Setup and Operation Page: 9 Installation Step-by-step instructions for properly installing the sterilizer, including placement, ventilation, and electrical connections.

First Use Guide on the initial setup and operation of the sterilizer, including water filling and basic power-on procedures.

General Instructions Comprehensive operational guidelines covering power switch, door operation, water tank filling, and general usage tips.

Demineralised Water Instructions and warnings regarding the use of demineralized water, its quality, and potential damage from improper water usage.

Stand-By Function Explanation of the standby function, its activation, and power-saving benefits.

Delayed Start Description of the delayed start function, its purpose, and how to set a delayed cycle start time.

Drying Function Explanation of the drying function, detailing the different drying options available (Normal, Double, Without Drying).

ECO Function Explanation of the ECO function for optimizing power consumption and cycle life by adjusting time and load.

USB - Disk Function Description of the USB function for synchronizing cycles between the appliance and a USB flash drive.

Printer Function (Optional) Information on using the optional printer function for printing cycle data, such as the last cycle or recent history.

Maintenance Overview Information on accessing the maintenance schedule and contacting a technician for planned upkeep.

Key Components and Tests Page: 18 Anti-Bacteria Air Filter Importance and maintenance of the anti-bacteria filter for sterility and proper chamber pressure balance.

Manometer Explanation Explanation of the manometer's role in indicating chamber pressure and vacuum, and troubleshooting pressure issues.

Test Cycles Overview Description of test cycles, including Helix Test, Bowie & Dick Test, and Air Leakage Test, for verifying appliance operation.

Cycle Type Use Modes Overview of different cycle types (B and S) and their intended uses and compatible material types.

Sterilizing Cycle Details Table detailing various sterilizing cycles, their material types, temperatures, times, and drying options.

Load Recommendations Guidelines for loading instruments and materials into the sterilizer for optimal steam penetration and sterilization.

Max Charge Table Table specifying the maximum load capacity for different materials and cycle types for SST 1700 and SST 2200 models.

Maintenance and Troubleshooting Page: 22 Spare Parts List List of common spare parts with their codes and descriptions, for maintenance and replacement.

Routine Maintenance Procedures Instructions for regular maintenance tasks, including cleaning, seal checks, filter replacement, and safety valve checks.

Chamber Cleaning Guidelines for cleaning the sterilizing chamber and its internal components regularly.

Cleaning Instructions Detailed instructions for cleaning the sterilizer's exterior, interior, and touch screen, using appropriate cleaning agents.

Warranty Information Information regarding the warranty coverage for the sterilizer, including limitations and terms.

WEEE Instructions Guidelines for the disposal of electrical and electronic equipment waste according to EU directives.

Standards Tables (EN 13060) Tables outlining maximum advisable limits for contaminants in feed and condensate water for steam sterilization.

Troubleshooting Guide Guide to diagnose and resolve common faults and issues with the sterilizer, including fuse checks and thermostat reset.

Alarms Table A comprehensive table listing all possible alarms, their probable origins, and recommended solutions for resolving them.

Alarm 98: Black-out Troubleshooting for alarm 98: power interruption (black-out) occurred during operation.

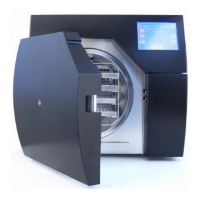

Technical Specifications Page: 28 Specifications Overview Technical specifications for SST 1700 B and SST 2200 B models, including dimensions, capacity, power, and materials.

Integrated Printer Details Details about the optional integrated printer, including paper specifications, print method, and description of its parts.

Paper Replacement Instructions for replacing the paper roll in the integrated printer.

Printer Keys and LEDs Explanation of the printer's keys and LEDs, including their functions and status indicators.

Safety Data Table A table summarizing safety-related data, including fuses, terminals, specifications, and pressure vessel details.