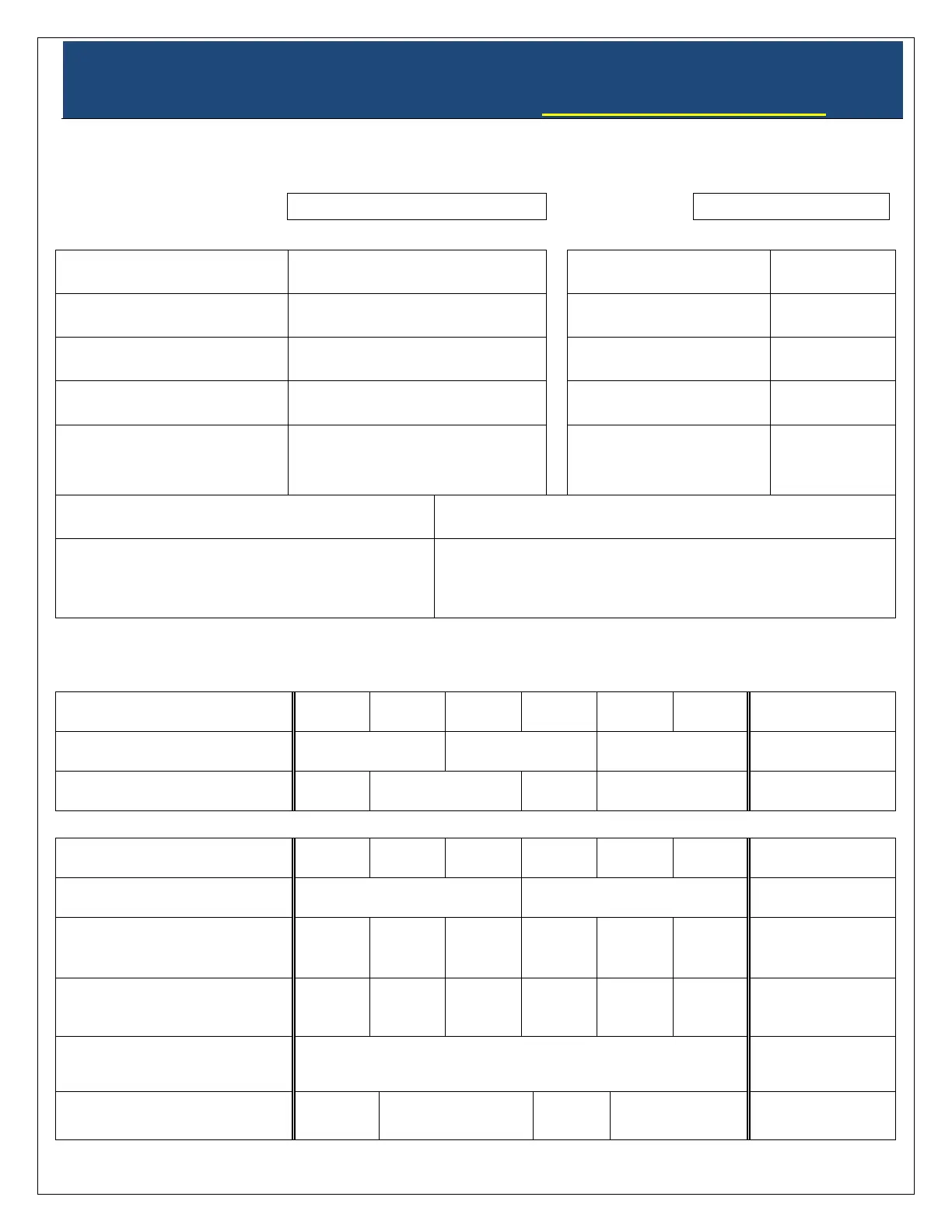

58 V8.18

CellarPro Split Systems must be installed by an experienced professional in adherence with industry practices

and as described in the manual. If you need technical assistance during the installation, call 877.726.8496 x2.

Please provide the email address to contact with the warranty activation_______________________________

Technician Name Tech Phone

System Information Piping Information

Customer Name R-134a System Charge(lb)

Condensing Unit Model # Line-set Length (ft)

Condensing Unit Serial #

Liquid line diameter (OD)

Evaporator Model #

Suction line diameter (OD)

Evaporator Serial #

Trap installed in drain line,

charged with water, and

tested for drainage (Y/N)

Power to Condensing Unit (Check One) ____From Evaporator ____From External Source

Power to Compressor Heater (Check One)

- 3000S – 8000S Split Systems

- AH6500 / AH8500S Split Systems

____No Heater ____ Wire “L1” ____Wire “C”

____No Heater ____ Terminal “L1” ____ Terminal “K”

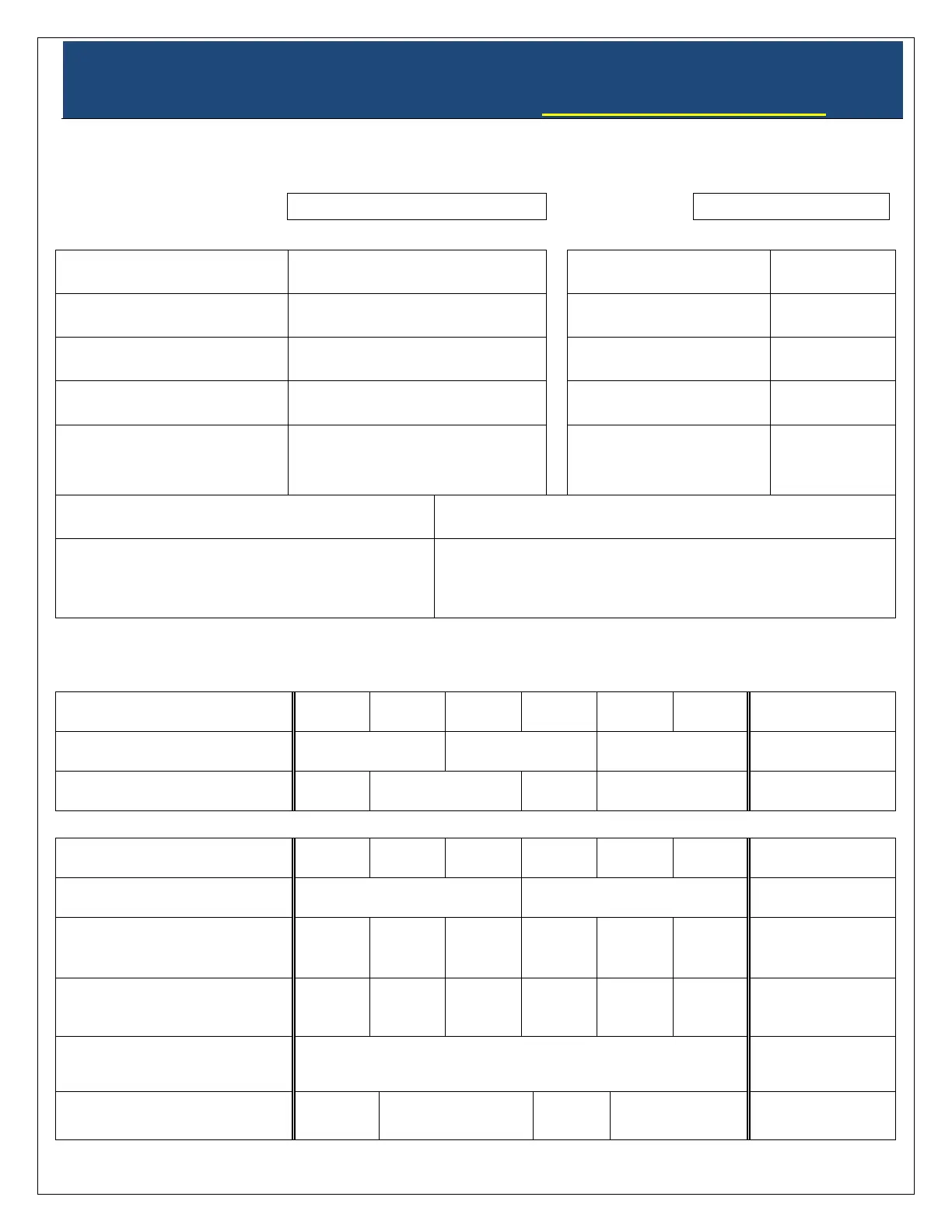

Operational Data: Take the following measurements during a normal refrigeration cycle, once the cellar has pulled down

to the set-point temperature. Make sure the compressor is running when recording the data.

Evaporato

Ran

e

Air temp. at Evap coil (°F) Inlet Outlet TD 8-10°F TD

Evap Fan Speed (Check One) __ High __ Med __ Low

Evaporator power supply Volts Amps

103-127V

nameplate amps

Condensin

Unit

Air temp at Condenser coil (°F) Inlet Outlet TD 20-30°F TD

Condenser fan status __ On __Off

Suction readings at access

valve

PSIG °F SH

25-35 PSIG

20°F Min.

Superheat

Liquid readings at access valve PSIG °F SC

105-180 PSIG

10-20°F

Subcooling

Initial Refrigerant Charge

Through (Check One)

___ Suction Access Valve ___ Liquid Access Valve

Condensing unit power supply Volts Amps

103-127V

nameplate amps

**REQUIRED** TO ACTIVATE THE WARRANTY.

INSTALLERS MUST FILL OUT THIS SHEET AND FAX TO

707.794.8005 OR SCAN & EMAIL TO INFO@CELLARPRO.COM

Loading...

Loading...