General information

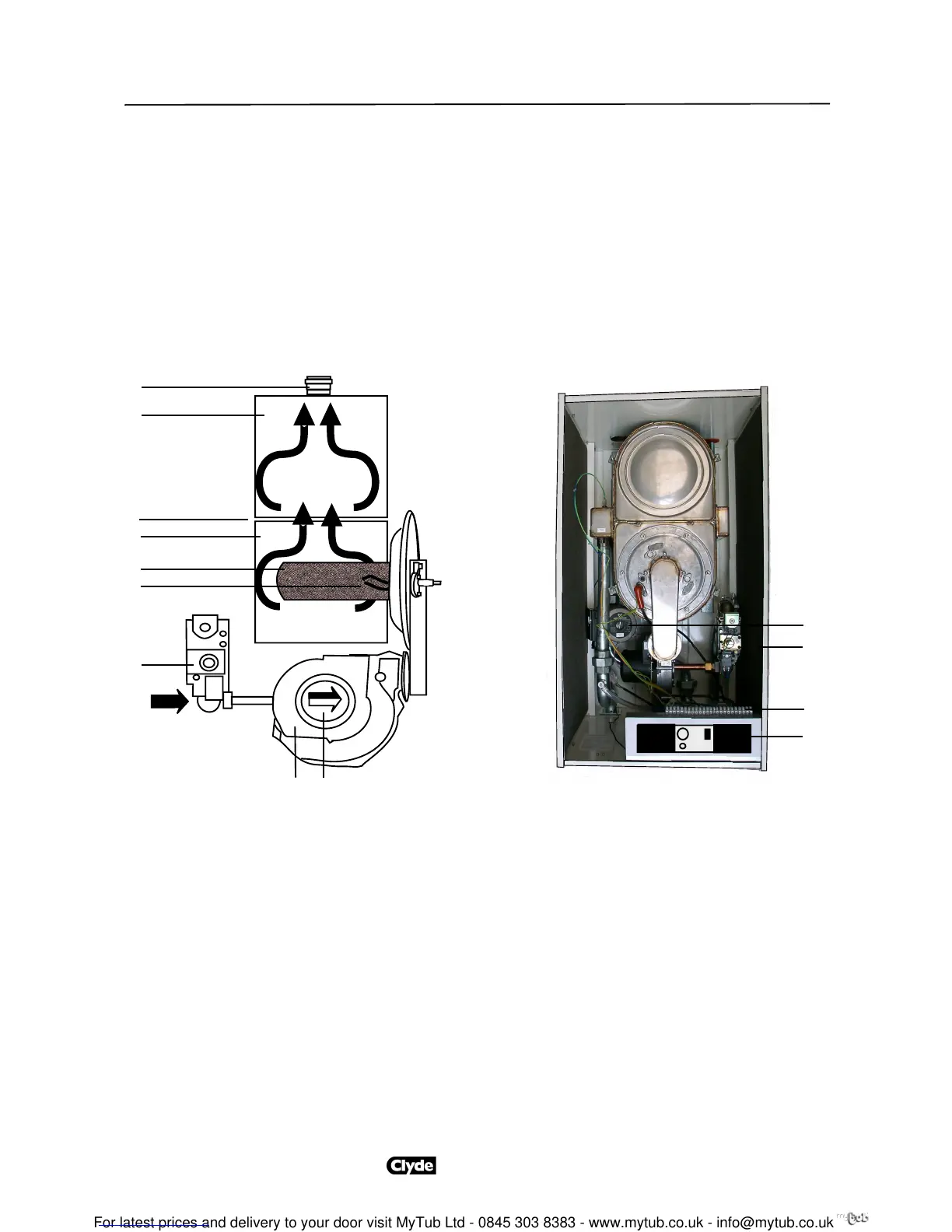

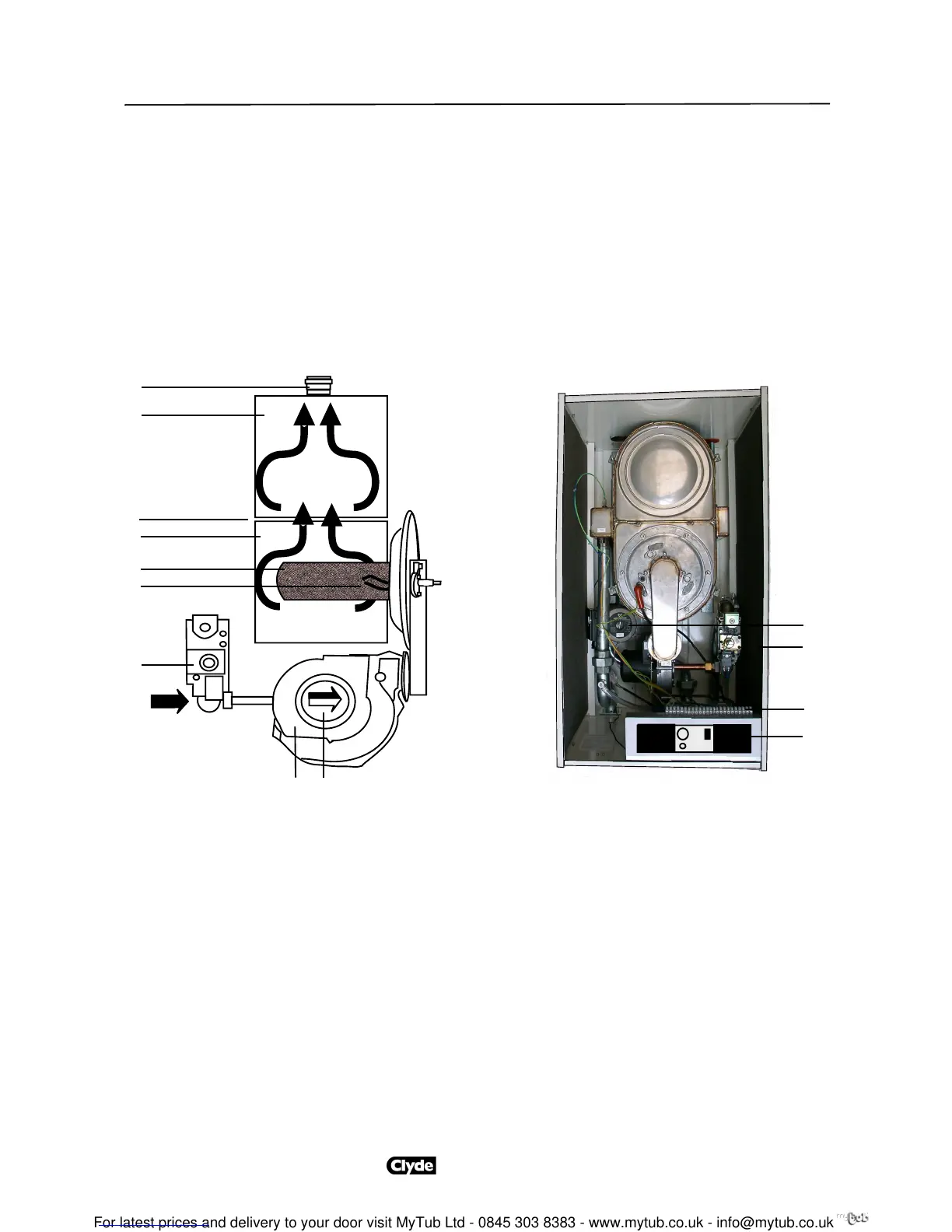

Operating principles

The CG is a wall-mounted condensing boiler with stainless steel counter flow twin heat exchangers (the CG 60 has a

single heat exchanger), pre-mix gas burner and integral flue products fan (refer Figs 1 and 2). When operating in

condensing mode with a flow of 50°C and a return of 30°C, it will give efficiencies of up to 109.5% (ncv). Gas is supplied

through a zero governor valve (2). The air intake fan (4) and venturi (3) accurately control the volumes of gas and air and

mix them prior to ignition. A small flame is held on the entire surface of the burner combustion head (6). This ensures

that there is optimum combustion at any point in the modulation range of the boiler.

System return water is passed through a number of tubes in the secondary (condensing) heat exchanger, and then the

primary heat exchanger. An integral boiler circulation pump (11) ensures an even and constant flow through the heat

exchanger - refer page 8. System circulating pumps should be hydraulically separated from the boiler(s) by a low

velocity header.

Key to Figs 1 & 2

1 Gas supply

2 Gas valve

3 Gas and air mixing by venturi

4 Fan unit

5 Ignition and flame ionisation electrodes

6 Burner head

7 First heat exchanger

8 Baffle plate

9 Second (condensing) heat exchanger

10 Flue gas outlet

11 Boiler circulation pump

12 Sound insulation panels

13 Electrical connection strip

14 Control display

Fig 1 Diagram of operating principles Fig 2 Cut-away CG boiler

1

2

3

4

5

6

7

9

10

8

11

12

13

14

EDS769/4 page2

Loading...

Loading...