4-8

Maintenance and Care

3) Maintenance

Checking the drive axle

1. Repair and replacement of parts

Inspect drive axle parts such as

seals and washers for wear. If

excessive wear or leakage is

found, these parts need to be

replaced.

Replace seriously worn parts

even if they have not completely

failed.

Steel parts such as shafts or

gears cannot be repaired. If

worn or damaged, they should be replaced.

Seals and washers need to be periodically replaced. Fasten-

ers with auto-locking patches can be reused several times, but

they should have a drop of heavy duty thread locker applied.

The repair of drive axel housing is limited to the removal of

scratches of burrs on the machined surface, or replacement of

damaged studs. Reuse and repair of worn parts should be

avoided. Replacement with new parts is usually more cost

effective and result in less machine downtime than risking

replaced failure of a used part.

When parts replacement is needed, only genuine CLARK ser-

vice parts should be used to maintain optimum performance

and service life.

2. Maintenance period

Replacement period of wheel drive axle oil

2,000 hours with 1.8 Quarts (1.7liter) oil volume.

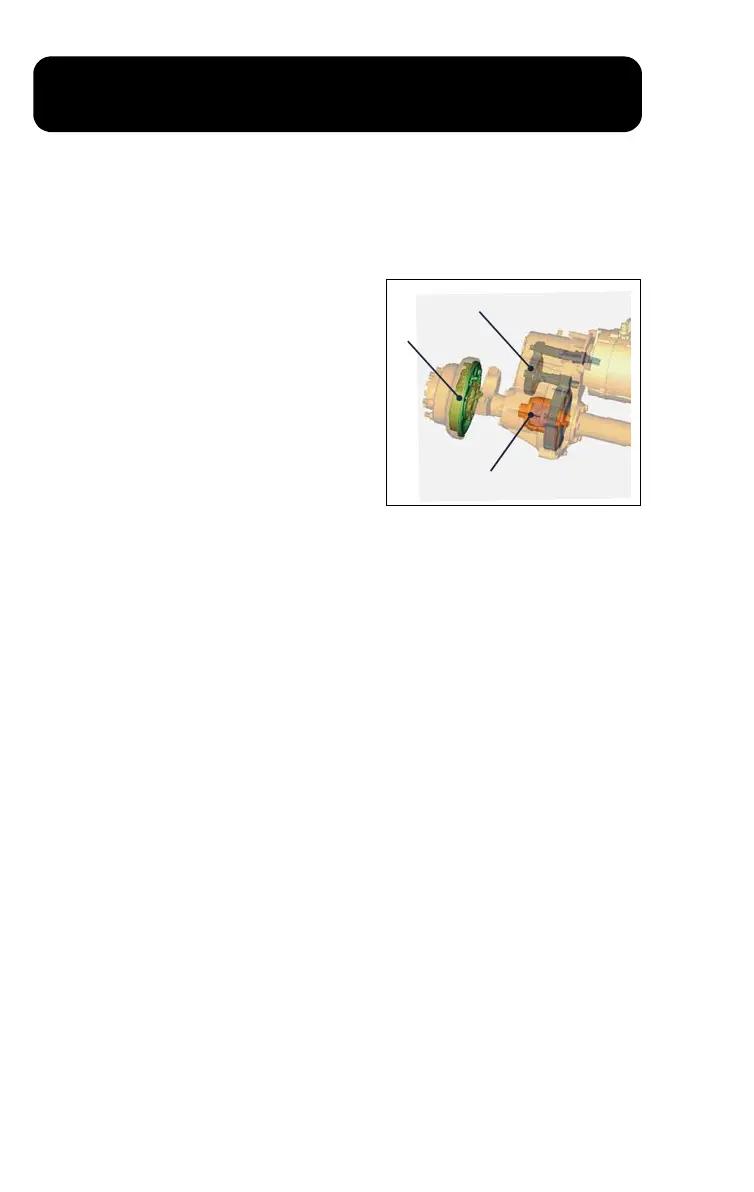

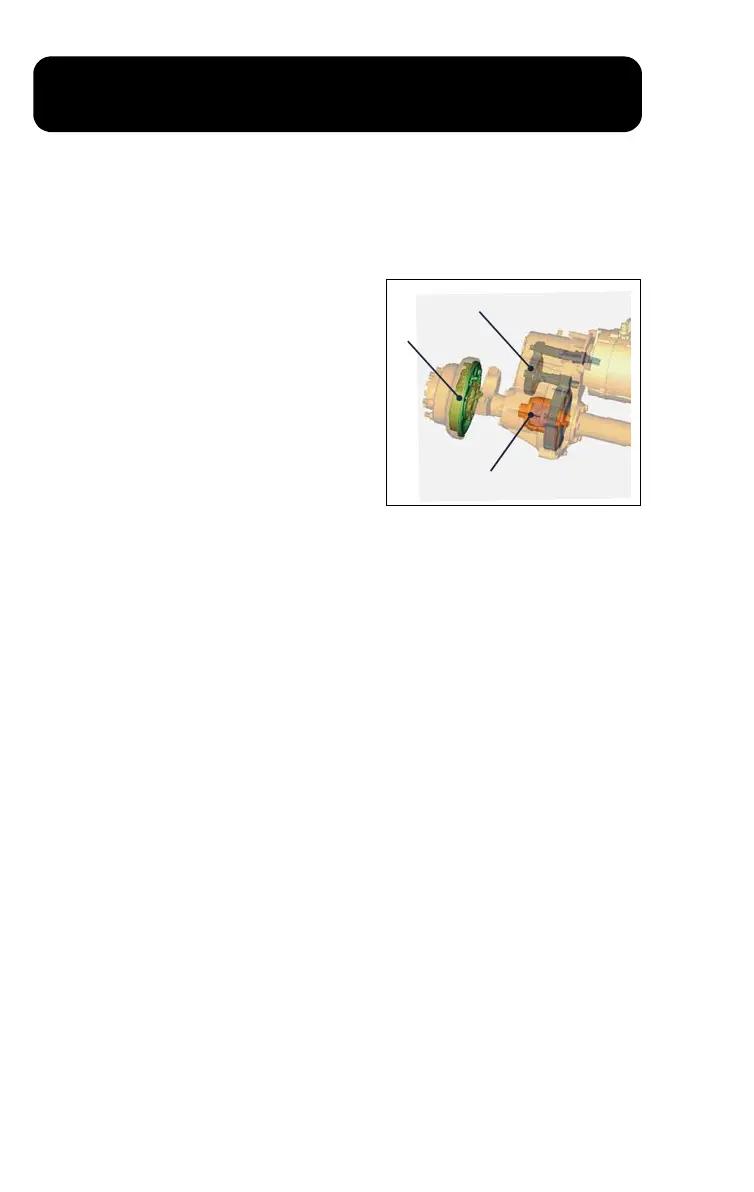

Differential Box

Reduction

Gear

Brake

Loading...

Loading...