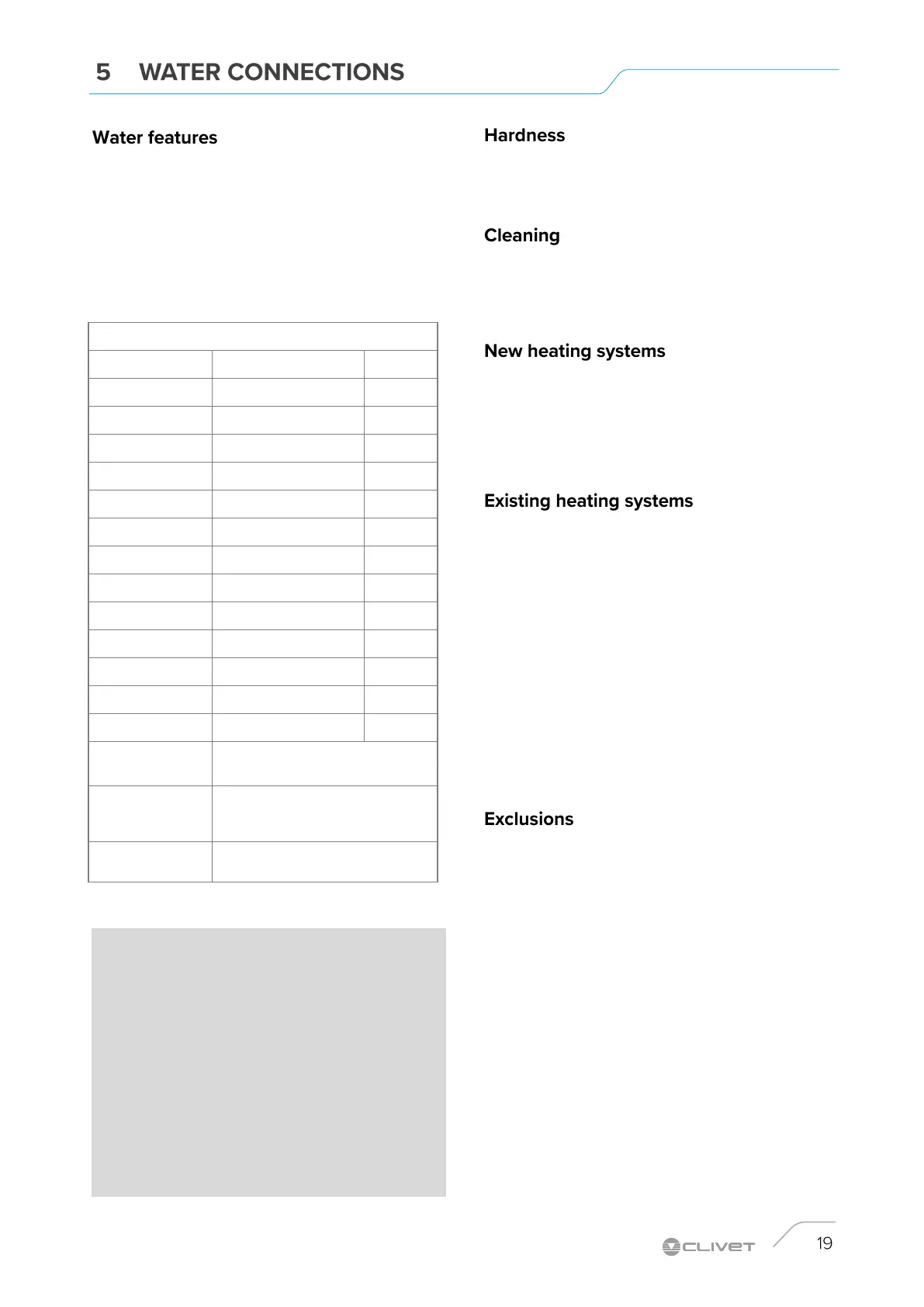

Water component for corrosion limit on Copper

PH 7,5 ÷ 9,0

SO

4

--

< 100

HCO

3

-

/ SO

4

--

> 1

Total Hardness 8 ÷ 15 °f

Cl- < 50 ppm

PO

4

3-

< 2,0 ppm

NH

3

< 0,5 ppm

Free Chlorine < 0,5 ppm

Fe

3

+

< 0,5 ppm

Mn

++

< 0,05 ppm

CO

2

< 50 ppm

H

2

S < 50 ppb

Temperature < 65 °C

Oxygen content < 0,1 ppm

Sand

10 mg/L

0.1 to 0.7mm max diameter

Ferrite hydroxide

Fe3O4 (black)

Dose < 7.5 mg/L 50% of mass

with diameter < 10 µm

Iron oxide Fe2O3

(red)

Dose < 7.5mg/L

confirming to local regulations

Langelier (IL) index between 0 and +0.4

within the limits indicated by table

The water quality must be checked by qualified personnel.

CAUTION

Circulators operate best with clean, good quality tap water.

The most frequently occurring factors which may have a

negative effect on heating water can be oxygen, lime,

sludge, acidity level and other substances (including

chlorides and minerals).

In addition to the heating water quality, the installation also

plays a significant part.

If the water hardness is high install a system suitable to

preserve the unit from harmful deposits and limestone

formations.

If necessary, fit a water softener to reduce water hardness.

Before making the water connections to unit clean carefully the

system with specific and effective products for removing

residues or impurities that could affect the operation. The

existing systems must be free from sludgs, contaminants and

protected against foulings.

In the case of new installations, it is first of all crucial to flush

the entire installation thoroughly (without the circulator

mounted) before the central installation is commissioned. This

will remove residues from the installation process (weld, slag,

fitting products…) and preservatives (including mineral oil).

The system shall then be filled with clean, good quality tap

water.

If a new boiler or heat pump is being installed in an existing

heating system, the system must be flushed to avoid particles

presence, sludge and other problems in the installation. Where

applicable, flushing shall be done before the new application is

installed. Loose dirt can only be removed where there is

sufficient flow. Flushing will therefore take place section by

section. Special attention must also be paid to “blind spots”,

where there is only a small amount of flow and where a lot of

dirt can be accumulated. The system shall then be filled with

clean, good quality tap water. If after the flushing the quality of

the water in an existing installation still proves to be

inadequate, certain measures must be taken to avoid

circulator problems. One option for removing pollution is to

install a filter. Various kinds of filters are available for this. A

screen filter is designed to trap large dirt particles. This filter is

usually placed in the full flow part of the system. A fabric filter

on the other hand, is designed to trap finer particles.

The warranty does not cover damages caused by limestone

formations, deposits and impurities from the water supply and /

or failure from failed system clearing to clean system.

Loading...

Loading...