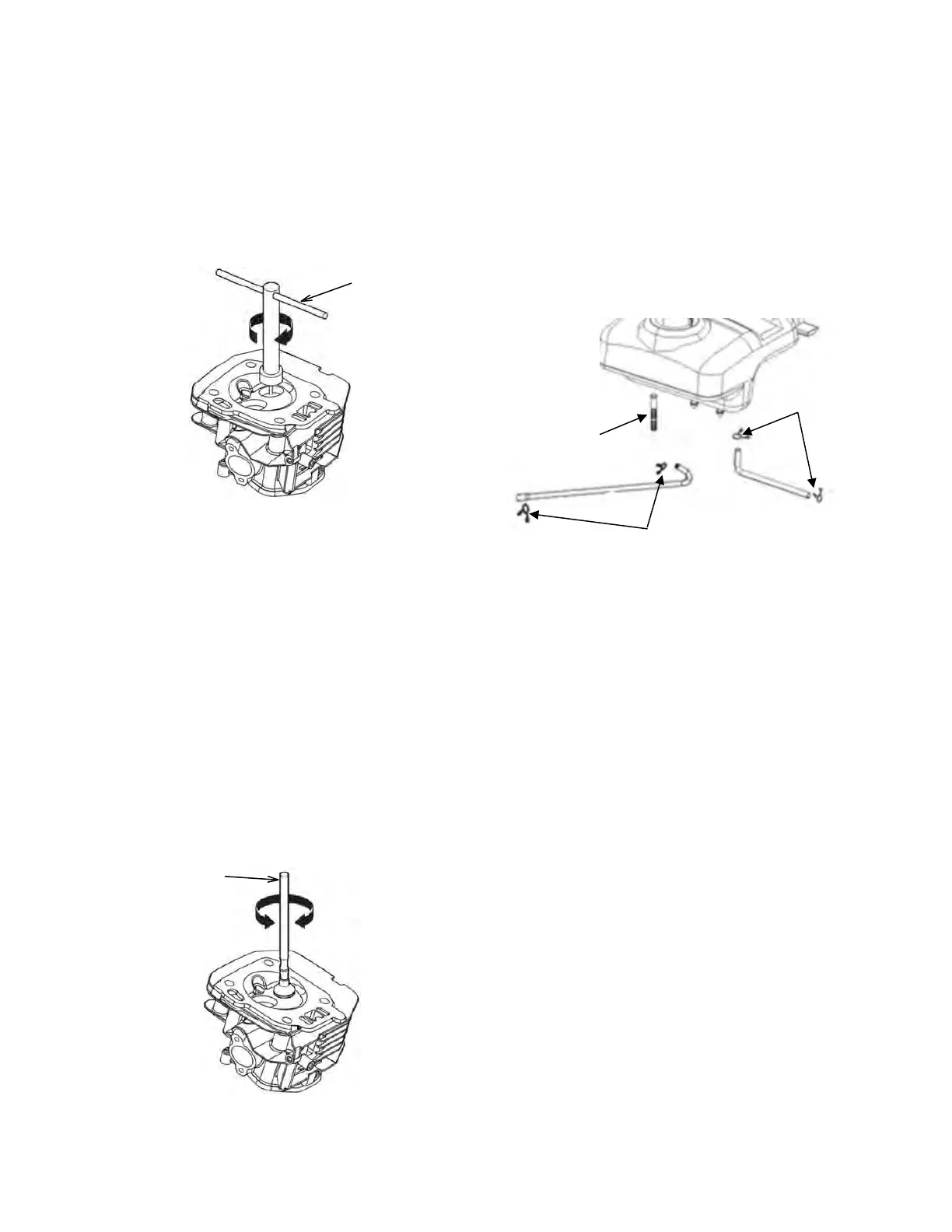

17

Remove any carbon deposits from the valve

seats. Use a runout gauge to measure the

concentricity of the seat. Alternatively, apply a

light coat of a marking compound to the valve

face and insert the valve into the head. Press

the valve in firmly and then remove the valve.

Check the paint for signs that the valve seat is

not concentric. Remove the marking compound

from both surfaces.

If the marking compound shows that the valve

seat is not concentric, use a 45° valve seat

cutter (1) to produce a smooth, concentric seat.

Always turn the cutter clockwise. Use both the

45° valve seat cutter and the 32° valve seat

cutter to adjust the valve seat so that it contacts

the middle of the valve face. The 32° valve seat

cutter removes material from the top of the seat.

The 45° valve seat cutter removes material from

the bottom of the seat. Be sure that when

finished the area where the valve contacts the

valve seat is from 3.3 to 3.7mm wide. To

complete the procedure, make a light pass with

the 45° valve seat cutter to remove any burrs

that may be on the edge of the seat. When

complete, use the marking compound to check

for concentricity. Make sure that there is good

contact all the way around the valve.

Apply lapping compound to the valve face and

insert the valve into the cylinder head. Use a

valve lapping tool (1) to finish surfacing the valve

and valve seat. Remove any remaining

compounds before assembling the cylinder

head. Make sure that the pushrods are firmly

seated in the lifters. After assembly, follow the

Engine Valve Lash – Adjust and the Cylinder

Pressure – Check procedures to ensure a

proper assembly.

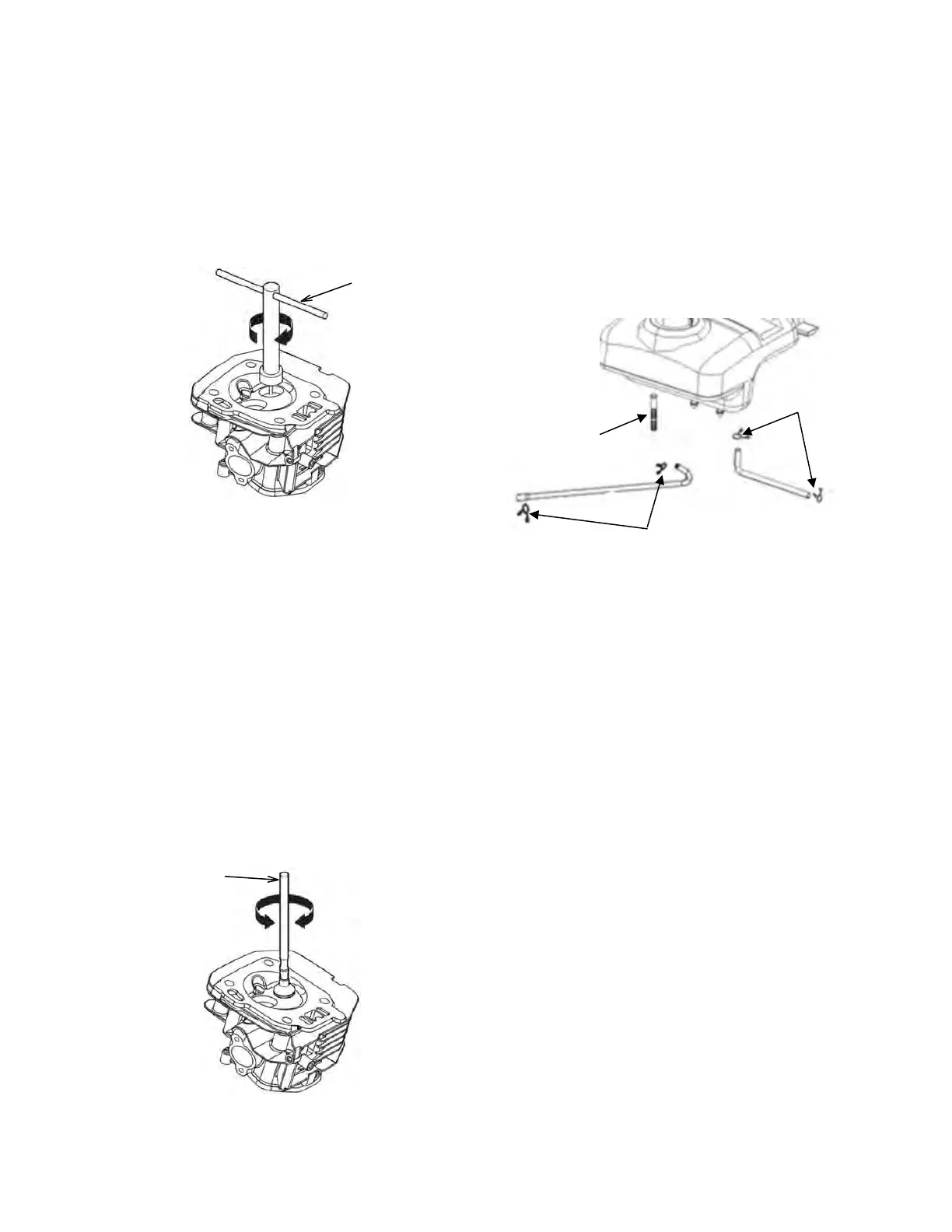

Fuel Line and Filter – Replace

Drain the fuel from the fuel tank into an

appropriate container. Start the engine and let

the engine run out of fuel. Turn the generator

switch to the off “0” position.

Remove the side panel (side with service access

doors) by removing the 2 bolts and lifting out

and away (be careful to avoid breaking the

locating tabs). The fuel tank does not need to be

removed to replace the fuel line. Move clamps

(1) to the center of the fuel line.

Remove the fuel line from the fuel filter (2).

Remove the fuel filter. Wipe the mounting

surface with a clean rag and install a new fuel

filter. Tighten the fuel filter.

Remove the fuel line from the rear of the

generator switch and the carburetor.

Inspect the clamps. If the clamps are damaged

discard the old clamps and use new clamps.

Place two clamps near the center of each new

fuel line and install the fuel lines. Position the

clamps so that they will hold the fuel line

securely in place.

Loading...

Loading...