8

Step 6

Install the included

1

/4" insert bit (or a

7

/16" socket)

in a medium duty drill: 1000-2500 RPM, (2-4 AMP)

variable-speed and reversible. Set the drill to

FORWARD (clockwise as you point the drill away

from you). Keep this drill and a

3

/16" hex key handy

for Steps 8 and 9.

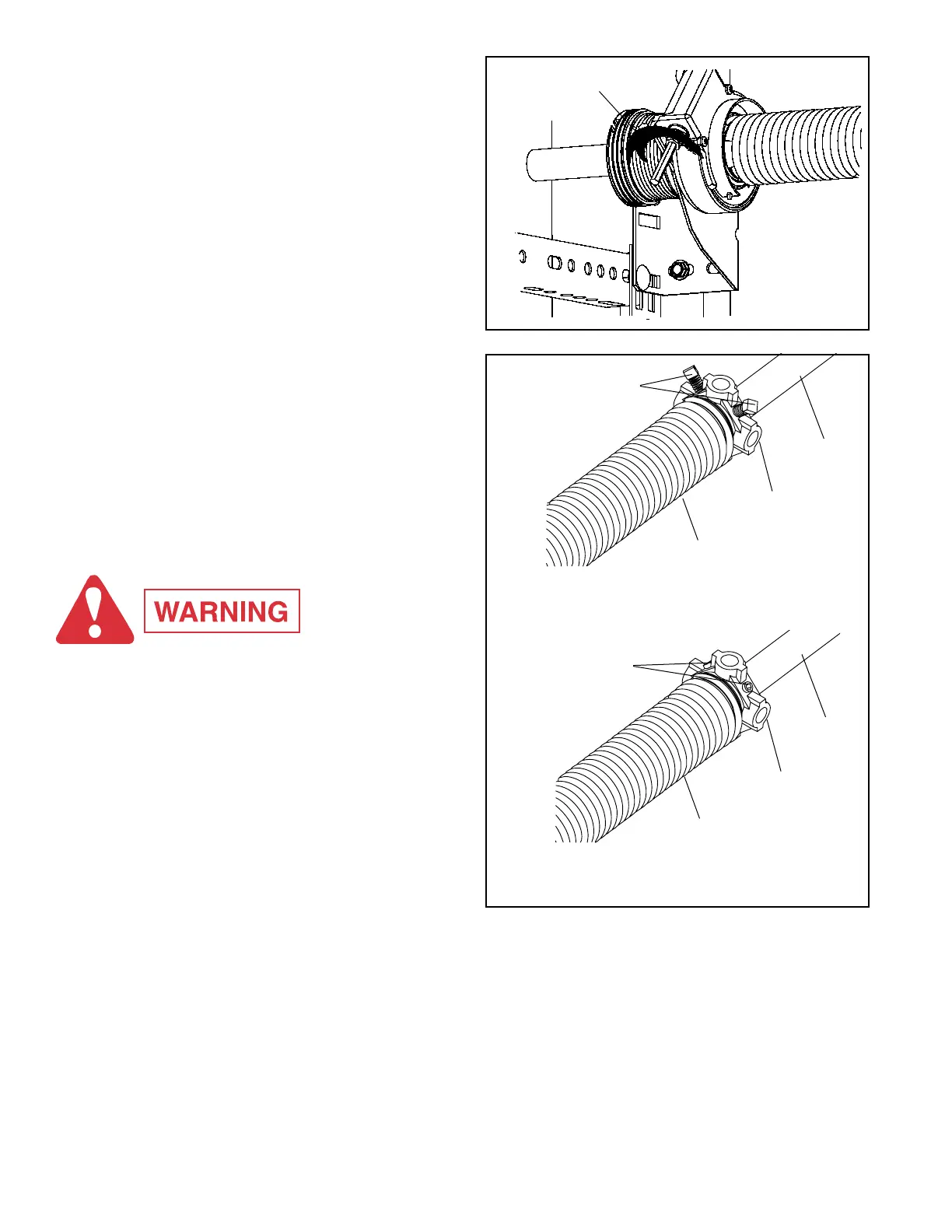

If the stripe on each spring is not facing toward

you as shown in Figure 12, engage the drill with the

1

/4" insert bit (or

7

/16" socket) into drive shaft of the

winding unit to rotate the spring until the stripe is

facing you. (FIG. 12)

NOTE: The

1

/4" insert bit shown in Figure 12

is secured in a drill chuck, but the drill is not

shown.

IMPORTANT!

Step 7

Holding the tube in place, measure and adjust

the length of the spring to match the length you

recorded in Figure 5.

NOTE: THIS LENGTH SHOULD NOT BE LESS THAN

THE RECORDED LENGTH AND SHOULD NOT

EXCEED LENGTH BY MORE THAN 1/2"

DO NOT OVERSTRETCH SPRING(S) BEFORE

TIGHTENING SET SCREWS.

Overstretching the

springs could cause the loss of spring tension

and possibly allow the door to fall. The length

of the spring on the shaft should NOT exceed

the relaxed spring length recorded in Step 3

on page 4 of the EZ - SET

®

Torsion Spring

System Instructions by more than 1/2" max.

NOTE: Be sure to hold the tube in position after

you have tightened the spring set screws. Any

sliding of the tube from this point on will affect

the length of the springs.

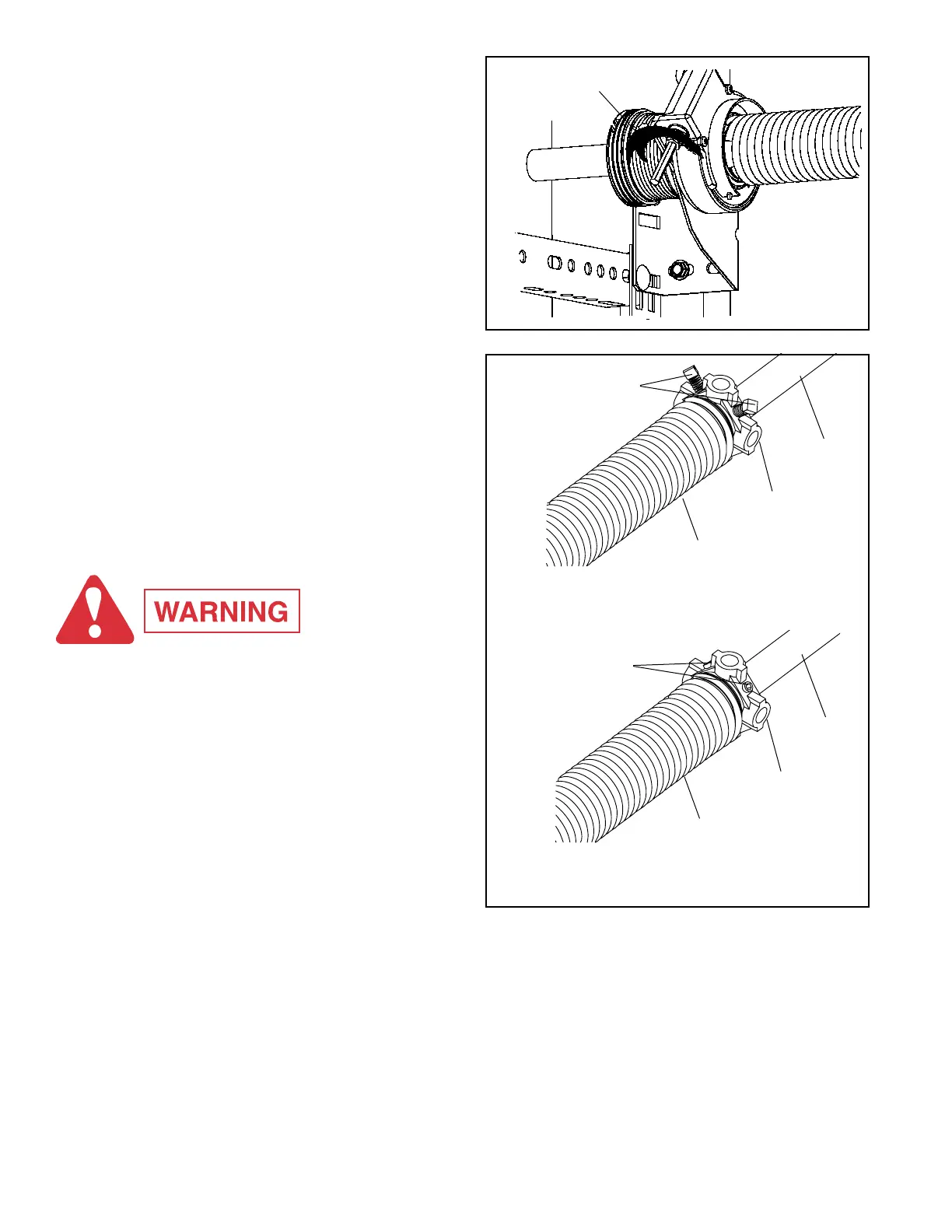

Tighten both set screws in the set cone to the tor-

sion tube. Use a

3

/8" wrench if the springs are sup-

plied with square head set screws as shown

in Figure 13, View A. Use a

3

/16" hex wrench if sup-

plied with internal set screws as shown in Figure 13,

View B. CAUTION: When resistance is encountered

while tightening the set screw, the screw has made

contact with the tube. Set screws should be turned

from

3

/4 to one full turn after they have made

contact with the tube. Additional turns may damage

the tube.

Fig. 13

View B

set cone shown with

internal set screws

View A

set cone shown with

square head set screws

External Set

Screws

Torsion Spring

Set Cone

Torsion

Tube

Internal Set

Screws

Torsion Spring

Set Cone

Torsion

Tube

Fig. 12

If you have a door with two springs, repeat the

above procedure for the right side spring.

Clockwise

Winding

Direction

Loading...

Loading...