APOLLO HIGH PRESSURE SUPPLIED-AIR RESPIRATOR Page 8

HELMET MODEL 600

© 2011 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com

Manual No. 23930

4.2.3 Cylinders must be equipped with a properly

maintained pressure reducing valve that reduces

pressure to the approved pressure range of the

respirator. See 4.4.

4.3 Breathing-Air from Compressors

4.3.1 The employer shall ensure that air from

compressors used to supply breathing air to respirators

meets the requirements in 29 CFR 1910.134.(i)(5).

4.3.2 Precautions must be taken to prevent

contaminants from entering through the compressor

intake: Ref. 29 CFR 1910.134.(i)(5)(i). The compressor

inlet must be located away from all sources of toxic

contaminants including carbon monoxide, which is found

in engine exhaust (including the exhaust from the

compressor’s engine), and in any form of combustion.

No vehicles should be allowed near the compressor

intake. Contaminants can enter respiratory equipment

through the compressor air inlet. This inlet must not be

located near any exhaust system outlet, ventilation flue,

or source of fumes or particles of any kind.

4.3.3 The compressed-air supply system must be

equipped with suitable in-line air-purifying sorbent beds

and filters, and be maintained to further ensure

breathing air quality: 29 CFR 1910.134 (iii).

4.3.4 If the breathing-air supply is from a non-oil-

lubricated compressor, the employer shall ensure that

the carbon monoxide levels in the breathing air do not

exceed 10 ppm: 29 CFR 1910.134 (i)(6).

4.3.5 If an oil-lubricated compressor is used, the

employer shall use a high-temperature alarm or carbon

monoxide (CO) alarm, or both, to monitor carbon

monoxide levels. If only high-temperature alarms are

used, the air supply shall be monitored at intervals

sufficient to prevent carbon monoxide in the breathing

air from exceeding 10 ppm: 29 CFR 1910.134 (i)(7).

S-Special or Critical User’s Instructions

4.4 Air Volume and Pressure

4.4.1 Operating Pressure

4.4.1.1 HP respirators operate within the pressure

range of 65 and 100 psi (pounds per square inch), as

shown in the table in this section. Maintaining the correct

operating pressure at the point of attachment ensures

the correct air flow to the respirator.

4.4.1.2 The Clemco CPF Inline Particulate Filter with

regulator meets this requirement for a regulator and

gauge, provided the inlet pressure does not exceed 150

psi. See typical installation, Figure 1.

DANGER

Do not connect the Apollo Respirator or CPF

Filter, or any other regulator or filter, to bottled-

air that does not have a pressure reducing

valve that reduces pressure to the maximum

operating pressure of the respirator of filter it

services. Failure to comply with this warning

will cause devices rated at lower pressures to

explode under the high pressure of bottled-air,

and cause severe injury or death.

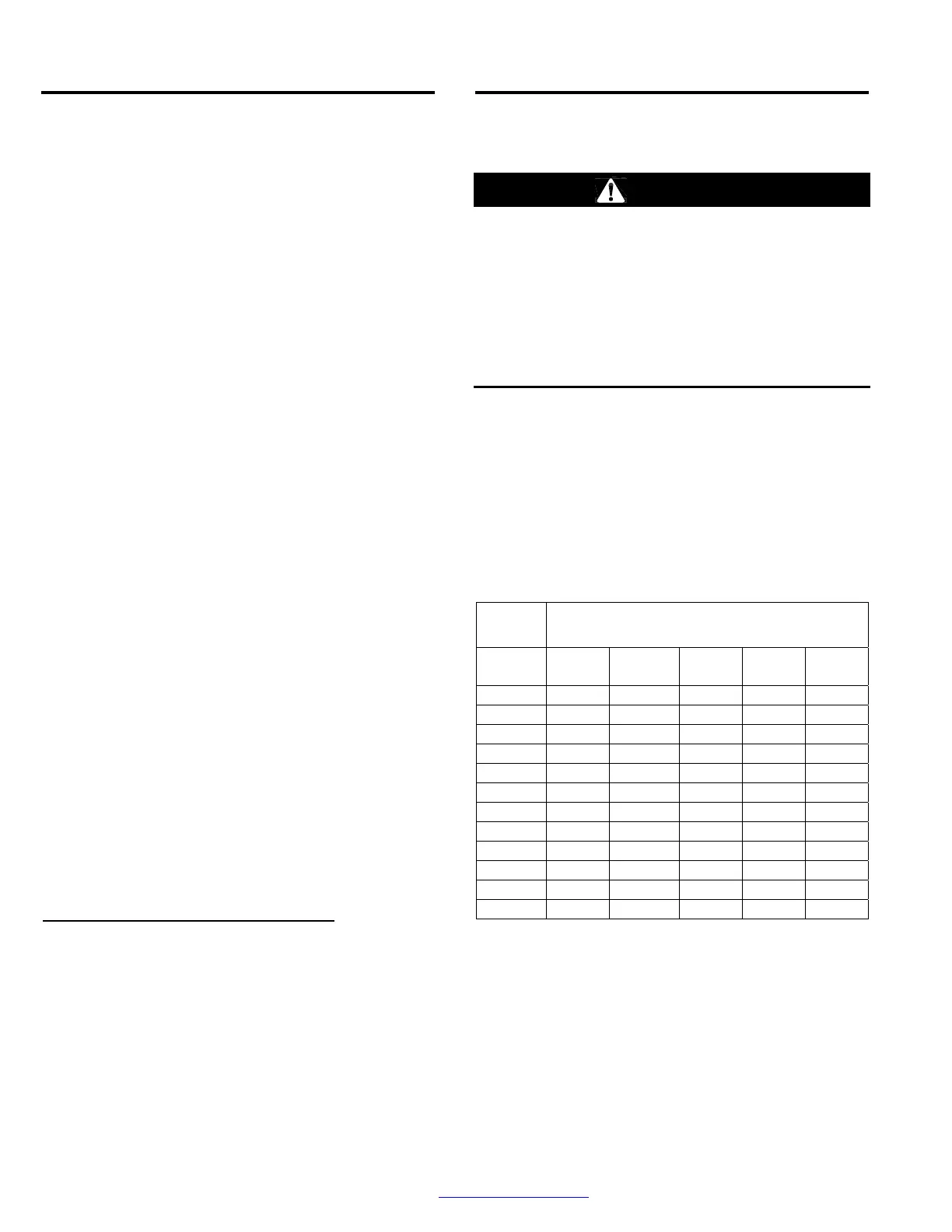

4.4.1.3 Use the following table to determine the

minimum pressure settings and maximum respirator

hose length, based on the air-control device as shown in

Section 2.1.1. Adjust the pressure with the respirator

hose and respirator attached. If the regulator is adjusted

with static pressure (no air flow), pressure may drop

below the required pressure when the respirator is

connected, and may result in low air flow. Setting the

pressure as instructed will provide a minimum of 7 cfm to

the respirator.

Hose

Length Minimum Pressure Setting, psi

CFC

ACV

Clem-

Cool

CAT

CCT

25 ft. 65 85 90 90 90

50 ft. 65 85 90 90 90

75 ft. 65 85 90 90 90

100 ft. 65 85 95 95 95

125 ft. 70 90 95 95 95

150 ft. 70 90 95 95 95

175 ft. 70 90 95 95 95

200 ft. 70 90 95 95 95

225 ft. 75 95 * * *

250 ft. 75 95 * * *

275 ft. 75 95 * * *

300 ft. 75 95 * * *

NOTE: Use any combination of hose shown to provide a

maximum of 300 ft., but not to exceed 12 individual hose

lengths.

* Do not use these control devices at distances

greater than 200 ft.

4.4.2 Air Volume

4.4.2.1 When using a CFC constant-flow connector or

ACV air valve, the respirator must be supplied with 15

cfm (cubic feet per minute) of Grade D breathing air at

Loading...

Loading...