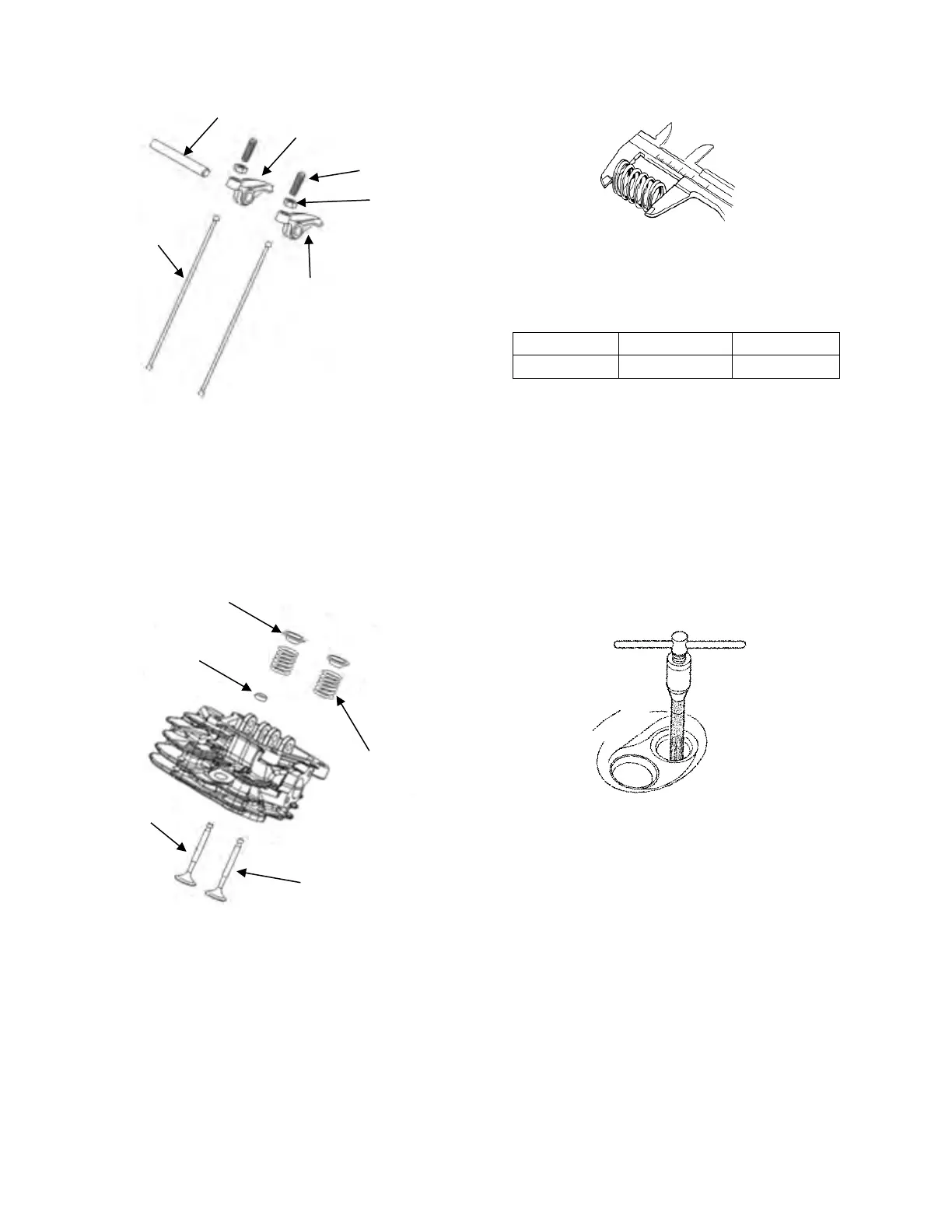

Remove locking nut (2) and adjusting nut (1).

Remove shaft (5), and remove exhaust valve

rocker arm (6). Repeat the process for intake

valve rocker arm (3). Check the rocker arms for

wear. Replace if damaged. Remove pushrods

(4). Inspect the pushrods. Make sure they are

straight and not scored. Check the pushrod ends

for wear. Replace the pushrods if worn or

damaged.

Note: Do not remove the retainer (1) while the

head is still on the engine or the valves will drop

down into the cylinder.

Press down on retainer (1) and move it to the

side so that the valve stem will pass through the

larger hole. Remove valve spring (2) and

exhaust valve (4). Repeat the process for the

intake valve (3) and retainer.

Valve Springs:

Check the free length of the valve spring. The

normal free length is 28.5mm. If the free length

is 25.5mm or less, replace the spring.

Valve Guides:

Inspect the valve guides. Make sure that they fit

tightly into the cylinder head. Inspect the inner

surfaces of the valve guides. The inner surface

should be smooth, with no cracking or pitting. If

the inner surface is damaged, replace the valve

guide.

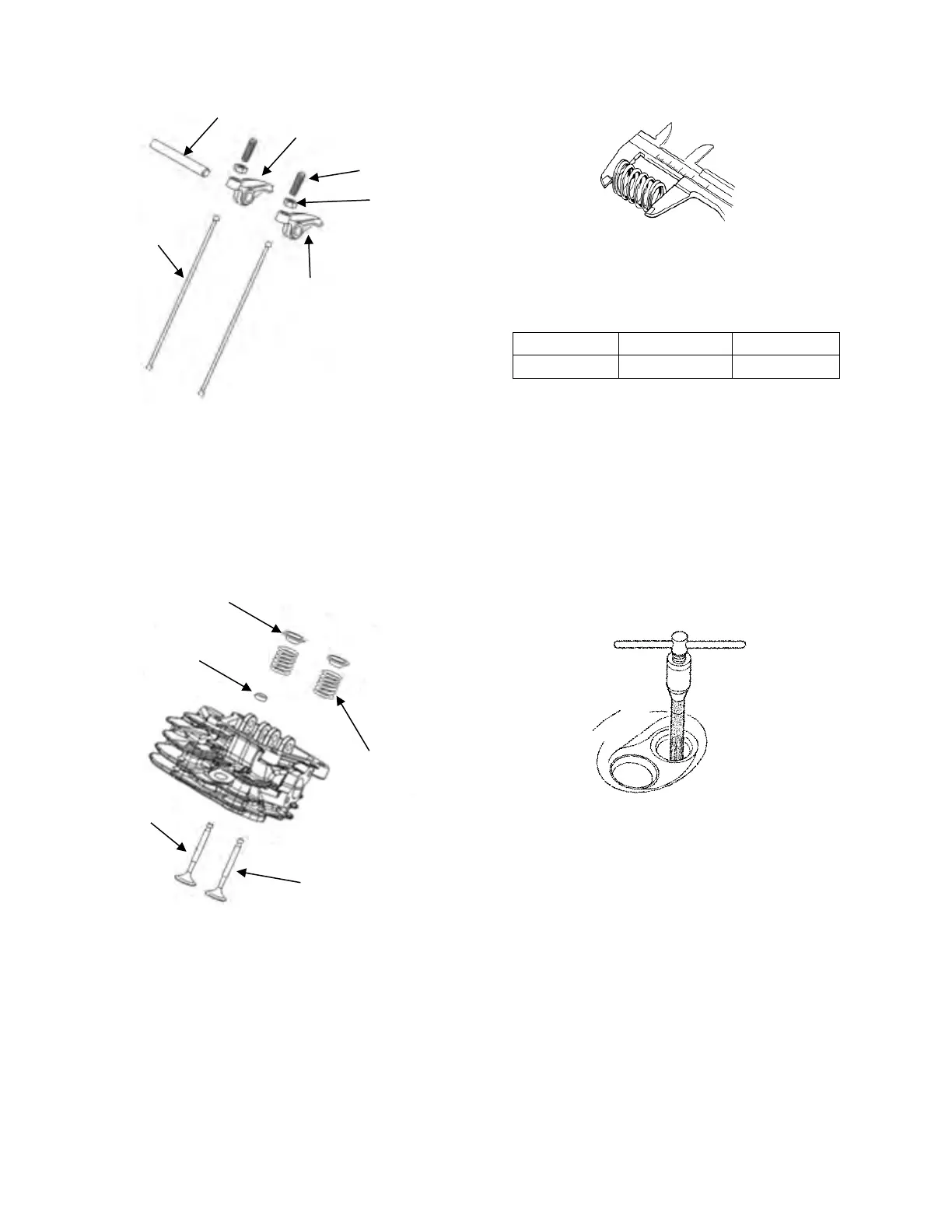

Valve Guides – Ream:

For best results perform this procedure when the

valve guides and cylinder head are at room

temperature.

Make sure that the reamer is centered over the

valve guide. Coat the reamer and valve guide

with cutting oil. Turn the reamer clockwise and

work it through the valve guide for the entire

length of the reamer. Continue to turn it

clockwise as you remove the reamer from the

valve guide. Remove any carbon deposits and

check the internal diameter of the valve guide.

The normal diameter of the valve guide is

8.6mm. If the internal diameter of the valve

guide is 9.021mm or more, either replace the

valve guide or install inserts.

Loading...

Loading...