16

Check the valve guide bore. Insert the valve and

make sure that it moves smoothly through the

bore without any wobble. Figure 1 shows a good

valve guide. Figure 2 shows a valve guide with

abnormal wear that would allow the valve to

wobble. The valve head could eventually break

off and fall into the combustion chamber,

damaging the engine. This valve guide must be

reamed or replaced. Figure 3 shows a valve

guide with a bore that is not centered. This valve

guide must be replaced.

Valve Guides – Replace:

Place the new valve guides in the freezer

compartment of your refrigerator for one hour.

Use a valve guide driver to drive out the old

valve guides. Take care that you do not damage

the cylinder head while driving out the old valve

guides.

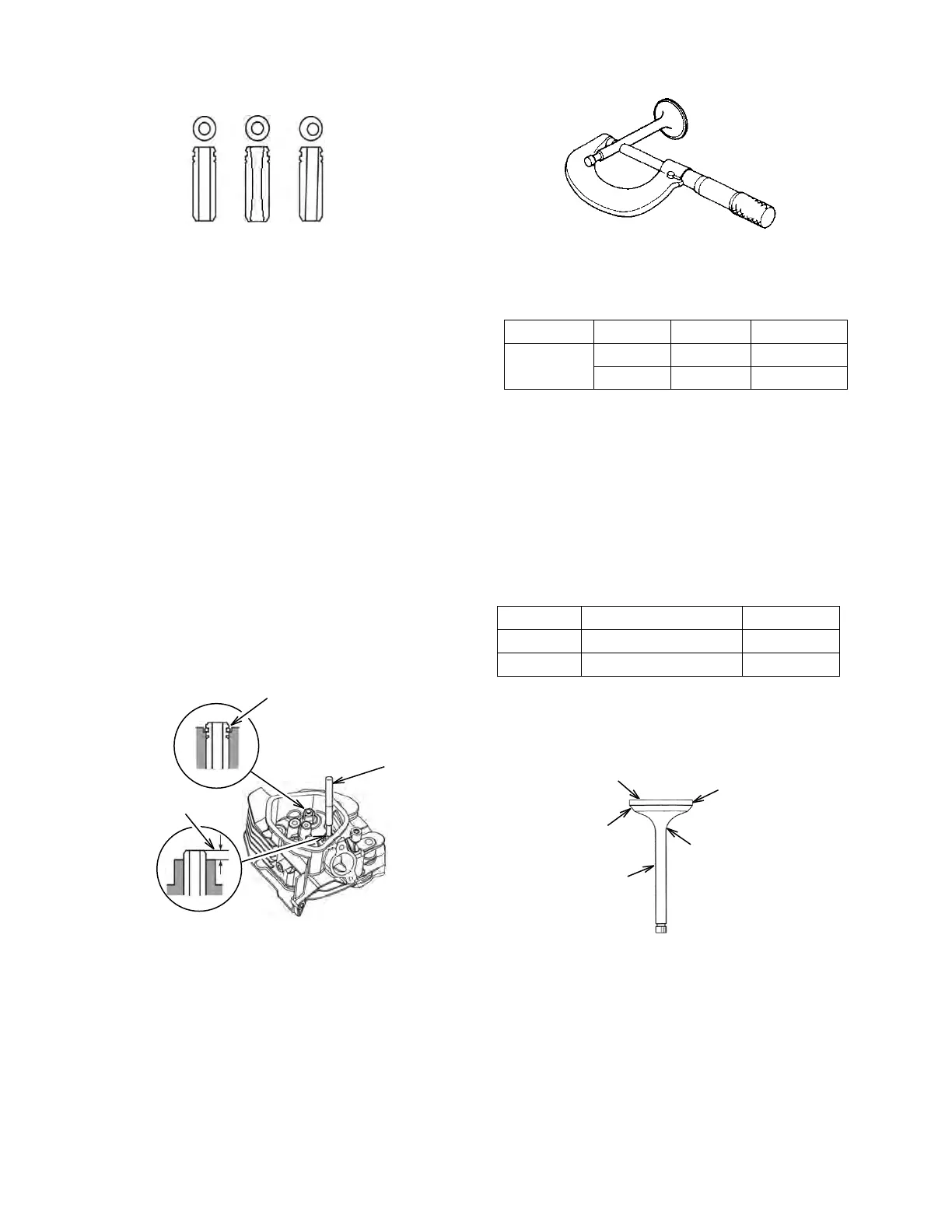

Install the new valve guides from the valve

spring side of the cylinder head. Use the valve

guide driver (2) to drive the exhaust valve guide

in until the clip is fully seated (1). Drive the

intake valve guide in until the top of the valve

guide extends 1mm above the cylinder head (3).

After installation check each valve guide for

damage. If damaged, repeat the removal and

installation process using a new valve guide.

Use a micrometer to measure the outside

diameter of the valve stem. Refer to the

following table.

If the diameter of the valve is at or below the

minimum, replace the valve.

Subtract the diameter of the valve stem from the

internal bore of the valve guide to determine the

valve stem-to-guide clearance. If the clearance

is more than the maximum shown in the

following chart, determine if a new guide or a

new valve is the best choice to bring the

clearance back into tolerance.

Valves:

Check the valves for damage. Check the valve

head (1), valve margin (2), and valve face (3) for

damaged or burnt areas. Check the valve neck

(4) for unusual wear. Check the valve stem (5)

for wear, scoring, or bends. If any damage is

found, replace the valve.

Loading...

Loading...