Centroid Acorn Plasma Users Manual Beta CNC12 v4.65 rev6

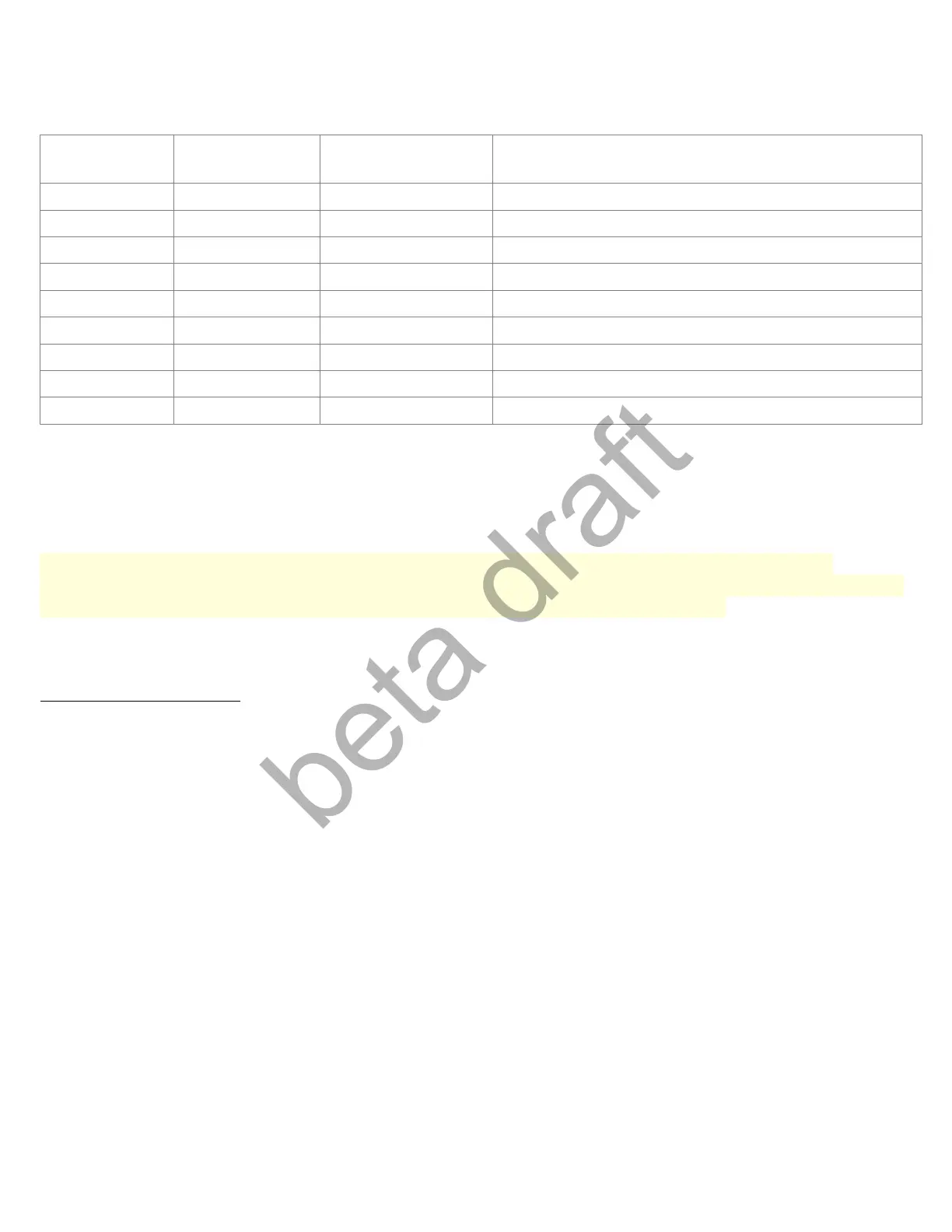

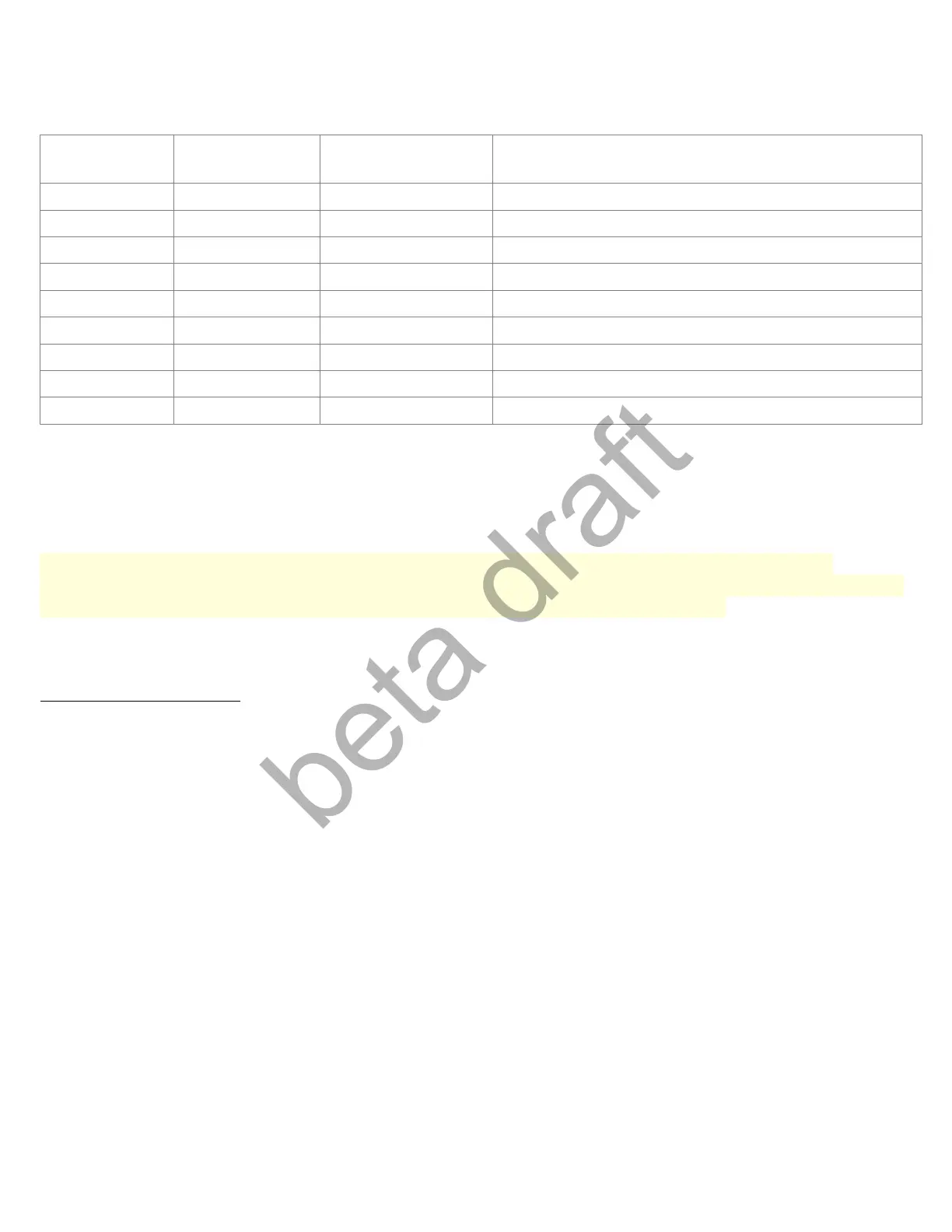

Default Centroid Plasma Smoothing Values (inches)

Parameter # Contouring

Plasma

Precision

Plasma

Description

221 2 10 NBpts

222 .005 .002 Step

223 1000 1000 Umax

224 0 0 Centripetal

226 1 20 W

227 95 20 Minimum Angle

228 0 0 S Curve

230 .5 1 Curve Feedrate Multiplier

231 .25 1 Acceleration Multiplier

See Mill operator manual pages for more information on the Centroid Smoothing menu. Page 332-338

and 222-223

Note: Smoothing works amazingly well BUT, only when the machine has been mechanically and

electronically designed and configured properly in the sweet spot for Plasma use. Smoothing will NOT fix

mechanical problems or improper axis motor/drive configuration, tuning, sizing, etc.

Plasma Machine Setup Sweet Spot for nice cuts and smooth action.

Mechanical Sweet Spot.

1.) Overall Turns ratio value in the range of 1 to 2 turns per inch. Mechanically build the machine so that

one turn of the axis motor yields 1” of travel (25mm) or less. All rack and pinion driven machines will

require a belt reduction or gear box to achieve this. Typically in the 3:1 to 5:1 range depending on the rack

and pinion chosen. Note: Direct driving the pinion with the axis motor results in poor cuts.

Review this post for more information on the Overall Turns Ratio.

2.) Motors sized properly to move the machine without risking losing steps or stalling.

3.) Free and easy axis motion with no sticky spots or other problems, when the axis motor is disconnected

moving the axis back and forth by hand should be smooth, consistent and easy.

4.) Machine is rigid enough not to shake or flex when moving at typical cutting speeds.

Page 40 D:\Keith Documents\centroid_acorn_plasma_users_manual_draft27.odt rev27 3-15-22

Loading...

Loading...