4

OPERATING INSTRUCTIONS

If the operation of the chipper becomes sluggish or erratic,

pour one teaspoon of kerosene into the air inlet and

operate the tool for a few seconds. Lubricate the tool as

explained above after flushing.

STORAGE

In the event that it becomes necessary to store the tool for

an extended period of time (overnight, weekend, etc.), it

should receive a generous almount of lubrication at that

time and again when returned to service. Store the tool in

a clean and dry environment. Alternatively, chippers and

scalers may be put in a bucket of kerosene or light oil for

extended periods of storage such as weekends or plant

shutdowns. The tool should always be lubricated before

storage and when being returned to service.

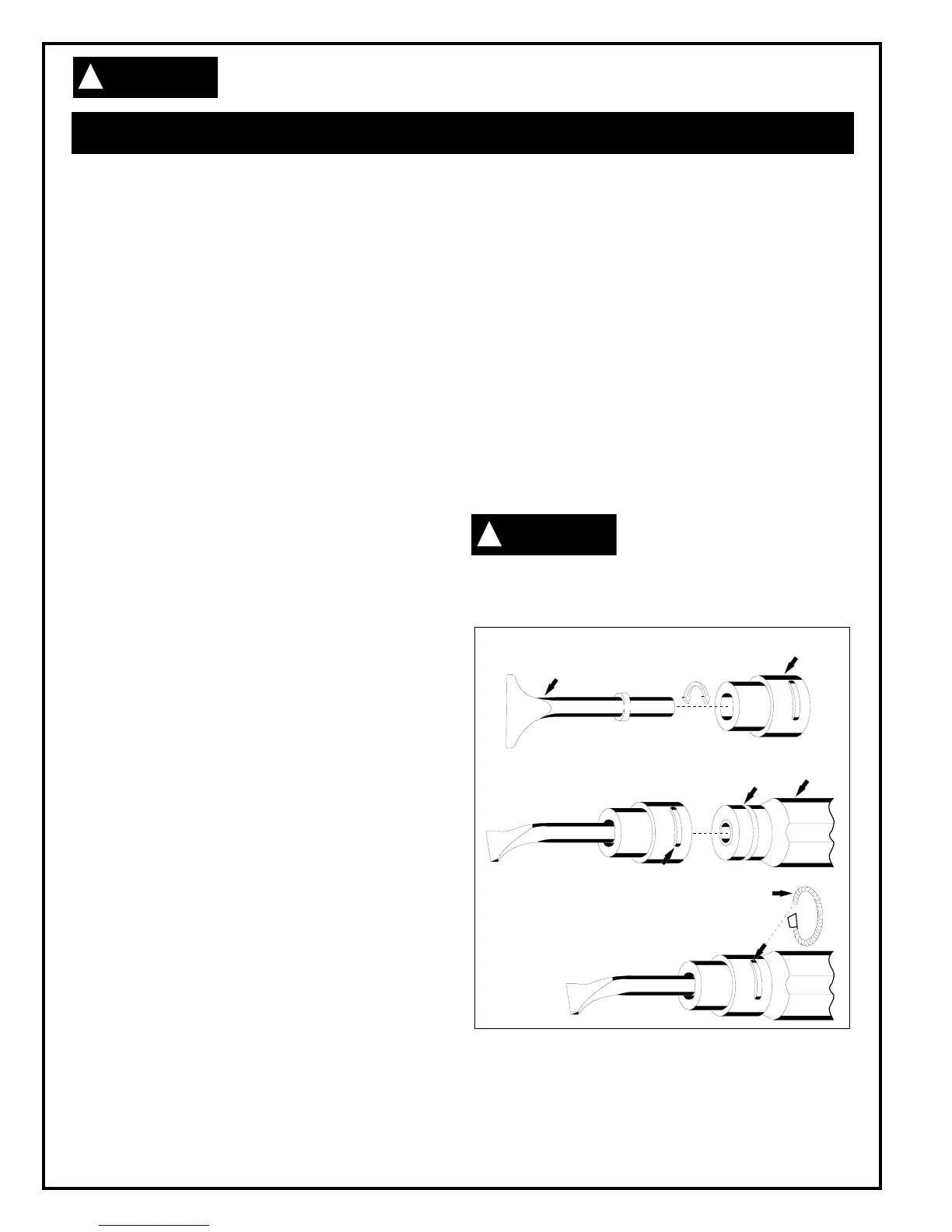

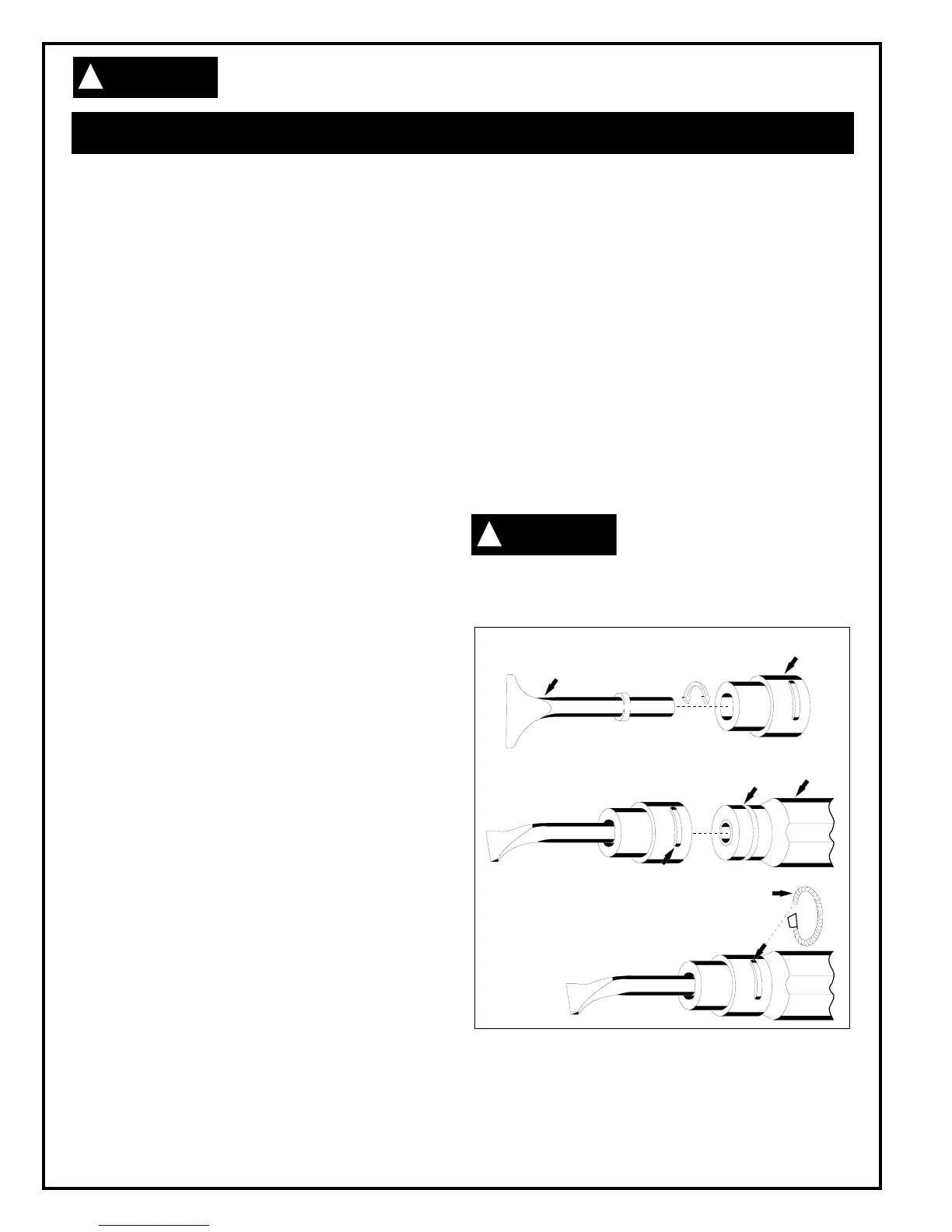

CHISEL INSTALLATION & REMOVAL

Turn off the air and drain the air

hose before installing or removing

any chisel or implement. Follow the

procedure below and on next page for installing any chisel

or implement. Reverse the procedure for removal.

The CLECO "CH" series chipper is designed to operate

on 90 psig air pressure using a 1/2" I.D. hose up to 8' in

length. If additional length is required, a 3/4" I.D. or large

hose should be connected to the 1/2" hose.

The air hose should be cleared of accumulated dirt and

moisture, then one-half (1/2) teaspoon of 10W machine oil

should be poured into the tool's air inlet before connecting

the hose to the tool.

Important: The handle should be checked after the first

eight hours of operation and occasionally thereafter to

make sure it is tight. Torque to 300 ft. lbs.

LUBRICATION

An automatic in-line filter-lubricator is recommended as it

increases tool life and keeps the tool in sustained opera-

tion. The in-line lubricator should be regularly checked and

filled with a good grade of 10W machine oil. Never use a

heavy oil, as this will cause a loss of efficiency. Proper

adjustment of the in-line lubricator is performed by placing

a sheet of paper next to the exhaust ports and holding the

throttle open for approximately 30 seconds. The lubricator

is properly set when a light stain of oil collects on the paper.

Excessive amounts of oil should be avoided.

Eye protection must be worn when disassembling tool or when air line is turned on. A

self-relieving valve in close proximity to the repair station to bleed off air is recom-

mended.

INSTALL RETAINER WITH

CHISEL ONTO BARREL WHILE

ALIGNING SLOT IN RETAINER

WITH GROOVE ON BARREL.

INSERT CHISEL INTO

RETAINER AND ROTATE

RETAINER 1/4 TURN

(90°) IN EITHER DIRECTION.

INSERT SPRING INTO SLOT

IN RETAINER UNTIL ONLY

TAB ON SPRING IS EXPOSED.

TAB

LOCK SPRING

BARREL

RETAINER

CHISEL

STANDARD RETAINER

GROOVE

SLOT

WARNING

!

WARNING

!

Loading...

Loading...